Herochu Engineered Storage Racks: Secure, Accessible Storage for Elevator Components

In elevator manufacturing, precision isn’t just a buzzword—it’s the difference between a flawless final product and costly rework. Every component, from mirror-finish stainless steel cabin panels to heavy structural frames, demands care. But for too many fabricators, a hidden bottleneck undermines this precision: disorganized storage. Stacking delicate panels, fumbling to “dig and flip” for parts, and watching expensive machinery sit idle while teams hunt for materials—this isn’t just inefficient. It’s a threat to your bottom line.

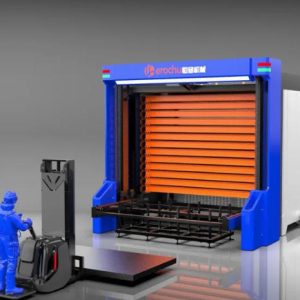

Herochu’s Engineered Storage Racks for Elevator Parts solve this problem at its root. Built exclusively for the unique needs of elevator component fabrication, this system delivers 100% selectivity, zero-friction handling, and heavy-duty durability—all while being customizable to your workshop, CE/UE/ISO 9001 certified, and starting at just $4,399. It’s not just storage; it’s a way to protect your high-value parts, speed up production, and elevate your entire operation.

The Hidden Cost of “Good Enough” Storage for Elevator Parts

Elevator components are unlike any other manufacturing material. They’re often large (think 8ft stainless steel cabin panels), heavy (structural frames can weigh 2+ tons), and ultra-delicate (a single scratch on a mirror-finish surface renders it useless). Traditional storage—stacking these parts on pallets, leaning them against walls, or shoving them into fixed shelves—creates a cascade of problems that eat into your profits:

1. Material Waste: Scratches That Cost Thousands

2. Machine Downtime: Idle Equipment = Lost Revenue

Your laser cutter, press brake, and CNC machine are your most valuable assets—so why let them sit idle? With traditional storage, operators spend 30–60 minutes per job digging through stacks to find the right panel or frame. For a shop running 10 jobs a week, that’s 50+ hours of wasted machine time monthly.

3. Labor Inefficiency: Teams Trapped in “Dig and Flip” Cycles

“Dig and flip” isn’t just time-consuming—it’s physically demanding. Two or three operators struggle to move 2-ton structural frames out of the way to reach a smaller panel, risking back strains, dropped parts, and workplace injuries. The Bureau of Labor Statistics reports that material handling accidents cost manufacturers $1.4 billion annually in workers’ compensation claims. For elevator fabricators, this risk is even higher—heavy, awkwardly shaped parts are prime candidates for accidents.

4. Missed Deadlines: When Storage Delays Cost You Clients

Elevator projects run on tight timelines. A single delayed component (thanks to lost parts or rework) can hold up an entire installation—annoying general contractors and putting future projects at risk. In an industry where referrals drive 60% of new business, a missed deadline can cost you more than just a fee; it can cost you long-term partnerships.

These aren’t just “inconveniences”—they’re systemic issues caused by storage that wasn’t built for elevator parts. Herochu’s engineered racks eliminate every one of them.

What Makes Herochu’s Racks the “Precision Storage” Solution for Elevator Parts?

Precision storage isn’t just about “being organized”—it’s about designing a system that adapts to the unique challenges of elevator components. Herochu’s racks do this with three core features: 100% extendable drawers, zero-friction handling, and seamless workflow integration. Here’s how it works:

1. 100% Extendable Drawers: Access Any Part in Seconds

The heart of Herochu’s system is its heavy-duty, fully extendable drawers—built from high-strength Q235 structural steel (the same material used in elevator shafts) to handle loads up to 4.5 tons (10,000 lbs). Unlike fixed shelves or stacks, these drawers roll completely out of the rack frame, giving you unobstructed overhead access to every part.

