Herochu Cantilever Racks for Light and Heavy Loads: Transform Material Storage From a Bottleneck to a Competitive Edge

In the bustling world of metal fabrication, manufacturing, and construction, your ability to keep raw materials organized and accessible directly dictates how fast—and profitably—you work. You’ve invested in top-tier laser cutters, CNC machines, and skilled teams to meet tight deadlines, but what if the biggest obstacle to efficiency is something far simpler: how you store your long, bulky materials? Pipes, lumber, bar stock, and even large metal sheets stacked haphazardly on the floor or basic pallets don’t just waste space—they create an “efficiency black hole” that costs you time, money, and safety every day.

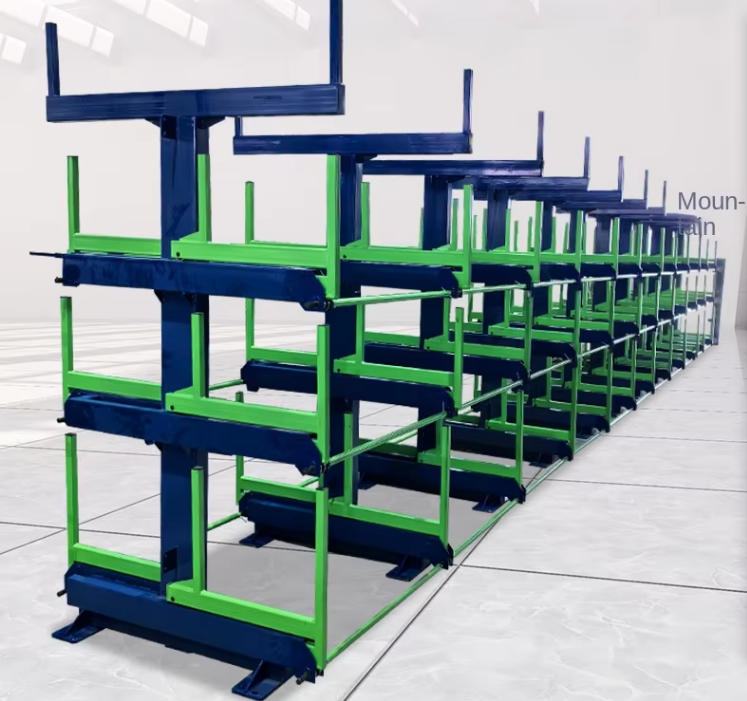

As a leader in industrial storage solutions, Herochu has engineered Cantilever Racks for Light and Heavy Loads to fix this exact problem. CE, UE, and ISO 9001 certified, these racks are built to handle the unique demands of bulk, long-length materials—from 50kg light loads (like aluminum extrusions) to 5,000kg heavy loads (like thick steel pipes). Starting at $3,989 and fully customizable to your workshop’s layout, load needs, and material types, they turn chaotic storage into a streamlined part of your workflow. Let’s break down why Herochu’s cantilever racks are the right choice for workshops that value speed, safety, and savings.

The Hidden Cost of “Making Do” With Poor Storage for Long Materials

If you’re still using floor stacking, basic pallets, or even ill-fitting drawer racks for your long, bulky materials, you’re not just “getting by”—you’re losing money in ways you might not even notice. Here’s the real impact of inefficient storage for items like pipes, bar stock, or large metal sheets:

1. Production Downtime That Drains Revenue

Imagine this scenario: Your team needs a 10ft steel pipe for a construction job. It’s buried under a stack of 20ft aluminum bars and 15ft lumber—all haphazardly piled on the floor. To retrieve it, you have to:

- Divert a forklift operator from another task (delaying that job, too).

- Spend 25 minutes moving the 20ft bars to a temporary spot (risking scratches or dents).

- Shift the 15ft lumber out of the way (another 15 minutes).

- Finally, grab the 10ft pipe (hoping it’s not bent).

