Is Your Sheet Metal Storage Costing You Time? Here’s the Fix

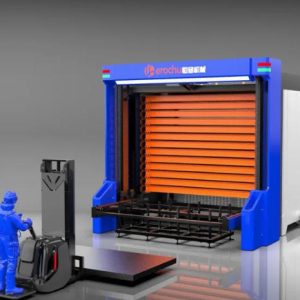

Herochu heavy-duty drawer racks – tailor-made for your bay, from $2 999, CE/ISO 9001 – turn the clock-eating clutter beside your laser into a five-second, one-hand operation.

The hidden invoice

Every morning the same drama plays out: the nest is ready, the laser is humming, but the 4 mm stainless is somewhere near the back wall, third stack from the left, under last week’s rusty off-cuts. Twenty minutes later the forklift finally appears, pallet tips, sheets slide, edges kiss the concrete and another perfectly good part shows up in downstream with mysterious dents. You have just paid four machine cycles, two operators and a shot of adrenaline for the privilege of moving steel you already own. Over a year that improvisation adds up to more hours than a full-time employee – except it produces nothing except scrap and overtime.

Floor space is rent, not scenery

A 4 × 2 m plate occupies 8 m² flat; stack ten high and you still surrender 8 m² because you can’t use the air above. Herochu’s HC-B rack stores the same tonnage vertically, inside a 2 m² shadow. The maths is brutal: at €60/m² industrial rent a single rack frees up 48 m², enough cash to lease a second laser or simply stop paying for the annex you thought you needed. Customers regularly report reclaiming 70-80 % of their raw-material footprint without pouring a single cubic metre of concrete.

The safety line you keep crossing

Manual sheet handling is still the top cause of lost-time injuries in fab shops. A 3 mm plate looks harmless until the wind catches it like a sail and 40 kg of razor-thin guillotine drops on a boot. The HC-B drawer removes the circus: one person pulls a handle, the tray rolls out on sealed bearings and stops at knee height. A vacuum lifter or magnetic hook does the rest; no one climbs, no one leans, no one yells “look out below.” Insurance underwriters love the incident graph after install – some UK fabricators saw premiums drop 12 % the following renewal.

Built like a freight car, finished like a toolbox

The spine is a single 8 mm laser-cut side wall, plug-welded to 100 × 100 × 5 mm square tube uprights. After shot-blasting we bake on TGIC-free polyester powder at 200 °C; you can pressure-wash it, weld next to it, or let salty road dust blow through the loading dock for a decade without blush. Load rails are induction-hardened to 55 HRC so a 5 t coil sheet can ride in and out thirty thousand times before we even speak about wear strips. Optional hot-dip galvanising pushes corrosion resistance to coastal or offshore standards.

Sizes that start big and grow

HC-B3015-63 cradles 3 × 1.5 m plates, six levels, 3 t per shelf – the sweet spot for job shops running 3015 fibre lasers. Step up to HC-B4020-65 and you get 4 × 2 m sheets, 5 t per drawer, still inside a 2 m aisle width. Need 6 m long façade panels? HC-B6020-66 keeps them flat, level, and reachable in under a minute. Every dimension – height, shelf pitch, handle side – is editable. We have shipped 14 m tall towers through a 3 m roller door by splitting the frame; bolt it back together and tolerances stay within 0.5 mm.

The drawer that thinks like a tray

Each cassette is a 60 mm deep pan with replaceable PE strips so plates never scrape steel on steel. Divider slots every 100 mm let you segregate 2 mm from 20 mm without mixed nesting nightmares. A hidden cam latch auto-locks when the drawer closes; tug the handle again and it releases, even with 5 t aboard. Fork pockets underneath mean you can pull a full cassette and drop it on a truck, returning it empty later – the birth of a returnable supply loop that slashes packaging waste and supplier handling.

From chaos to five-second choreography

Imagine this: operator scans the job barcode, ERP spits “5 pcs 3 mm ALU 2500 × 1250,” tower indicator lights the third drawer. Operator walks three metres, pulls handle, vacuum lifter sucks the top sheet, tray rolls home. Elapsed time: 28 seconds. Your laser meanwhile never left the “beam on” state. Multiply by twenty change-overs a day across three machines and you have bought an extra laser hour daily without adding a shift.

Accessories that finish the story

- Mobile base: bolt the whole rack on heavy-duty casters and gain flexibility for cellular manufacturing.

- Crane interface: fold-down side wings let an overhead magnet land sheets without door clearance.

- RFID kit: each cassette carries a tag; the PLC logs who took what, when, and how much is left.

- Rubber top cap: converts the rack into a temporary workbench for inspection or deburring.

Price that respects cashflow

Entry unit HC-B3015-63 starts at $2 999 ex-works, including five drawers, assembly kit, and CE documentation. A comparable block of floor space plus two pallets, banding, and the invisible cost of hunting will run past that figure in six months. Lease it, depreciate it over ten years, or write it off as a safety capital project – the accountant always smiles because the rack outlives the tax schedule.

Ten-year promise, two-hour reply

We weld, blast, and powder-coat in one facility, so every serial number is traceable to steel coil and chemical bath. Structural warranty is ten years; wear parts (bearings, handles) ship inside 48 hours from regional hubs. Send a photo of a dented upright and we airfreight a laser-cut replacement panel pre-painted, no questions, no invoice. That is why the same customers come back for bay two, three and four – the rack is still there, still square, still opening like new.

Stop renting chaos

Every minute your machines wait for material you are paying depreciation on idle iron. Every scuffed sheet, every near-miss, every square metre lost to clutter is margin walking out the door. Bolt down a Herochu drawer rack this weekend and Monday morning the laser eats the moment the nest is released. That is not storage – that is time travel at steel speed.