Don’t Let Racking Ruin Your Revenue | Herochu Racks Designed for Delicate Metals

For fabricators working with mirror-finish stainless steel, brushed aluminum, or any high-finish metal, a single scratch isn’t just a cosmetic flaw—it’s a direct hit to your bottom line. Every damaged panel means scrap, rework, wasted machine time, and missed deadlines. Conventional storage—stacking sheets haphazardly, forcing operators to “dig and flip” to find what they need—turns your most valuable materials into profit risks. That’s why Herochu engineered a better solution: scratch-resistant racks built exclusively for delicate metals. Customizable to your workshop, CE/UE/ISO 9001 certified, and starting at just $4,399, this isn’t just storage—it’s protection for the assets that keep your business profitable.

The Hidden Cost of “Good Enough” Racking for High-Finish Metals

You know the drill: a new shipment of mirror-finish stainless arrives, and you stack it alongside existing sheets to save space. A week later, an operator needs one panel—so they drag the top sheets aside, scraping against the ones below. The result? A deep scratch across the mirror surface. Suddenly, that $500 panel is worthless. But the damage doesn’t stop there. That single scratch costs you three times over:

1. Direct Scrap & Rework Costs

First, you absorb the cost of the material itself—money spent on metal that will never reach a client. Then, you pay for labor: either an operator spends hours trying to buff out the scratch (with no guarantee of success) or you discard the panel entirely. For high-volume shops, this adds up fast—one scratched sheet per week equals $26,000 in wasted material annually.

2. Wasted Machine & Labor Time

While your team fixes or discards the damaged panel, your laser cutter or press brake sits idle. That’s time you could have used to run a profitable job, fulfill a client order, or take on new work. Meanwhile, the operator who “dug and flipped” the sheets is being paid for work that adds zero value—time spent moving metal, not creating it.

3. Schedule Delays That Erode Client Trust

A scratched panel doesn’t just affect your shop—it ripples outward. If that damaged sheet was for a deadline-driven project, you’re now racing to reorder material, redo cuts, and catch up. Miss the deadline, and you risk losing the client’s trust (and future business). In an industry where referrals and repeat work keep you competitive, that’s a risk you can’t afford.

Conventional stacking isn’t storage—it’s a gamble. And the odds are stacked against you. Herochu’s delicate metal racks eliminate this gamble by designing out the root cause of damage: friction and uncontrolled handling.

What Makes Herochu’s Racks the Ultimate Solution for Delicate Metals?

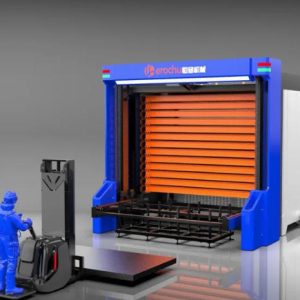

The “ultimate rack” for high-finish metals isn’t just strong—it’s smart. It’s built to ensure every sheet stays scratch-free from the moment it’s unloaded to the second it hits your machine. Herochu’s design checks three critical boxes: 100% selectivity (access any sheet without moving others), zero-friction handling, and total operator control. Here’s how it works:

1. 100% Extendable Drawers: No More “Dig and Flip”

At the core of Herochu’s rack is a set of heavy-duty, 100% extendable drawers engineered from Q235 structural steel—the same material used in industrial beams for maximum durability. Unlike traditional racks where sheets are stacked vertically (and hidden behind one another), each drawer pulls fully outside the frame. This means:

- No more dragging sheets across each other to reach the one you need.

- Unobstructed overhead access for cranes, jib cranes, or vacuum lifters.

- Every sheet is visible and accessible in seconds—no guesswork, no risk.

Imagine needing a 4x8ft mirror-finish stainless panel. Instead of sending an operator to shift five heavier sheets out of the way (and risk scratches), you extend the drawer, lower the vacuum lifter, and lift the exact sheet you need—without it touching any other material. That’s zero friction, zero damage, and zero wasted time.

2. Two Handling Systems: Tailored to Your Load & Flow

High-finish metals come in different weights and volumes—and your rack should adapt. Herochu offers two specialized handling systems to match your workflow:

For Heavy Loads (1.5–3 Tons): Hand-Crank Mechanism

When you’re storing thick, heavy sheets (like 10-gauge stainless steel), uncontrolled movement is a disaster. Our hand-crank system uses a gear-reduction design that lets one operator extend even 3-ton drawers with smooth, minimal effort. No jerks, no sudden shifts—just slow, precise control. This prevents sheets from sliding against each other or bumping the drawer sides (a common cause of micro-scratches). For shops that prioritize precision, this is non-negotiable.