- Re-stack the other materials (20 more minutes).

That’s 60 minutes of downtime for a single pipe—time your team could have spent on fabrication, assembly, or client work. For a shop billing 120/hour,that’s120 lost per retrieval. Multiply that by 5–8 retrievals per day, and you’re looking at 600–960 in wasted revenue weekly.

Herochu’s cantilever racks eliminate this. Their open-fronted design lets you access any material in 2–3 minutes—no shifting, no re-stacking, no downtime. Your team stays focused on value-added work, and your revenue stays on track.

2. Material Damage That Wastes Cash

Long, thin materials like pipes or bar stock are surprisingly fragile when mishandled. Stack them on the floor, and they:

- Rub against each other, causing scratches that ruin their finish (especially costly for stainless steel or aluminum).

- Bend under the weight of heavier materials on top (making them unusable for precision jobs).

- Collect dust, moisture, and debris (leading to rust that requires expensive cleaning or replacement).

3. Safety Risks That Endanger Your Team

Maneuvering long, heavy materials in a cluttered space is a recipe for disaster. Every time your team uses a forklift to shift a stack of 20ft steel pipes or climbs on a pallet to reach a top bar, they face risks like:

- Pipes rolling off the stack and crushing feet or equipment.

- Forklifts colliding with nearby machinery while navigating tight spaces.

- Falls from unstable piles while trying to retrieve materials.

A single workplace injury can cost

40,000–120,000 in medical bills, workers’ comp claims, and legal fees. It also shatters team morale and leads to costly turnover. Herochu’s cantilever racks are designed with safety first: wide, stable bases prevent tipping, evenly spaced arms keep materials secure, and the open layout gives forklift operators clear visibility. No more risky maneuvers—just safe, efficient material handling.

How Herochu Cantilever Racks for Light and Heavy Loads Work (And Why They’re Better)

Cantilever racks aren’t new—but Herochu’s design elevates them from a “basic storage tool” to a “workflow optimizer.” Here’s a breakdown of how they function, and why they outperform other storage options for long, bulky materials:

The Basics: How Cantilever Racks Solve Bulk Storage Challenges

A Herochu cantilever rack system consists of three key components:

- Vertical Columns: Heavy-duty steel columns anchored to the floor (or wall, for space-saving setups) that support the entire structure. They’re reinforced with cross-braces for extra stability, even under maximum load.

- Horizontal Arms: Extend outward from the columns (no front supports, unlike traditional shelving) to hold materials. The arms are adjustable—you can move them up or down in 6-inch increments to fit different material lengths and weights.

- Base Plates: Wide, thick steel plates at the bottom of each column that distribute weight evenly across the floor, preventing the rack from sinking or tipping (critical for heavy loads).

This open-fronted design is a game-changer for long materials. Unlike drawer racks (which work well for small sheets but struggle with 15ft+ pipes) or floor stacking (which hides materials), cantilever racks let you see and access every item at a glance. You can load a 20ft steel bar onto the arms with a forklift in 30 seconds, and retrieve a 10ft aluminum extrusion from the same rack just as fast—no shuffling, no delays.

Light vs. Heavy Load: Herochu Racks Adapt to Your Needs

One of the biggest mistakes shops make is buying a “one-size-fits-all” storage system. A rack that works for 100kg aluminum bars will collapse under 5,000kg steel pipes—and a rack built for heavy loads will waste space if you only store light materials. Herochu solves this with two specialized lines:

1. Light Load Cantilever Racks (50kg–1,000kg per arm)

Ideal for: Aluminum extrusions, thin steel bars, lumber, plastic sheets, or small bundles of metal.

Key features:

- Slimmer columns (3x3in steel) to save space in compact workshops.

- Lightweight but durable arms (1.5in thick steel) with optional rubber padding to protect delicate surfaces.

- Wall-mounted or freestanding options (wall-mounted saves even more floor space).

