Herochu High-Performance Sheet Metal Racking: Transform Storage into a Lean Manufacturing Driver, Starting at $2,999

For fabricators drowning in disorganized sheet metal piles, storage isn’t just a logistical hassle—it’s a silent profit killer. A multi-million dollar laser cutter idling for 30 minutes while operators hunt for a single steel sheet. Valuable floor space eaten up by horizontal stacks, leaving no room for new production equipment. Scratched or dented materials from endless “stack-shuffling” that turns good stock into scrap. These aren’t just minor inconveniences—they’re “Muda,” the Japanese term for waste that cripples lean manufacturing goals.

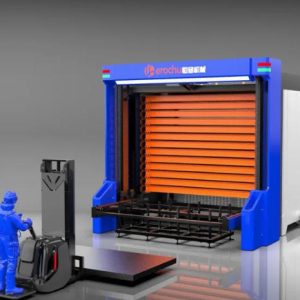

Herochu’s High-Performance Sheet Metal Racking changes this narrative. CE, UE, and ISO 9001 certified, this isn’t just a place to store metal—it’s an integrated productivity system that turns passive storage into an active driver of efficiency. Starting at $2,999 and fully customizable to your workshop’s layout, it eliminates waste, reclaims space, and keeps your most expensive machinery running at full capacity. For progressive fabricators, it’s the difference between fighting to keep up and leading the pack.

Why Traditional Sheet Metal Storage Is a Lean Manufacturing Nightmare

Ask any production manager about their storage woes, and you’ll hear the same frustrations—all rooted in waste that traditional methods can’t solve:

1. Waste of Waiting: Your Most Expensive Machines Sit Idle

A laser cutter or punch press costs thousands of dollars per hour to operate. When it’s sitting idle because an operator is digging through a stack of sheet metal to find the right gauge or size, you’re bleeding money. Traditional storage turns “retrieval time” into a guessing game: 30 minutes here, 20 minutes there, adding up to 4-6 hours of lost production per week for a single machine. For shops running two shifts, that’s over 250 hours of wasted capacity annually—enough to complete dozens of extra orders.

2. Waste of Motion & Defects: Stack-Shuffling Destroys Time and Materials

Retrieving a single sheet from the bottom of a horizontal stack isn’t just slow—it’s dangerous and destructive. It often requires two or three workers, a forklift, and moving 5-6 pallets out of the way just to reach the one you need. Every shuffle risks scratches, dents, or bent edges—turning a $500 sheet of stainless steel into scrap. Even if the material survives, the time spent moving and re-stacking adds up: a single retrieval can take 15 minutes of labor that could be spent on value-added tasks like cutting or finishing.

3. Waste of Space: Horizontal Stacks Steal Room for Growth

Floor space is your workshop’s most valuable real estate. Traditional horizontal storage eats it up: a single stack of 4000x1500mm sheets can take up 100+ square feet of floor space. For a mid-sized fabricator, that’s enough room for a new welding station, a quality control area, or even a second laser cutter—tools that would actually grow your business. Instead, that space is wasted on passive storage, forcing you to choose between expanding your facility (and your rent) or turning down new orders.

Herochu’s High-Performance Sheet Metal Racking attacks all three wastes head-on. It doesn’t just store your material—it reorganizes your entire workflow around efficiency.

The Lean-Driven Features That Transform Your Workshop

Herochu’s racking system is designed with one goal in mind: to make lean manufacturing actionable. Every feature is built to eliminate waste, speed up workflows, and keep your team safe—turning storage from a cost center into a profit driver.

1. 100% Selectivity: No More Stack-Shuffling—Access Any Sheet in Minutes

The single most impactful feature of this system is its 100% selectivity. Unlike traditional stacks where the sheet you need is buried under others, every drawer or pallet in Herochu’s racking rolls out completely—giving you immediate access to any sheet, any time. Need a 1250x1250mm aluminum sheet for a rush order? Pull the drawer out, grab it, and get it to the laser cutter in under 5 minutes. No moving other pallets, no guessing where it’s hidden, no wasting time.

