Herochu Automatic Bars and Tubes Storage Systems: The Pinnacle of Automated Long Material Handling

For manufacturing facilities, steel service centers, and fabrication shops where long materials like bars, tubes, and profiles represent significant capital and operational expense, traditional storage methods are a primary bottleneck. The logistical challenges of storing, retrieving, and tracking these items consume disproportionate amounts of time, floor space, and labor, while simultaneously introducing substantial safety risks and inventory inaccuracies. The Herochu Automatic Bars and Tubes Storage System has been conceived to eliminate these inefficiencies entirely. This is not a simple storage unit; it is a fully integrated, high-density automated storage and retrieval system (ASRS) engineered to transform your long material management from a costly necessity into a strategic, competitive advantage.

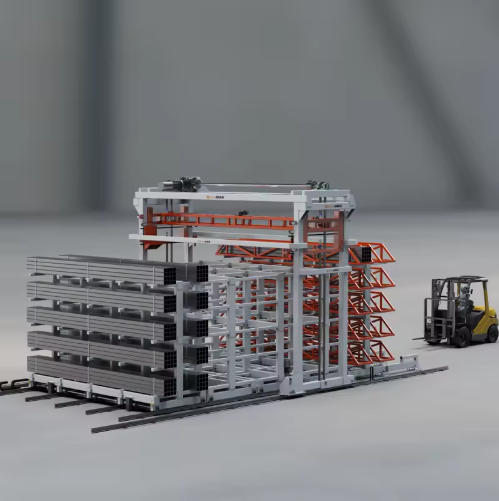

At the heart of this system is a robust and sophisticated automated tower structure, designed for perfect vertical space utilization under meticulously controlled conditions. The core principle is one of unparalleled efficiency and ergonomics: at a command from the user interface, an integrated lift and retrieval unit travels to the designated storage compartment, securely engages the shelf, and transports it from its high-bay location down to a precise, ergonomic working height. This process completely eliminates the need for personnel to climb ladders, operate cranes for small retrievals, or manually handle heavy, cumbersome materials in narrow aisles. After the loading or unloading operation is complete, the system automatically returns the shelf to its optimal storage position, maintaining the integrity and security of the entire inventory.

The operational benefits of this automated process are transformative. By fully utilizing the available room height, the system achieves an extraordinary storage capacity within a remarkably small footprint, effectively multiplying your storage density without requiring a single square meter of additional factory space. Operator safety is fundamentally redefined; the risks associated with manual overhead crane operation and working at height are minimized through fully automated processing, guarded access points, and a comprehensive package of safety sensors that monitor every aspect of the system’s movement. Furthermore, the ergonomic delivery of materials to a comfortable working height drastically reduces physical strain and fatigue, leading to a more productive workforce and a reduction in work-related injuries.

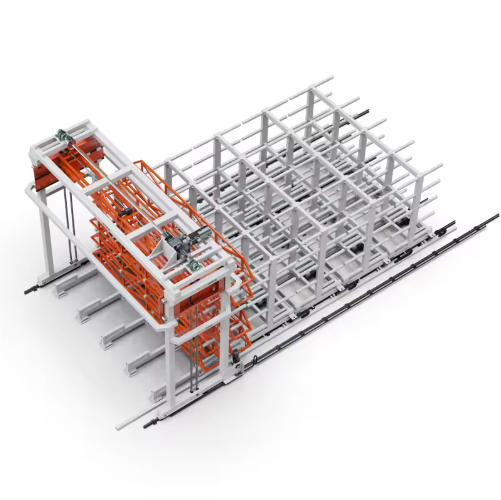

The system’s architecture is built for performance and durability. It consists of a set of loading and unloading gantry systems, high-capacity profile material racks, reinforced material frames, and precision guide rails. The main structure is engineered with a high load-bearing capacity, making it exceptionally sturdy and durable, capable of storing single or bundled profiles of various types and weights. The mode of movement relies on a robust linear guide rail and chain system, with a chain drive transmission ensuring powerful and reliable operation. With a vertical lifting speed of 9 meters per minute and an inlet and outlet speed of 12 meters per minute, the system balances rapid cycle times with smooth, controlled material handling.

Customization is a foundational principle of the Herochu design. The number of layers and the overall quantity of the racks are not fixed; they are meticulously customized according to your factory’s specific dimensions and volume requirements. Standard specifications offer a framework, with tower widths of 6015mm, 6020mm, or 6025mm, spanning 8 to 13 floors, and a load capacity of 3 or 5 tons per layer. Crucially, the storage compartments themselves are highly adaptable. Each compartment can be individually configured to the relevant material requirements, and different usable heights can be realized within a single tower. This allows for separate, organized storage for each type of goods, with optional compartment dividers enabling further individual subdivision to match the typical shipping formats of long goods bundles or unique production needs.

System integration elevates the Herochu Automatic Tower from a storage solution to a central nervous system for your material flow. The simple and time-saving operation is managed through an intuitive touch panel that clearly displays all material information at all times. For ultimate operational transparency and control, an optional link to your ERP system is available. This powerful feature enables a fully automated process from the receipt of a customer order to the dispatch of the goods, providing real-time inventory tracking, automated picking lists, and seamless data exchange that eliminates manual counting and reduces errors to zero.

Manufactured under the most stringent international protocols and bearing CE, EU, and ISO 9001 certifications, the Herochu Automatic Bars and Tubes Storage System guarantees a level of quality, safety, and interoperability that is recognized globally. It represents the definitive investment for businesses aiming to achieve peak efficiency in their long material logistics. As a sophisticated capital asset designed to deliver a rapid return through labor savings, space creation, and inventory accuracy, this advanced system is available starting at $39,998 for a customized configuration. We invite you to schedule a consultation with our automation engineering specialists to conduct a detailed analysis of your workflow and develop a tailored system that will redefine material handling within your operation.