Perfect for: Small fabrication shops, woodworking studios, or businesses that handle lightweight, high-volume materials.

2. Heavy Load Cantilever Racks (1,000kg–5,000kg per arm)

Ideal for: Thick steel pipes, large metal sheets (4x10ft+), concrete beams, or heavy industrial bundles.

Key features:

- Thick, reinforced columns (6x6in steel) with double cross-braces for maximum stability.

- Heavy-duty arms (3in thick steel) with anti-slip surfaces to prevent materials from shifting.

- Extra-wide base plates (24x12in) to distribute weight and avoid floor damage.

Perfect for: Large manufacturing facilities, construction yards, or shops that work with heavy, high-value materials.

No matter which line you choose, every Herochu cantilever rack is built with cold-rolled steel (thicker than industry standards) and welded with precision. They’re designed to withstand daily use for 15+ years—so you won’t need to replace them every 2–3 years like cheap, generic racks.

When to Choose Cantilever Racks (And When to Avoid Them)

Not every storage system works for every shop—and Herochu is honest about when our cantilever racks are the best fit (and when they’re not). Here’s a clear breakdown to help you decide:

When Cantilever Racks Shine

- You store long, bulky materials: If your inventory includes items longer than 8ft (pipes, bars, large sheets), cantilever racks are the most efficient option. Their open design eliminates the “length problem” that plagues drawer racks or traditional shelving.

- You need LIFO (Last-In, First-Out) access: If you receive large shipments of the same material (e.g., a 50-bundle order of steel pipes) and use them in the order you receive them, cantilever racks work perfectly. You load the newest bundle on top, and unload it first—no shuffling.

- You value space efficiency: Cantilever racks use vertical space better than floor stacking (you can stack materials 10ft+ high) and have no front supports, so you can fit more racks in the same floor space. For shops in urban areas (where rent is high) or small facilities, this is a lifesaver.

- You use forklifts or overhead cranes: Cantilever racks are designed to work with your existing equipment. You can load and unload materials with a forklift in seconds—no need for specialized tools.

When to Consider a Different System

- You need FIFO (First-In, First-Out) access: If you need to use the oldest material first (e.g., perishable metals or time-sensitive orders), a drawer rack or push-back system might be better. Cantilever racks are optimized for LIFO.

- You store small, diverse materials: If your inventory is mostly small sheets (4x4ft or smaller) or tiny parts, a drawer rack or bin system will offer better selectivity. Cantilever racks are built for bulk, not small-item organization.

- You have no forklift or crane: Cantilever racks are designed for machine-assisted loading/unloading. If you only use manual labor, a lighter system (like basic shelving) might be more practical.

At Herochu, we don’t just sell you a rack—we help you choose the right system for your needs. Our team will assess your inventory, workflow, and equipment to make sure you get a storage solution that solves your specific problems.

Customization: Herochu Builds Cantilever Racks for Your Workshop

No two shops are the same—and a “standard” cantilever rack will never work as well as one built for your space. Herochu offers full customization for every rack, so you can tailor it to your exact needs:

1. Size Customization

- Height: Choose from 6ft (compact shops) to 20ft (high-ceiling facilities) to maximize vertical space.

- Arm Length: 4ft, 6ft, 8ft, or custom lengths (up to 12ft) to fit your longest materials.

- Number of Arms: 2–10 arms per column (depending on how much you need to store).

2. Layout Customization

- Freestanding: Perfect for open workshops—racks can be placed anywhere, and you can access materials from both sides.

- Wall-Mounted: Saves floor space by attaching to your workshop walls—ideal for small shops or narrow aisles.

- Double-Sided: Columns with arms on both sides (great for high-volume storage—doubles capacity without doubling floor space).

3. Material-Specific Add-Ons

- Padding: Rubber or foam padding on arms to protect delicate materials (aluminum, plastic, or finished wood).