This isn’t just convenience—it’s a workflow revolution. For David, a production manager at a U.S. fabrication shop, this change alone cut retrieval time from “45 minutes on a bad day” to a consistent 5 minutes. “Our laser cutters used to wait an hour a day for material,” he said. “Now they’re running non-stop. We added 15% to our monthly output just from eliminating that downtime.”

2. One-Person, Safe Operation: Cut Labor Costs and Injury Risks

Lean manufacturing isn’t just about efficiency—it’s about safety. Traditional sheet metal retrieval is a high-risk, labor-heavy task: multiple workers, heavy equipment, and tight spaces create the perfect conditions for accidents. Herochu’s racking reimagines this process as a safe, one-person operation.

For loads up to 5,000 lbs, a simple manual hand-crank lets one operator roll out drawers with minimal effort. For heavier loads, the system integrates seamlessly with forklifts—no need for extra hands. This not only cuts labor costs (replacing 2-3 workers per shift with a single operator) but also slashes injury risks. David’s shop saw a immediate drop in near-misses after installation: “We had a close call with a slipping pallet before the racks. Now, there’s no more stacking high or reaching over piles. Our operators feel safer, and that makes them more productive.”

3. High-Density Vertical Storage: Reclaim 80% of Your Floor Space

The biggest waste in most workshops is unused vertical space. Herochu’s racking turns that wasted height into valuable storage, with a vertical, high-density design that reclaims up to 80% of the floor space used by horizontal stacks. A rack that holds 50 sheets of 4000x1500mm steel might take up just 20 square feet—compared to 100+ square feet for a traditional stack.

What does that reclaimed space look like for your shop? It could be a new press brake that lets you take on more complex orders. It could be a dedicated quality control area that reduces defects. Or it could be extra room for material staging that speeds up production. For David’s team, it was a new welding station: “We went from a cluttered shop where we could barely move to having space for a second welding team. That’s another stream of revenue we wouldn’t have had without the racks.”

4. Visual Inventory Management: Eliminate Overstock and Stockouts

Lean manufacturing relies on visibility—and traditional storage hides your inventory behind stacks of metal. Herochu’s racking turns your stock into a visual management tool. Every drawer is labeled clearly, and because sheets are stored vertically (not stacked), a quick glance tells you exactly how much of each size, gauge, and material you have.

This eliminates two costly problems: overstocking (buying more material than you need because you can’t see what’s on hand) and stockouts (running out of critical sheets because you didn’t notice supplies were low). David’s shop cut inventory costs by 20%: “We used to order extra sheets ‘just in case’ because we couldn’t find what we had. Now we know exactly what’s in stock. We’re not tying up cash in excess material anymore.”

Customizable to Your Lean Layout: No Two Shops Are the Same

Lean manufacturing works best when tools fit your unique workflow—not the other way around. Herochu’s High-Performance Sheet Metal Racking is fully customizable to your workshop’s size, material needs, and production goals. Whether you’re a small shop with 500 square feet of floor space or a large fabricator with multiple production lines, we’ll design a system that fits:

Material Compatibility: Handle Any Sheet, Any Size

Herochu’s racks work with the materials you use every day:

- Sheet metal (steel, aluminum, stainless steel, carbon steel)

- Thicknesses from 1mm to 20mm (customizable for thicker materials)

- Sizes from 1250x1250mm to 6000x2000mm (and beyond, with custom designs)

Whether you’re storing thin aluminum sheets for automotive parts or thick steel plates for industrial machinery, the system adapts to your needs.

Layout Flexibility: Fit Your Space, Not the Other Way Around

We don’t force you to rearrange your shop for the racks—we design the racks for your shop. Need a system that fits along a narrow wall? We’ll build a slim, vertical rack. Need multiple racks near your laser cutters for quick staging? We’ll create a modular setup that lets you add more units as you grow. Even odd-shaped spaces (like corners or areas around existing machinery) are no problem—our team will measure your space and design a solution that maximizes every inch.

