Automatic Loading And Unloading Sheet Metal Fiber Laser Cutting Machine

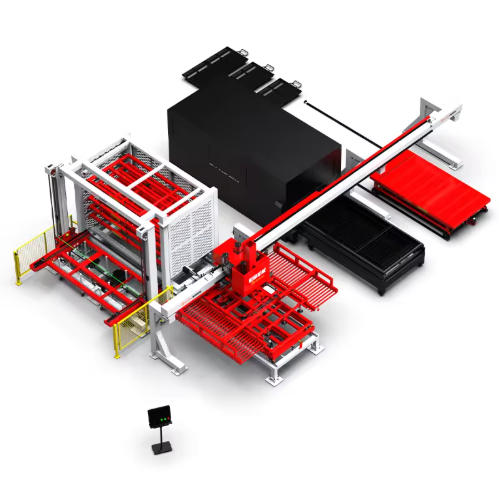

The Herochu Automatic Loading and Unloading Sheet Metal Fiber Laser Cutting Machine confronts this reality head-on. This is not an accessory; it is a fully integrated production cell engineered to synchronize material handling with cutting execution. We’ve moved beyond simply automating the laser to re-engineering the entire workflow, transforming your shop’s output from a series of tasks into a continuous, flowing process.

The Uninterrupted Cut: Redefining Laser Productivity with Integrated Automation

In the modern metal fabrication landscape, the race for efficiency is won or lost not at the laser head, but in the critical moments between cuts. While laser cutting speeds have skyrocketed, many shops find their most advanced asset hamstrung by a primitive process: the manual loading of raw sheets and the tedious unloading of finished parts. This human-paced cycle creates inevitable bottlenecks, turning your high-speed laser into a stop-start operation that waits for labor.

The Herochu Automatic Loading and Unloading Sheet Metal Fiber Laser Cutting Machine confronts this reality head-on. This is not an accessory; it is a fully integrated production cell engineered to synchronize material handling with cutting execution. We’ve moved beyond simply automating the laser to re-engineering the entire workflow, transforming your shop’s output from a series of tasks into a continuous, flowing process.

The Anatomy of a Self-Sufficient Production Cell

At its core, the Herochu system is a masterclass in synchronized mechanics and intelligent control, designed to eliminate the two greatest thieves of productivity: loading delays and unloading chaos.

1. The High-Density Raw Material Library:

The process begins with a robust, multi-level storage tower, offering between 8 and 13 floors with a load capacity of 3T or 5T per layer. This is your centralized, on-demand material bank. It holds a queue of raw sheets, ready for deployment, eliminating the constant forklift traffic and floor space consumption of traditional sheet management. Available in standard sizes from 3015mm to 6025mm, this storage unit is the foundational element that enables extended unmanned production runs.

2. The Precision Material Handling System:

Speed is nothing without reliability. The system employs a chain drive transmission moving along a linear guide rail—a combination chosen for its proven durability and ability to handle heavy loads with consistent precision. The vertical lifting speed of 9m/min and the inlet/outlet speed of 12m/min are engineered not for maximum velocity, but for optimal cycle time—fast enough to keep pace with your laser, yet smooth enough to guarantee perfect sheet placement every time, preventing misalignment that can ruin a entire sheet.

3. The Intelligent Unloading Methodology:

This is where the Herochu system truly diverges from basic automation. We understand that “unloading” isn’t a single action but a critical phase that determines downstream efficiency. The system is designed to handle the post-cut process with finesse:

-

Complete Sheet Evacuation: Using a robust comb or gripper system, the entire cut sheet—including the skeleton and nested parts—is swiftly removed from the machine table and placed onto a designated pallet. This clears the deck instantly for the next raw sheet, dramatically reducing table swap times.

-

Paving the Way for Sorting: This efficient evacuation is the crucial first step toward organized part management. By automatically clearing the table, it sets the stage for subsequent manual sorting at a dedicated station or for integration with advanced robotic sorting arms, preventing a logjam at the machine itself.

Navigating the Automation Spectrum: A Strategy, Not Just a Product

Choosing the right level of automation is critical. The Herochu system is built on a modular philosophy, allowing you to select a configuration that aligns with your specific production challenges and growth trajectory.

Configuration A: The Productivity Foundation (Auto-Load, Manual Unload)

This entry-point configuration tackles the most common bottleneck: raw material loading. An automated gantry with a vacuum lifter precisely places new sheets onto the machine table. While an operator still unloads and sorts parts, this system leverages the machine’s dual-table function. The laser cuts on one table while the operator unloads the other, and the auto-loader pre-positions the next sheet. This is ideal for shops with high-mix, lower-volume jobs where manual sorting provides necessary flexibility.

Configuration B: The Throughput Accelerator (Auto-Load & Complete Sheet Unload)

This is a leap forward in minimizing machine idle time. Here, the system not only loads the raw sheet but also automatically unloads the entire cut sheet—skeleton and all—immediately after the cut is complete. This is the solution to the problem of short cutting cycles on thin materials, where the cut time is less than the manual unloading/loading time. The machine never waits; as soon as one table exits the cutting chamber, the other is ready to enter.

Configuration C: The Fully Unmanned Vision (Integrated Sorting & Palletizing)

The pinnacle of laser automation, this configuration incorporates a robotic sorter equipped with a vacuum or magnetic gripper. As parts are unloaded, this subsystem identifies, picks, and stacks finished parts onto organized pallets, ready for the next manufacturing step. This represents the ultimate achievement in lights-out manufacturing, turning the laser cell into a truly self-managing unit.

The Compounding Returns on a Strategic Investment

Starting at $8,900, integrating Herochu automation is a calculated investment that delivers a rapid and multifaceted return.

-

Eliminate Machine Idle Time: Achieve a continuous workflow where your laser cutter’s productivity is defined by its maximum cutting capacity, not by the speed of an operator. This directly translates to more billable hours per day and a faster return on your capital investment.

-

Reallocate Human Expertise: Free your skilled workforce from the monotonous and physically demanding tasks of lifting sheets and digging for parts. Redeploy them to value-added roles in quality control, programming, finishing, and assembly, thereby elevating your shop’s entire capability.

-

Enhance Operational Safety & Order: Remove the primary source of musculoskeletal strain and potential for sheet drops. The consolidated storage and automated handling create a cleaner, safer, and more organized workshop environment, reducing accident risks and improving morale.

-

Gain a Predictable, Manageable Flow: With CE, UE, and ISO 9001 certification, you are investing in a system built to international standards of safety and quality. The automated workflow brings predictability to your production schedule, allowing for more accurate lead time quoting and smoother overall operations.

Stop allowing manual handling to dictate the limits of your technology. The Herochu Automatic Loading and Unloading System is the key to unlocking the full, latent potential within your fiber laser cutter, transforming it from a standalone machine into the beating heart of a streamlined, high-output production cell.

Contact a Herochu automation consultant today. Discuss your material mix, production volumes, and operational challenges. We will help you navigate the automation spectrum to configure a system that delivers an immediate and sustained competitive advantage.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Double Vs. Single-Sided Cantilever Racking

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automated unloading system designed for laser steel plate cutting machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading And Unloading Sheet Metal Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic loading and unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Laser Automation:Loading and unloading systems for laser cutting machines

Read moreRated 0 out of 5