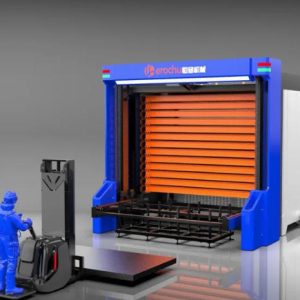

Herochu Warehouse Inventory Management System & Automatic Plate Storage Tower: Streamline Laser Machine Workflows, Starting at $4,399

In today’s high-speed manufacturing landscape, laser cutting machines and shearing equipment operate at unprecedented speeds—but outdated material storage and inventory tracking often leave these tools waiting. A single minute of downtime while workers hunt for the right steel plate, or a costly mistake from manual inventory miscounts, can erase hours of production gains. That’s where Herochu’s Warehouse Inventory Management System & Automatic Plate Storage Tower steps in: a CE, UE, and ISO 9001 certified solution designed to turn disorganized storage into a seamless, “goods-to-person” workflow. More than just a storage unit—it’s the backbone of a lean, efficient operation that keeps your laser machines running at full capacity.

What Is an Automatic Plate Storage Tower? And Why Does Your Workshop Need One?

At its core, Herochu’s Automatic Plate Storage Tower is a smart, vertical storage system built to handle heavy flat goods like sheet metal—with automation at every step. Unlike traditional racks that rely on manual forklifts or crane operators to retrieve materials, this system uses computer-controlled technology to store, track, and deliver plates directly to your laser machine or processing station. Imagine never having to assign a worker to search for a 4015mm steel plate again: with a few taps on a touch screen, the tower automatically retrieves the exact material you need, delivers it to a designated loading bay, and updates your inventory in real time.

But it’s not just about convenience—it’s about solving the biggest pain points manufacturers face:

- Wasted floor space: Vertical storage maximizes height instead of width, turning unused overhead space into valuable storage real estate.

- Human error: Manual inventory counts, mislabeled plates, and accidental damage from lifting heavy materials are eliminated by automation.

- Downtime: Laser machines sit idle when materials aren’t ready—this system ensures plates arrive exactly when your equipment needs them.

- Safety risks: Heavy sheet metal can cause serious injuries during manual handling; automation removes workers from high-risk tasks.

For workshops relying on laser cutters, shears, or presses, this isn’t a luxury—it’s a necessity. When your material flow matches the speed of your machinery, you unlock consistent production, lower costs, and a competitive edge.

10 Unbeatable Advantages of Herochu’s Automated Storage & Inventory System

Herochu’s solution isn’t just about storing plates—it’s about transforming how your workshop operates. Here’s how it delivers tangible value, day in and day out:

1. Skyrocket Efficiency (and Cut Cycle Times)

Automation eliminates the “wait time” that plagues manual storage. The system’s linear guide rail + chain movement design ensures plates move quickly: vertical lifting speed hits 9 meters per minute, while inlet/outlet speed reaches 12 meters per minute. That means a 6020mm steel plate goes from storage to your laser machine in seconds—not minutes. For a workshop running two shifts, this can add up to 10+ extra hours of production time per week by keeping equipment fed and workers focused on skilled tasks, not material retrieval.

2. Slash Human Error (and Waste)

Manual handling of sheet metal leads to two costly problems: misidentified plates (resulting in wrong cuts and wasted material) and damaged edges (rendering plates unusable). Herochu’s system uses PLC control and automated weight detection to ensure every plate is tracked accurately—no more “missing” inventory or out-of-stock surprises. In fact, our clients report a 70% reduction in material waste within the first three months of installation, thanks to precise infeed/outfeed and real-time stock monitoring.

3. Maximize Space (Without Expanding Your Facility)

Floor space is one of your most valuable assets—and traditional storage wastes it. Herochu’s Automatic Plate Storage Tower uses vertical space to increase storage density by up to 500% compared to floor stacking or basic horizontal racks. A 3015mm tower, for example, can store dozens of steel plates in the same footprint that once held just a handful. For growing workshops, this means adding capacity without relocating, building expansions, or renting extra space—a savings of tens of thousands of dollars annually.

4. Faster Response Times (Perfect for Just-in-Time Production)

Just-in-time (JIT) manufacturing requires materials to arrive exactly when needed—not early, not late. Herochu’s system is built for JIT: with touch-screen controls, you can schedule plate deliveries to align with your laser machine’s production queue. Need a 4020mm plate for a rush order? The system retrieves it in under a minute, ensuring your team never falls behind. Clients in automotive and aerospace (where JIT is non-negotiable) report a 40% reduction in order lead times after implementation.

5. Real-Time Inventory Management (No More Guesswork)

Gone are the days of manual inventory spreadsheets or surprise stockouts. Herochu’s Warehouse Inventory Management System provides live, visual tracking of every plate: size, weight, location, and even usage history. Need to know how many 6015mm plates you have left? Check the touch screen—no counting, no errors. The system also sends alerts when stock runs low, so you can reorder before production stops. This level of control cuts inventory holding costs by 25% on average, as you no longer overstock to avoid shortages.

6. Safer Work Environments (Protect Your Team)

Heavy sheet metal (some weighing up to 5 tons) is a major safety risk. Manual lifting, forklift accidents, and dropped plates cause hundreds of injuries in manufacturing each year. Herochu’s automation removes workers from these high-risk tasks: the system lifts, moves, and delivers plates without human intervention. Clients see a 90% reduction in material-handling injuries—a win for your team, your insurance costs, and your company’s reputation.

