Choosing the Right Cantilever Rack: Key Factors for Single vs. Double-Sided | Herochu

Every workshop, warehouse, or fabrication facility faces a unique set of storage challenges—especially when it comes to bulky, long, or irregularly shaped items like sheet metal, steel plates, lumber, or piping. Cantilever racks have emerged as a go-to solution for such storage needs, but with two primary configurations—single-sided and double-sided—selecting the right one can feel overwhelming. At Herochu, we understand that the perfect storage system isn’t a one-size-fits-all solution. That’s why our CE, UE, and ISO 9001 certified cantilever racks are fully customizable to your workshop’s layout and requirements, starting at just $4,899. In this guide, we’ll break down the critical differences between single-sided and double-sided cantilever racks, explore the key factors to consider, and help you make an informed decision that boosts efficiency, maximizes space, and aligns with your budget.

At a Glance: Single-Sided vs. Double-Sided Cantilever Racks

Before diving into the details, let’s start with a quick comparison to highlight the core distinctions between these two rack types:

| Feature | Single-Sided Cantilever Racks | Double-Sided Cantilever Racks |

| Design | Wall-mounted with arms on one side | Free-standing with arms on two sides |

| Storage Capacity | Half the capacity of double-sided models | Double the capacity of single-sided models |

| Space Requirements | Ideal for tight, narrow spaces | Best suited for open, spacious areas |

| Cost | Lower initial investment due to simpler design | Higher initial investment, justified by increased capacity and structural integrity |

| Accessibility | Accessible from one side only | Accessible from both sides for improved workflow |

Detailed Comparison: Design, Capacity, and Functionality

1. Design and Structure: Wall-Mounted vs. Free-Standing

The most fundamental difference between single-sided and double-sided cantilever racks lies in their design and installation. Single-sided cantilever racks are engineered to be wall-mounted, featuring sturdy arms extending from one side of the frame. This design leverages existing wall structures for stability, eliminating the need for additional support and making them an excellent choice for facilities where floor space is at a premium. The compact profile of single-sided racks allows them to fit snugly against walls, keeping walkways and operational areas clear.

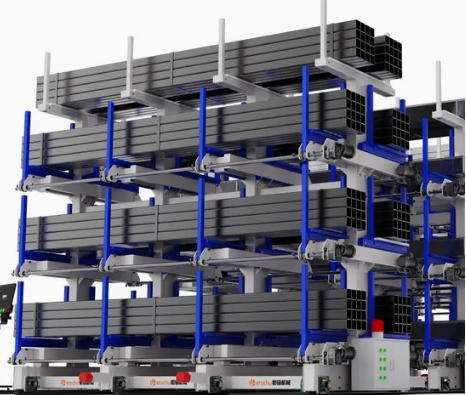

On the other hand, double-sided cantilever racks are free-standing units with arms protruding from both sides of the central frame. This self-supporting design means they don’t require wall mounting, giving you greater flexibility in warehouse layout. The double-sided configuration is built for durability, with reinforced frames to handle the increased weight and stress of holding materials on two sides. These racks are often used in large, open warehouses where maximizing storage density is a top priority, as they can be arranged in rows to create efficient storage aisles.

2. Storage Capacity: Maximizing Space for Your Needs

When it comes to storage capacity, the difference between the two rack types is straightforward: double-sided cantilever racks offer twice the storage capacity of their single-sided counterparts. Single-sided racks are designed for smaller-scale storage needs, making them perfect for workshops or warehouses that handle moderate volumes of materials or have limited space. For example, a small metal fabrication shop that primarily works with custom orders and smaller batches of sheet metal might find single-sided racks sufficient to keep their inventory organized without taking up unnecessary space.

Double-sided cantilever racks, however, are built for high-volume storage. Their dual-arm design allows them to hold significantly more materials, making them ideal for large facilities, distribution centers, or manufacturing plants that process large quantities of long or heavy items. If your business deals with bulk orders, maintains a large inventory, or is planning for expansion, a double-sided rack system can help you maximize your storage density without expanding your facility’s footprint. The increased capacity also translates to fewer racks needed, which can streamline operations by reducing the time spent moving between storage areas.

3. Space Requirements: Fitting Racks to Your Facility Layout

Your warehouse or workshop’s available space is a critical factor in choosing between single-sided and double-sided cantilever racks. Single-sided racks excel in tight, narrow spaces where every square foot counts. Their wall-mounted design means they don’t take up floor space in the middle of the room, making them perfect for small workshops, narrow aisles, or facilities with irregular layouts. For instance, a urban woodworking studio with limited square footage can use single-sided racks to store lumber against the walls, leaving the central area free for cutting, assembly, and other core operations.

Double-sided racks, by contrast, require more open space to function effectively. Because they’re accessible from both sides, they need clear aisles on either side to allow for easy loading and unloading—typically with forklifts or pallet jacks. This makes them better suited for large, open warehouses or facilities with wide aisles. If your facility has ample floor space and you need to store large volumes of materials, double-sided racks can help you create efficient storage zones that minimize travel time and boost productivity. Additionally, their free-standing design allows you to reconfigure them as your layout needs change, providing long-term flexibility.

4. Cost: Balancing Initial Investment with Long-Term Value

Budget is always a key consideration when investing in storage equipment, and single-sided and double-sided cantilever racks differ significantly in terms of initial cost. Single-sided racks are more affordable upfront, thanks to their simpler design, fewer materials, and reliance on wall support. This lower initial investment makes them an attractive option for small businesses, startups, or facilities with limited capital. If your storage needs are modest and you’re looking for a cost-effective solution to organize your inventory, single-sided racks offer excellent value without compromising on quality—especially when you choose Herochu’s certified models.