Load Capacity: Match Your Heavy-Duty Needs

Not all sheet metal is the same—some shops handle 300KG sheets, others 1000KG+. Herochu’s racks are built to match your load requirements, with standard capacities up to 5,000 lbs per drawer (and custom options for heavier loads). Every rack is engineered with a sturdy welded steel frame and reinforced drawers, ensuring it can handle the weight of your materials day in and day out—no bending, no sagging, no risk of failure.

Why Herochu’s Racking Is a Lean Investment (Not Just a Cost)

At first glance, investing in a sheet metal racking system might seem like an expense. But for lean-focused fabricators, it’s one of the most profitable investments you can make—with a clear return on investment (ROI) that shows up in months, not years. Here’s how:

1. Increased Machine Uptime = More Revenue

Every minute your laser cutter or punch press is running, it’s making you money. Herochu’s racks eliminate the downtime caused by slow material retrieval.

2. Reduced Material Waste = Lower Costs

Traditional storage destroys materials: scratches, dents, and bent edges turn good stock into scrap. Herochu’s racks protect your sheets with smooth-rolling drawers and secure storage, cutting material waste by 30% or more.

3. Reclaimed Space = Growth Without Expansion

Expanding your workshop means higher rent, construction costs, and downtime. Herochu’s racks let you grow without moving: the 80% of floor space you reclaim can be used for new equipment, more workers, or additional production lines. David’s shop added a new welding station that generates $2,000 per week in extra revenue—all from space they already had.

4. Lower Labor Costs = Fewer Expenses, More Profit

Why Choose Herochu? Lean Manufacturing Experts, Not Just Racking Suppliers

When you buy Herochu’s High-Performance Sheet Metal Racking, you’re not just buying storage—you’re partnering with a team that understands lean manufacturing. We don’t just sell racks; we help you build a more efficient workshop. Here’s what sets us apart:

1. Quality You Can Trust: CE, UE, ISO 9001 Certified

Every Herochu rack is built to last, with components tested to meet global safety and quality standards. The welded steel frame resists corrosion and impact, even in harsh workshop environments. The rolling drawers use heavy-duty bearings that handle thousands of cycles without wear. This isn’t a “quick fix” rack—it’s a long-term investment that will serve your shop for decades.

2. Lean-Focused Design: Built by Fabricators, for Fabricators

Our team includes former fabricators who know the pain of disorganized storage firsthand. We didn’t design these racks in a lab—we designed them based on real-world workflow challenges. Every feature (from 100% selectivity to vertical storage) is rooted in solving the wastes that fabricators face daily.

3. Easy Installation: No Downtime, No Headaches

We know you can’t afford to stop production for installation. Our team works around your schedule—often installing racks during off-hours or slow periods—to minimize disruption. Most systems are up and running in 1-2 days, and we provide full training for your team so everyone knows how to use the racks safely and efficiently.

4. Ongoing Support: We’re With You for the Long Haul

Our commitment doesn’t end when the racks are installed. We offer 24/7 technical support, regular maintenance checks, and replacement parts with fast shipping. If you need to expand your system as your shop grows, we’ll help you design and install additional racks that integrate seamlessly with your existing setup.

Ready to Turn Storage Into a Lean Manufacturing Driver?

If your workshop is drowning in waste—idle machines, damaged materials, wasted space—it’s time to invest in a system that solves these problems at the source. Herochu’s High-Performance Sheet Metal Racking is customizable, affordable (starting at $2,999), and built to turn your storage into a lean manufacturing asset.

Imagine a workshop where:

- Your laser cutters run non-stop, no more waiting for material.

- Your operators work safely, with no more stack-shuffling or heavy lifting.

- You have 80% more floor space to grow your business.

- Your inventory is visible, so you never overstock or run out of critical sheets.

That’s the lean layout Herochu delivers.

Don’t let traditional storage hold back your lean goals. Contact Herochu today to schedule a free consultation. Our team will assess your workshop, understand your workflow, and design a racking system that fits your needs—and your budget. Your more efficient, profitable shop starts here.