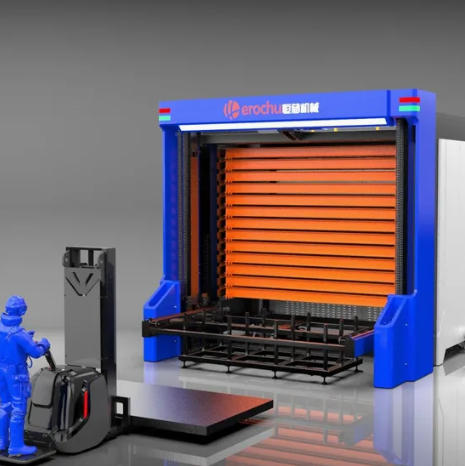

Automated Plate Warehouse with High Load Capacity

For manufacturers, fabricators, and industrial operations struggling with disorganized sheet metal storage, inefficient retrieval, and wasted floor space, the Herochu Automated Plate Warehouse isn’t just a storage unit—it’s a productivity game-changer. Designed to centralize, secure, and streamline every step of sheet metal management, this system eliminates manual errors, cuts labor costs, and protects your valuable materials—all while adhering to global safety standards (CE, UE, ISO 9001 certified). Starting at just $8,999, it’s a scalable investment that grows with your workshop’s unique needs.

Herochu Automated Plate Warehouse: The Ultimate High Load Capacity Solution for Sheet Metal Storage

For manufacturers, fabricators, and industrial operations struggling with disorganized sheet metal storage, inefficient retrieval, and wasted floor space, the Herochu Automated Plate Warehouse isn’t just a storage unit—it’s a productivity game-changer. Designed to centralize, secure, and streamline every step of sheet metal management, this system eliminates manual errors, cuts labor costs, and protects your valuable materials—all while adhering to global safety standards (CE, UE, ISO 9001 certified). Starting at just $8,999, it’s a scalable investment that grows with your workshop’s unique needs.

Why Herochu’s Automated Plate Warehouse Stands Out for Industrial Teams

Traditional sheet metal storage—whether stacked pallets, static racks, or disorganized bins—comes with hidden costs: lost time searching for specific sheets, damaged materials from improper handling, and wasted labor hours on manual loading/unloading. Herochu’s solution addresses all these pain points with smart automation, heavy-duty construction, and intuitive design. Here’s how it transforms your workflow:

1. High Load Capacity That Handles Your Heaviest Materials

No more compromising on storage due to weight limits. The Herochu Automated Plate Warehouse is engineered for industrial strength, with 3T or 5T load capacity per layer (choose based on your needs). Whether you’re storing thick steel sheets, dense aluminum plates, or corrosion-resistant stainless steel, this system supports even your heaviest materials without strain. Unlike flimsy generic racks that risk bending or collapsing, Herochu’s frame is built to last—ensuring long-term reliability for high-volume operations.

Available in six standard sizes to fit your workshop’s footprint: 3015mm, 4015mm, 4020mm, 6015mm, 6020mm, and 6025mm. Need something larger or more compact? We offer full customization for dimensions, number of floors, and number of storage units—so you never have to force your workflow around a one-size-fits-all solution.

2. 100% Automated Storage & Retrieval: Speed, Accuracy, and Safety

Forget manual counting, guesswork, or heavy lifting. This system automates every critical step of sheet metal management:

- Centralized Storage: Consolidate all your sheets in one secure location, reducing clutter and freeing up floor space for production.

- Automatic Weight Detection: Eliminates manual weighing errors—each sheet’s weight is logged instantly, ensuring accurate inventory tracking.

- Auto Warehousing & Retrieval: When you need a specific sheet, the system retrieves it automatically—no more sending teams to dig through stacks.

- PLC & Touch Screen Control: Operate the entire system with a user-friendly touch screen, powered by a reliable PLC (Programmable Logic Controller). This ensures consistent, error-free performance, even for team members with minimal training.

The result? Classified visual management of your inventory—you’ll always know exactly where each sheet is, how many you have, and when to reorder. This transparency doesn’t just save time; it prevents costly stockouts and overstocking, keeping your production line running smoothly.

3. Horizontal Storage with 100% Extendable Drawers: Direct Access, No Hassle

One of the biggest frustrations with traditional racking is inaccessible sheets—hidden behind others, requiring you to move multiple materials just to reach one. Herochu solves this with 100% extendable roll-out drawers (equipped with smooth-rolling wheels) that pull fully outside the rack. Every sheet is visible and accessible in seconds: simply open the rack doors, pull out the desired drawer, and load/unload—no shifting, no lifting, no wasted effort.