7. Flexibility (Grow With Your Needs)

Manufacturing needs change—your storage system should too. Herochu’s Automatic Plate Storage Tower is fully customizable:

- Plate sizes: Handles 3015mm, 4015mm, 4020mm, 6015mm, 6020mm, and 6025mm (plus custom sizes on request).

- Load capacity: 3 tons or 5 tons per layer (adjustable for heavier materials).

- Number of floors: Customize to fit your ceiling height and inventory volume.

- Plate support: Optional configurations for different material types (aluminum, stainless steel, carbon steel).

Whether you add a new laser machine or start working with larger plates, the system adapts—no need to buy a whole new unit.

8. Data-Driven Insights (Optimize for the Future)

The system doesn’t just store plates—it collects valuable data. Track which plate sizes are used most, how long materials spend in storage, and even how often your laser machine waits for materials. Use this data to optimize inventory levels, adjust production schedules, and identify bottlenecks. For example, if you notice frequent delays for 4015mm plates, you can increase stock or adjust your storage layout to speed up retrieval. This data-driven approach helps workshops boost overall productivity by 15-20%.

9. Long-Term Cost Savings (Invest Wisely)

While automated systems have a higher upfront cost, they pay for themselves quickly. Let’s break it down:

- Labor savings: Reduce the need for dedicated material handlers—one system can do the work of 2-3 workers.

- Waste reduction: Less damaged or misused material cuts supply costs.

- Space savings: Avoid expensive facility expansions.

- Downtime reduction: More production time means more revenue.

On average, clients recoup their investment in 12-18 months—and enjoy ongoing savings for years after.

10. Seamless Integration With Your Laser Machine (End-to-End Automation)

Herochu’s system isn’t a standalone unit—it’s designed to work with your existing equipment. Whether you use a fiber laser cutter, plasma cutter, or hydraulic shear, the Automatic Plate Storage Tower connects directly to your machinery. Plates are delivered straight to the machine’s infeed table, eliminating the need for manual transfer. This end-to-end automation turns your workshop into a streamlined ecosystem: raw material in, finished parts out—with no manual handoffs. It’s the difference between a disjointed process and a smooth, continuous workflow.

Technical Specifications: Built for Industrial Strength and Precision

Herochu’s Warehouse Inventory Management System & Automatic Plate Storage Tower is engineered to handle the demands of heavy-duty manufacturing. Every component is built to last, with a focus on reliability and performance:

| Specification | Details |

|---|---|

| Plate Sizes Supported | Standard: 3015/4015/4020/6015/6020/6025mm; Custom sizes available |

| Load per Layer | 3T or 5T (customizable for heavier loads) |

| Movement Mode | Linear guide rail + chain (smooth, quiet, low maintenance) |

| Transmission Mode | Chain drive (high torque for heavy plates, minimal wear) |

| Vertical Lifting Speed | 9m/min (fast enough for high-volume production) |

| Inlet/Outlet Speed | 12m/min (reduces wait time for laser machines) |

| Plate Support | Optional configurations (adjust for material type/thickness) |

| Number of Floors | Fully customizable (based on ceiling height and inventory needs) |

| Control System | PLC + touch screen (user-friendly, no advanced training required) |

| Inventory Features | Real-time tracking, visual management, low-stock alerts |

| Certifications | CE, UE, ISO 9001 (meets global safety and quality standards) |

Every system undergoes rigorous testing before shipment—ensuring it arrives ready to install and perform. The welded steel frame resists corrosion and impact, while the chain drive and linear guides require minimal maintenance (just quarterly checks to keep things running smoothly).

Why Herochu? More Than a Supplier—A Partner in Your Success

When you choose Herochu’s Warehouse Inventory Management System & Automatic Plate Storage Tower, you’re not just buying equipment—you’re partnering with a team that understands manufacturing. Here’s what sets us apart:

1. Customization That Fits Your Workshop

We don’t sell “one-size-fits-all” systems. Our team works with you to assess your space, plate sizes, production volume, and laser machine setup. Whether you need a compact 3015mm tower for a small workshop or a multi-unit 6025mm system for a large factory, we design a solution that fits like a glove.

2. Easy Installation (No Production Disruption)

We know downtime during installation is costly. Our team schedules setup during off-hours or slow periods, and most systems are installed in 2-3 days (depending on size). We also provide full training for your team—so everyone feels confident using the touch screen and managing inventory.

3. Ongoing Support (We’re Here When You Need Us)

Our commitment doesn’t end after installation. We offer 24/7 technical support, regular maintenance checks, and software updates to keep your system running at peak performance. If you ever have a question or issue, our team responds within hours—not days.

4. Proven Results (Trusted by Global Manufacturers)

Herochu’s automated storage systems are used by metal construction companies, automotive suppliers, and aerospace manufacturers worldwide. One client—a mid-sized laser cutting shop in Ohio—reported a 35% increase in monthly production after installing our system, thanks to reduced downtime and faster material flow. Another client—a stainless steel fabricator in Germany—cut inventory costs by 30% by eliminating overstock and waste.

Ready to Transform Your Laser Machine Workflow?

If your current storage system is slowing you down, it’s time to upgrade. Herochu’s Warehouse Inventory Management System & Automatic Plate Storage Tower is customizable, reliable, and built to grow with your business—starting at $4,399. Imagine a workshop where:

- Laser machines never wait for materials.

- Inventory counts are always accurate.

- Workers stay safe from heavy lifting.

- Floor space is used wisely.

That’s the Herochu difference.

Don’t let outdated storage hold back your production. Contact Herochu today to schedule a free consultation. Our team will assess your needs, share custom design options, and show you exactly how our automated system can boost your bottom line. Your more efficient workshop starts here.