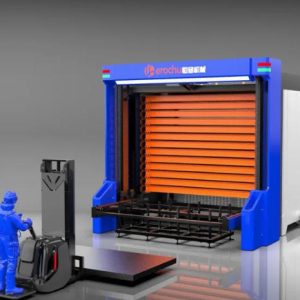

Automatic Heavy Duty Plate Storage Warehouse

The heart of the system is a quiet elevator running on precision linear guides and oil-bath chain. Servo motors lift at 9 m per minute and position each 3 t cradle within half a millimetre, so even paper-thin aluminum leaves the rack without a kink. The frame is modular: begin with five shelves for thirty plates, add more tiers later while production keeps running. Heights from three to twelve metres accept sheets as short as a 1.5 m square or as long as a 6 m ship-building panel. Heavy-line cradles rated at 5 t are available for armour plate or 40 mm mild steel, yet the entire machine draws less power than a domestic kettle while idle.

Herochu Heavy-Duty Automatic Plate Warehouse

From USD 8,999 | CE • UE • ISO 9001 | Tailor-built for your hall

From USD 8,999 | CE • UE • ISO 9001 | Tailor-built for your hall

Picture the scene that greets you every Monday: stacks of 4 mm aluminum leaned against the wall like dominoes, a pallet of 8 mm stainless blocking the aisle, and the remnants you know you bought last November nowhere to be found. One scratched sheet erases the profit on an entire laser program. The Herochu tower erases the scene instead. It stands a little taller than a forklift mast, yet swallows up to 150 t of plate in a footprint smaller than a family car. Tell the touchscreen what you need—steel, aluminum, copper, galvanized, 1 mm or 25 mm—and in just over a minute the correct sheet glides out, level with your laser table, surface pristine, weight already logged and sent to your MES. No climbing, no hunting, no second guesses.

The heart of the system is a quiet elevator running on precision linear guides and oil-bath chain. Servo motors lift at 9 m per minute and position each 3 t cradle within half a millimetre, so even paper-thin aluminum leaves the rack without a kink. The frame is modular: begin with five shelves for thirty plates, add more tiers later while production keeps running. Heights from three to twelve metres accept sheets as short as a 1.5 m square or as long as a 6 m ship-building panel. Heavy-line cradles rated at 5 t are available for armour plate or 40 mm mild steel, yet the entire machine draws less power than a domestic kettle while idle.

Storage happens horizontally, the only orientation that guarantees every sheet is reachable without unpacking half a stack. A cradle rolls out a full metre, giving overhead cranes, jib arms or vacuum lifters a clear run. Soft neoprene rails isolate metal from metal; vibration dampers kill the singing noise you get when chain meets steel. Doors can be manual swing gates for a tight budget, automatic roller shutters for high traffic, or PVC strip curtains if you share the air with a grinding bay. Inside, load cells record the exact mass of each resident and refuse to move if a sheet snags or a sling is left hooked—insurance auditors love the log file because it proves nobody took shortcuts.

Control feels like a smartphone that has swallowed a warehouse. Drag a finger across the floor map and watch plates light up in colors that tell you alloy, thickness, remnant length, next nesting job. Touch one, press retrieve, step back. While the carriage travels, the screen shows real-time position, motor torque and estimated arrival in seconds. If you run a night shift, queue up twenty requests, hit batch mode and walk away; the tower will cycle unattended, waiting at each step for the crane’s ready signal before it releases the next sheet. An OPC-UA gateway streams weight and dimension data to Lantek, SigmaNEST, TruTops or your homemade ERP—no spreadsheets retyped at midnight.

Installation respects the calendar you already have. The tower arrives in knocked-down modules that slide through a standard 3 m dock door. Two technicians and your own electrician spend two days bolting frames, one day connecting cables, one afternoon calibrating lasers. No pit, no anchor resin deeper than a parking-bolt, no fire department inspection beyond what you already own. Should you relocate, undo thirty bolts, load the sections on a flatbed and rebuild across town the same week; the positional memory stays on the SD card in the PLC.

The pay-back conversation is short. A single forklift driver costs more per year than an entry-level Herochu. Add the square metres you suddenly stop renting, the remnants you finally reuse, the corner damage that no longer happens, and most shops cross into profit before the fourth month. One Ohio fabricator freed an entire bay, dropped scrap from 4 % to 1 % and used the reclaimed space to install a deburring cell that now bills an extra half million a year. A Dutch subcontractor feeds a 6 kW laser lights-out; inventory turns every three days instead of eleven, liberating three hundred and eighty thousand Euro of working capital. Their words, not ours: “the tower paid for itself faster than any machine on our books.”

Security is engineered, not added later. Category-three safety PLCs monitor light grids, cradle position and motor torque; any fault applies mechanical brakes with a stopping distance under five centimetres. Earthquake brackets rated for 0.4 g keep 5 t sheets stable when the ground shakes. Cradles are zinc-plated steel; there is no plastic to melt or drip onto the lasers below. Doors lock while the carriage moves, and an internal hatch prevents anyone from stepping into the liftway during maintenance. Should you store expensive copper or pre-painted material, opt for a dehumidifier cartridge that keeps relative humidity below forty percent, eliminating white rust for two years without VCI paper.

Choices follow the shape of your work. Need to feed both a 3 m shear and a 6 m laser? Specify dual bay outlets on opposite faces. Store only 0.5 mm automotive skins? Reduce cradle pitch to sixty millimetres and fit forty shelves instead of twenty. Run a job shop that quotes tonight and cuts tomorrow? Let the algorithm learn your nesting habits and park the most likely remnant sizes on the fastest retrieval levels. Heavy fabricators can order the 5 t package with case-hardened rollers and a chain tensile rating double the safety factor, enough for twenty-five millimeter high-strength steel used in crane booms.

After-sales life is simple. The chain is common industrial size; a replacement link costs a few dollars and fits with a standard breaker. Bearings are sealed for life, rated for fifty thousand kilometres of travel—about twenty years in three-shift duty. Remote diagnostics tunnel in through a secure VPN; most alarms are solved by firmware update while you sleep. When eventually a cradle wears, unbolt four screws, slide the old unit out, drop the new one in—no welding, no alignment telescope, no factory technician on a plane.

Herochu towers are running in climates from the humid Gulf Coast to the sub-zero Nordics, in plants cutting everything from art-deco brass cladding to armor plate for military vehicles. Wherever they stand, the story repeats: floor space handed back to production, forklifts retired, labor redirected to value-adding work, surface quality that leaves customers wondering why competitors still deliver scratched panels. If your business card says laser, plasma, punch, shear, press-brake or panel bender, the only question left is how many months you want to give away in rent and scrap before you join them.

Send a floor plan, a list of your top five sheet sizes, and the yearly tonnage you handle. Within twelve hours we return a 2D drawing that slots between your existing crane rails, a cycle-time simulation, and a fixed-price quotation that includes delivery, commissioning and operator training. The first cradle can carry your company name laser-etched on a stainless plate—small reward for deciding that chaos belongs to the past, not to the next shift.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racks & Lumber Racks for Sale

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & used heavy duty cantilever racks for sale

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Heavy Duty Plate Storage Warehouse

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automated Plate Warehouse with High Load Capacity

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5