Double-sided cantilever racks come with a higher initial price tag, but this investment is often justified by their superior storage capacity, structural integrity, and long-term efficiency. The reinforced frame, dual arms, and free-standing design require more materials and engineering, but the benefits are substantial. For businesses with high storage demands, the increased capacity of double-sided racks can reduce the need for additional storage equipment, lowering long-term costs. Additionally, the improved accessibility and workflow efficiency can translate to time and labor savings, further enhancing the return on investment. When evaluating cost, it’s important to look beyond the initial purchase price and consider the long-term value each rack type brings to your operation.

5. Storage Efficiency and Accessibility: Streamlining Your Operations

Storage efficiency isn’t just about capacity—it’s also about how easily you can access and manage your inventory. Single-sided cantilever racks are designed for efficient storage in space-constrained environments, with a focus on keeping materials organized and within reach. Their wall-mounted position means materials are stored off the floor, reducing the risk of damage and making it easier to inspect and retrieve items. However, since they’re only accessible from one side, they’re best suited for facilities where materials are retrieved from a single direction—such as along a wall or narrow aisle.

Double-sided cantilever racks prioritize both capacity and accessibility. With arms on two sides, they allow for bidirectional access, making it faster and easier to load and unload materials. This is particularly beneficial for high-volume operations where time is of the essence, as forklift operators can access materials from either side of the rack without having to maneuver around to the opposite end. The free-standing design also allows for better airflow and visibility, making it easier to inventory materials and maintain organization. For facilities that handle large quantities of heavy or long items, the improved accessibility of double-sided racks can significantly reduce downtime and boost overall productivity.

Key Factors to Consider When Making Your Choice

Now that we’ve explored the differences between single-sided and double-sided cantilever racks, let’s break down the critical factors you should evaluate to make the right choice for your business:

1. Available Space and Facility Layout

Start by assessing your facility’s layout and available space. Measure the dimensions of your warehouse or workshop, including wall space, aisle width, and ceiling height. If you have limited floor space or narrow aisles, single-sided cantilever racks are likely the better option, as they can be mounted against walls to save space. If you have a large, open facility with wide aisles, double-sided racks can help you maximize storage density and create efficient workflow patterns.

2. Storage Needs and Inventory Volume

Next, evaluate your storage requirements. Consider the volume, weight, and size of the materials you need to store. If you handle small to moderate volumes of lightweight or medium-weight items, single-sided racks may be sufficient. If you deal with large quantities of heavy, long, or bulky materials—such as steel plates, industrial piping, or large lumber beams—double-sided racks will provide the capacity and durability you need. It’s also important to consider future growth: if your business is expanding, investing in double-sided racks now can help you avoid the need for additional storage equipment down the line.

3. Budget and Long-Term ROI

Your budget will play a significant role in your decision, but it’s important to balance short-term costs with long-term value. Single-sided racks offer a lower initial investment, making them a good choice for businesses with limited capital or immediate storage needs. However, if your storage demands are high, double-sided racks can deliver a higher return on investment by reducing labor costs, minimizing downtime, and maximizing storage capacity. Calculate the potential savings from improved efficiency and reduced inventory damage to determine which option makes the most financial sense for your business.

4. Access Requirements and Workflow

Finally, consider how you access and handle your inventory. If your workflow involves retrieving materials from a single direction—such as along a wall—single-sided racks will work well. If you need to load and unload materials from multiple directions or require faster access to large quantities of items, double-sided racks will streamline your operations. Think about the equipment you use to move materials (e.g., forklifts, pallet jacks) and ensure the rack configuration you choose is compatible with your existing workflow.

Why Choose Herochu’s Cantilever Racks?

At Herochu, we’re committed to providing high-quality, customizable storage solutions that meet the unique needs of your business. Our cantilever racks are CE, UE, and ISO 9001 certified, ensuring they adhere to the strictest international standards for quality, safety, and durability. Whether you choose a single-sided or double-sided configuration, our racks are built to withstand heavy loads, resist wear and tear, and provide long-lasting performance.

What sets Herochu apart is our focus on customization. We understand that every facility is different, which is why we work closely with you to design a cantilever rack system that fits your specific layout, storage needs, and budget. Starting at just $4,899, our racks are accessible to businesses of all sizes, from small workshops to large-scale manufacturing plants. Our team of experts will guide you through the entire process—from initial assessment and design to installation and maintenance—ensuring a seamless experience and a storage solution that delivers real results.

Conclusion: Make the Right Choice for Your Business

Choosing between single-sided and double-sided cantilever racks is a decision that impacts your facility’s efficiency, storage capacity, and bottom line. By evaluating your available space, storage needs, budget, and workflow, you can select the configuration that best aligns with your business goals. Whether you opt for the space-saving efficiency of single-sided racks or the high-capacity accessibility of double-sided racks, Herochu’s customizable, certified solutions are designed to help you organize your inventory, streamline your operations, and maximize your profitability.

Don’t let disorganized storage hold your business back. Contact Herochu today to schedule a free facility assessment. Our team will help you determine the perfect cantilever rack configuration for your needs, provide a detailed quote, and show you how our storage solutions can transform your workshop or warehouse. Invest in the right cantilever rack system and take the first step toward a more efficient, productive, and profitable operation.