This horizontal storage design is ideal for all sheet metal types: steel, aluminum, stainless steel, galvanized sheets, and more. Even long sheets (up to 144 inches in length) fit easily, thanks to the system’s adjustable width options. Whether you’re working with small batches or high-volume orders, this design ensures every sheet is ready when you need it.

4. Labor Savings: 1 Person, Zero Heavy Lifting

Manual sheet metal handling is time-consuming, physically demanding, and risky (think strains, drops, or material damage). Herochu’s Automated Plate Warehouse cuts labor needs drastically—only 1 person is required to operate the entire system, and no heavy lifting is necessary.

The system integrates seamlessly with your existing equipment: pair it with a crane, jib crane, transporter bridge, or vacuum lifter to move sheets effortlessly from the rack to your production line. No more coordinating teams to lift or shift materials—one operator can manage storage, retrieval, and transport in a fraction of the time. Over time, this translates to lower labor costs, fewer workplace injuries, and happier, more productive teams.

5. Compact, Secure Storage That Protects Your Materials

Space is a premium in most workshops—and Herochu’s design maximizes every inch. The system’s vertical and horizontal layout keeps sheets organized without taking up excess floor space, while the durable metal construction shields your materials from dust, moisture, and accidental damage. Unlike open-air storage, which can lead to rust, scratches, or warping, this enclosed rack ensures your sheets stay in pristine condition—preserving product quality and reducing waste.

Safety is built into every detail: the PLC control system prevents overloading, the sturdy frame minimizes tip risks, and the enclosed design keeps unauthorized personnel from accessing sensitive materials. For operations that prioritize compliance (e.g., ISO 9001), this system checks all the boxes—ensuring your storage practices meet global quality and safety standards.

Who Benefits from Herochu’s Automated Plate Warehouse?

This system isn’t just for large factories—it’s tailored to any operation that works with sheet metal:

- Metal Fabricators: Streamline storage for steel, aluminum, or stainless steel sheets used in custom projects.

- Automotive Suppliers: Keep high-volume metal components organized and ready for assembly lines.

- Construction Companies: Store galvanized or corrugated sheets safely on job sites or in warehouses.

- Appliance Manufacturers: Manage thin-gauge metal sheets for refrigerators, ovens, or washers with precision.

- Small to Mid-Size Workshops: Scale storage without expanding your facility—customize the number of floors or units to match your current needs.

Technical Specifications: Built for Industrial Performance

Herochu doesn’t cut corners on engineering. Every component is designed for durability, speed, and reliability:

|

Specification

|

Details

|

|

Standard Sizes

|

3015/4015/4020/6015/6020/6025mm (fully customizable)

|

|

Load per Layer

|

3T or 5T (higher capacity available on request)

|

|

Number of Floors

|

Customizable (match your vertical space)

|

|

Number of Storage Units

|

Customizable (scale up as inventory grows)

|

|

Mode of Movement

|

Linear guide rail + chain (smooth, quiet operation)

|

|

Transmission Mode

|

Chain drive (low maintenance, high torque)

|

|

Vertical Lifting Speed

|

9m/min (fast, efficient vertical transport)

|

|

Inlet/Outlet Speed

|

12m/min (quick retrieval for time-sensitive jobs)

|

|

Plate Support

|

Optional selection (tailor to sheet thickness/type)

|

|

Certifications

|

CE, UE, ISO 9001 (meets global safety/quality standards)

|

Invest in Efficiency: Start at $8,999

For a limited time, the Herochu Automated Plate Warehouse starts at just $8,999—an affordable entry point for operations looking to boost productivity without breaking the bank. Unlike expensive custom systems that take months to install, Herochu’s solution is designed for quick setup, so you can start seeing results (faster retrieval, lower labor costs, better material protection) in weeks, not months.

And because we know every workshop is unique, our team works with you to customize every detail: from size and load capacity to drawer configuration and integration with your existing equipment. Whether you need a small 2-floor unit for a boutique fabricator or a 10-floor system for a large factory, we’ll build a solution that fits your workflow—not the other way around.

Why Choose Herochu?

At Herochu, we specialize in industrial storage solutions that solve real problems. Our Automated Plate Warehouse isn’t just a product—it’s a partnership. We offer:

- Global Certifications: CE, UE, and ISO 9001 certified, so you can trust in safety and quality.

- Customization: No two workshops are the same—we tailor our system to your needs.

- Support: From installation to maintenance, our team is here to ensure your system runs smoothly.

Stop wasting time on disorganized storage, manual labor, and damaged materials. The Herochu Automated Plate Warehouse is the smart, scalable solution to take your operation to the next level.

Ready to customize your system? Contact our team today to get a free quote and see how Herochu can transform your sheet metal storage.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racks & Lumber Racks for Sale

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & used heavy duty cantilever racks for sale

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Heavy Duty Plate Storage Warehouse

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automated Plate Warehouse with High Load Capacity

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5