- No More “Dig and Flip”: Need a 6ft brushed aluminum cabin panel? Extend the drawer, lower your vacuum lifter, and lift the panel vertically—no moving other parts, no scraping against adjacent panels. Retrieval time drops from 30–60 minutes to under 5 minutes.

- Labeled, Organized SKUs: Each drawer can be labeled by component type (e.g., “Mirror-Finish Cabin Panels, 8ft x 4ft” or “Structural Frame, 2-Ton”), so operators know exactly where to find what they need. No more hunting through unmarked stacks.

- Customizable Sizes: Elevator parts come in all shapes and sizes—and your rack should too. Choose from standard drawer widths (3015mm, 4015mm, 4020mm) or customize to fit extra-large components (like 10ft cabin side panels). Adjust the number of layers (3+1, 4+1, or custom) to match your ceiling height and inventory volume.

For example, a fabricator specializing in luxury elevator cabins can use a 4+1 layer rack to store:

- Layer 1: Small decorative trim pieces (lightweight, easy access).

- Layer 2: 4ft x 4ft mirror-finish panels (protected from scratches).

- Layer 3: 8ft x 4ft brushed aluminum side panels (heavy-duty drawer supports).

- Layer 4: Structural brackets (forklift-accessible for quick transport to assembly).

Every part has a dedicated space—no more chaos, no more waste.

2. Zero-Friction Handling: Protect Delicate Surfaces

Elevator components like mirror-finish stainless steel or laminated cabin panels are scratch magnets. Even a tiny scuff from a rough shelf or adjacent panel can ruin them. Herochu’s racks eliminate this risk with zero-friction handling:

- Vertical Lifting Only: Parts are lifted straight up by a crane or vacuum lifter—never dragged, slid, or stacked. This means no contact with other materials, no edge dents, and no surface scratches.

- Soft-Contact Drawer Liners: Optional non-abrasive liners line the inside of each drawer, providing an extra buffer against accidental bumps. These liners are resistant to oils, solvents, and moisture (common in fabrication shops) and won’t leave residue on delicate surfaces.

- Controlled Movement: For heavy parts (like 4.5-ton structural frames), the rack’s manual crank or automated PLC system ensures smooth, slow drawer extension. No jerky movements that could shift parts and cause damage.

The result? A near-zero damage rate. Herochu clients report a 98% reduction in scratched or dented elevator components within the first month of using the racks. That’s $20,000+ saved annually in scrap and rework—money that goes straight to your bottom line.

3. Workflow Integration: From Rack to Machine, Seamlessly

Elevator fabrication is a linear process: cut → bend → assemble. Your storage should support this flow—not interrupt it. Herochu’s racks are designed to integrate directly into your production line with forklift-accessible drawers:

- Drawer-as-a-Pallet: Each drawer acts as a mobile storage unit. An operator can use a forklift to lift the entire drawer (with parts safely secured inside) and transport it directly to your laser cutter or press brake. No more unloading parts from the rack, loading them onto a pallet, and unloading again at the machine.

- Lean Manufacturing Ready: This “rack-to-machine” process eliminates unnecessary handling steps—core to lean manufacturing principles. It cuts production time per job by 20–30% and reduces the risk of damage during transport.

- Space-Saving Design: Forklift-accessible drawers mean you don’t need extra space for pallets or staging areas. The rack itself becomes your staging area, freeing up 10–15% of your workshop floor space for additional machinery or assembly stations.

For a fabricator handling 50 elevator cabin orders a month, this integration translates to 10–15 more completed orders annually—all from optimizing storage.