For Production Speed (Up to 4.5 Tons): Forklift-Accessible Drawers

If you’re running high-volume jobs, every second counts. Herochu’s forklift-accessible drawers turn each unit into a “mobile steel pallet.” Instead of moving individual sheets from the rack to the machine, you use a forklift to lift the entire drawer (with the sheet safely secured inside) and transport it directly to your laser cutter or press brake. This cuts handling steps in half: no more loading/unloading sheets twice, no more risk of drops or scrapes during transport. It’s a seamless “rack-to-machine” flow that keeps your production line moving—and your metals flawless.

3. Soft-Contact Surfaces: Protection Where It Matters Most

Even the most careful handling won’t prevent scratches if the rack itself is rough. Herochu lines each drawer with non-abrasive, soft-contact padding that acts as a buffer between the metal and the steel drawer. This padding is resistant to oils, solvents, and moisture (common in fabrication shops) and won’t leave residue on your high-finish metals. Whether you’re storing brushed aluminum (which shows every mark) or mirror-finish stainless (where even a fingerprint is noticeable), this extra layer of protection ensures your sheets stay in “as-new” condition.

4. Compact Design: Maximize Space Without Sacrificing Safety

You don’t have to choose between protecting your metals and using your workshop space efficiently. Herochu’s racks are vertically scalable—customize the number of floors (from 2 to 8) to match your ceiling height—and horizontally configurable (choose from standard widths: 3015mm, 4015mm, 4020mm, or custom sizes). This means you can store more sheets in the same footprint as your old stacking system—without stacking a single sheet. For small to mid-size shops where space is at a premium, this is a game-changer.

The Numbers Don’t Lie: Scratched Metal vs. Herochu Racks

Let’s break down the financial impact of switching to Herochu’s delicate metal racks.

| Cost Category | Traditional Stacking | Herochu Racks | Annual Savings |

| Scrap & Rework | $30,000 | $1,200* | $28,800 |

| Wasted Labor Time | 4,800(40hrsx120/hr) | 600(5hrsx120/hr) | $4,200 |

| Missed Deadlines/Lost Clients | $8,000 | $0 | $8,000 |

| Total Annual Cost | $42,800 | $1,800 | $41,000 |

*Based on occasional minor damage (e.g., accidental tool contact), easily fixed with minimal labor.

With Herochu’s starting price of $4,399, the rack pays for itself in just over 6 weeks. After that, every dollar saved on scrap, labor, and lost clients goes straight to your bottom line. This isn’t an expense—it’s an investment with a rapid ROI.

Who Needs Herochu’s Delicate Metal Racks?

If you work with any high-finish or scratch-sensitive metal, this rack is built for you:

- Custom Metal Fabricators: Creating one-off pieces for architects or luxury clients (where perfection is non-negotiable).

- Aerospace/Automotive Suppliers: Producing precision parts from aluminum or stainless steel (where even small scratches compromise performance).

- Appliance Manufacturers: Building high-end refrigerators or ovens with brushed metal exteriors (where aesthetics drive sales).

- Sign Shops: Working with mirror-finish aluminum for commercial signs (where scratches ruin brand visibility).

- Jewelry/Watchmakers: Storing thin sheets of precious metals (gold, silver) that require ultra-delicate handling.

No matter your niche, if scratches cost you money, Herochu’s racks will save you money.

Why Herochu? Because Your Metals Deserve More Than “Good Enough”

There are plenty of rack manufacturers—but none focus exclusively on protecting delicate metals like Herochu. Here’s what sets us apart:

- Global Certifications: Every rack is CE, UE, and ISO 9001 certified. We don’t just meet safety standards—we exceed them.

- Customization: Need a rack that fits a narrow aisle? A drawer that holds 5-ton sheets? We’ll design it. No two shops are the same, and your rack shouldn’t be either.

- Lifetime Support: From installation (we send a team to set it up correctly) to maintenance (annual check-ups to keep it running smoothly), we’re with you every step of the way.

- Proven Results: Our clients report a 98% reduction in scratched metal within the first month of using our racks. That’s not a promise—it’s a track record.

Invest in Your Profits: Start at $4,399

For a limited time, Herochu’s delicate metal racks start at just $4,399—less than the cost of two months of scratched metal for most shops. And because we know you need to see it to believe it, we offer a 30-day scratch-free guarantee: if you experience any damage due to the rack’s design, we’ll repair or replace the affected material and adjust the rack at no cost.

This isn’t just a rack. It’s a promise: no more sacrificing profits to scratches, no more wasted time on “dig and flip” labor, no more missed deadlines. It’s the solution you’ve been waiting for to protect your most valuable assets.

Ready to stop letting racking ruin your revenue? Contact Herochu today for a free, no-obligation consultation. We’ll assess your workshop, recommend a custom design, and show you exactly how much you could save with our delicate metal racks. Your bottom line will thank you.