- Anti-Slip Surfaces: Grip tape on arms to prevent heavy materials (steel pipes, concrete) from shifting.

- Weatherproofing: Powder-coated finish and rust-resistant hardware for outdoor storage (construction yards, lumberyards).

- Label Holders: Metal or plastic holders to tag each arm (so your team can find materials even faster).

Our customization process is simple:

- Consultation: We send a team to your workshop (or do a virtual walkthrough) to measure your space, review your materials, and understand your workflow.

- Design: We create a 3D rendering of your custom rack—so you can see exactly how it will fit, how much it will hold, and how it will integrate with your equipment.

- Approval: You review the design and make any changes (no extra cost for adjustments).

- Manufacturing: We build your rack in our ISO 9001-certified facility, using high-grade steel and precision welding.

- Installation: Our team delivers and installs the rack (usually in 1 day for small systems, 2–3 days for large ones) and trains your team to use it safely.

No surprises, no compromises—just a cantilever rack that works for your shop.

The ROI of Herochu Cantilever Racks (It Pays for Itself in Months)

Investing in a professional cantilever rack isn’t an expense—it’s a way to make money by eliminating waste. Let’s crunch the numbers for a medium-sized fabrication shop that stores 100+ steel pipes and bars:

| Benefit | Monthly Impact | Annual Impact |

| Reduced Downtime | +4,800(4extrahoursofproductionperdayat120/hour) | +$57,600 |

| Lower Material Damage | -875(from1,458 to $583 in wasted metal) | -$10,500 |

| Fewer Labor Hours | -$2,000 (1 less worker needed for material handling) | -$24,000 |

| Saved Rent (Space Savings) | -900(60sqftsavedat15/sq ft/year) | -$10,800 |

| Net Annual Gain | +$1,025 | +$12,300 |

Real Results: What Herochu Customers Say About Our Cantilever Racks

Don’t just take our word for it—here’s how our cantilever racks have transformed real businesses:

“Before Herochu, we spent 3 hours every day moving steel pipes around. Our forklift operator was tied up just shuffling materials, and we lost $1,200 a week in downtime. Now, we retrieve any pipe in 2 minutes, and the forklift is free to handle other jobs. We added 15% more production capacity without hiring anyone new.”

— John D., Owner of MetalFab Inc. (Houston, TX)

“We used to lose $12,000 a year to bent and scratched aluminum extrusions. Herochu’s light load cantilever racks with padding stopped that completely. Plus, we freed up 80 sq ft of floor space—enough to add a new woodworking station. The rack paid for itself in 3 months.”

— Lisa M., Operations Manager at Allied Builders (Phoenix, AZ)

“Safety was our biggest issue. We had a near-miss when a steel pipe rolled off a floor stack and almost hit a worker. Herochu’s heavy load racks keep pipes secure, and the open layout lets our forklift operator see everything. No more accidents, and our workers’ comp rates dropped by 20%.”

— Mike S., Plant Manager at Industrial Steelworks (Philadelphia, PA)

Why Choose Herochu for Cantilever Racks for Light and Heavy Loads?

There are plenty of companies that sell cantilever racks—but only Herochu combines expertise, quality, and support to give you a system that lasts:

- Expertise: We’ve been building industrial storage solutions for 15+ years. We know the unique challenges of storing long, bulky materials because we work with fabrication shops, construction yards, and manufacturers every day. We don’t just sell you a rack—we solve your storage problem.

- Quality: Every Herochu cantilever rack is CE, UE, and ISO 9001 certified. We use high-grade cold-rolled steel (thicker than competitors) and test every rack to 120% of its load capacity before shipping. You won’t find cheap, flimsy parts here—just a system built to last.

- Support: We don’t disappear after installation. Our team offers 24/7 technical support (call or email, and we’ll respond within 1 hour). We stock replacement parts for all our racks (shipped within 48 hours for most regions), and we provide annual maintenance checks to keep your system running like new.