Technical Specifications: Built for Elevator Parts’ Unique Needs

Herochu’s racks aren’t just “strong”—they’re engineered to handle the specific weights and sizes of elevator components. Here’s how the standard and customizable options stack up:

| Feature | Standard Options | Customizable Options |

| Drawer Load Capacity | 2tons, 3tons, 4.5tons | Up to 6tons per drawer |

| Drawer Sizes | 3015mm x 1500mm, 4015mm x 1500mm, 4020mm x 2000mm | Any size (e.g., 6000mm x 2000mm for extra-large panels) |

| Number of Layers | 3+1, 4+1 | Up to 6+1 layers (based on ceiling height) |

| Operation System | Manual crank (2–3ton loads), PLC frequency conversion control (4.5–6ton loads) | Automated PLC with WMS integration (for inventory tracking) |

| Finish | Powder-coated epoxy (Orange/Blue) | Custom colors (e.g., white for cleanroom environments) |

| Certifications | CE, UE, ISO 9001 | Additional certifications (e.g., OSHA for US markets) |

Every component is tested to withstand the rigors of elevator fabrication—from daily forklift use to heavy load cycles. This isn’t a “one-size-fits-all” rack; it’s a purpose-built solution for your industry.

Who Benefits Most from Herochu’s Elevator Parts Storage Racks?

This system is tailored to any operation that manufactures or assembles elevator components:

- Elevator Cabin Fabricators: Protect mirror-finish and brushed metal panels from scratches, with quick access for custom orders.

- Structural Component Manufacturers: Store heavy frames and brackets safely, with forklift access to speed up assembly.

- Elevator Assembly Shops: Keep small parts (trim, hardware, glass supports) organized, reducing search time for final installation.

- Custom Elevator Designers: Handle unique, one-off components (e.g., curved stainless steel panels) without risking damage.

- Large-Scale Manufacturers: Scale storage with customizable layers and drawer sizes to match high-volume production.

No matter your niche, if elevator parts are central to your business, Herochu’s racks will transform how you store and use them.

The Numbers: Precision Storage vs. Traditional Stacking

Let’s quantify the impact of switching to Herochu’s racks for a mid-size elevator fabricator (20 employees, 50 cabin orders/month):

| Metric | Traditional Storage | Herochu Precision Storage | Annual Impact |

| Component Retrieval Time | 45 minutes/job | 5 minutes/job | 3,333 hours saved (≈ $500,000 in machine uptime) |

| Material Damage Rate | 8% (4 scratched parts/month) | 0.2% (0.1 parts/month) | $23,400 saved in scrap/rework |

| Labor Requirements | 2 operators/retrieval | 1 operator/retrieval | $39,000 saved in labor costs |

| Floor Space Usage | 500 sq ft for storage + staging | 350 sq ft for storage (no staging) | 150 sq ft freed for new machinery |

With a starting price of $4,399, the rack pays for itself in just 3 weeks. After that, every dollar saved goes straight to your profit margin. This isn’t an expense—it’s the most cost-effective investment you can make in your elevator fabrication business.

Why Choose Herochu? Because Elevator Parts Deserve Specialized Storage

There are plenty of storage rack manufacturers—but none understand elevator fabrication like Herochu. Here’s what sets us apart:

- Industry Expertise: We’ve worked with 50+ elevator fabricators to refine our racks, so we know exactly what you need (e.g., soft liners for mirror panels, heavy-duty drawers for frames).

- Customization Without Delays: Standard racks ship in 2–3 weeks; custom designs take just 4–6 weeks (half the industry average).

- Lifetime Support: Our team provides on-site installation, operator training, and annual maintenance checks—so your rack runs smoothly for decades.

- Guaranteed Results: We offer a 60-day “Zero Damage Guarantee”: if you experience a scratch or dent due to rack design, we’ll cover the cost of the damaged part and adjust the rack for free.

Invest in Precision: Start at $4,399

For a limited time, Herochu’s Engineered Storage Racks for Elevator Parts start at just $4,399—less than the cost of one scratched elevator cabin panel. And for custom orders, we offer a free workshop assessment: our team will visit your facility, measure your space, and design a rack that fits your exact component sizes and workflow.

Don’t let outdated storage hold back your elevator fabrication business. Herochu’s racks protect your parts, speed up production, and boost your profits—all while keeping your team safe.

Ready to elevate your storage? Contact Herochu today for a free consultation. We’ll show you how precision storage can transform your operation—one flawless elevator component at a time.