Automatic Sheet Metal storage racking systems

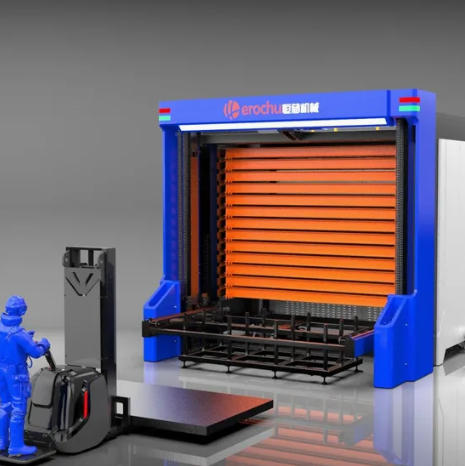

A laser cutter is only fast when the right plate is already at the loading table. In most shops the bottleneck is not the beam, it is the twenty minutes spent backing a forklift between racks, tugging a 3-ton bundle, unstrapping, counting, re-strapping, and finally praying the gauge sticker survived the ride. Herochu’s automated tower erases that script. Sheet metal is stored eleven levels high, retrieved by servo-driven chains, and delivered to a waist-high picking bay in under sixty seconds—while the operator is still nesting the previous job.

Herochu Automatic Sheet Metal Storage Racking Systems

Turn sheet metal into silent inventory that fetches itself.

From US $4 399 | CE, ISO 9001 | Built to your bay size

Turn sheet metal into silent inventory that fetches itself.

From US $4 399 | CE, ISO 9001 | Built to your bay size

A laser cutter is only fast when the right plate is already at the loading table. In most shops the bottleneck is not the beam, it is the twenty minutes spent backing a forklift between racks, tugging a 3-ton bundle, unstrapping, counting, re-strapping, and finally praying the gauge sticker survived the ride. Herochu’s automated tower erases that script. Sheet metal is stored eleven levels high, retrieved by servo-driven chains, and delivered to a waist-high picking bay in under sixty seconds—while the operator is still nesting the previous job.

The heart is a vertical carousel built from the same structural steel we use for port cranes. Instead of cars it carries removable cassettes that can cradle anything from 0.5 mm aluminium cosmetic sheet to 25 mm hot-rolled plate. One tower typically replaces 280 m² of traditional floor stacking with a 6 m² footprint, gaining back rentable space or room for an extra laser. Yet the real gain is tempo: a goods-to-person rhythm that keeps takt times honest and night-shift crews calm.

How it moves

Cassettes ride on linear guide rails rated for 3 t per level and 30,000 continuous cycles. A 1.5 kW geared servo lifts at 9 m/min while the chain shuttle transfers in and out at 12 m/min—fast enough to stay ahead of a 12 kW fibre laser running nested 15 mm mild-steel parts. Positioning repeatability is ±1 mm, so a vacuum lifter or magnetic manipulator can dock without human eyes. The whole choreography is held in a PLC with a 7-inch colour touchscreen that speaks G-code, OPC-UA and plain English. Tap “4 mm 316L” and watch the tower present the lightest-aged pallet first; swipe right to see real-time weight, remnant area and heat number captured automatically by the built-in load cells.

Cassettes ride on linear guide rails rated for 3 t per level and 30,000 continuous cycles. A 1.5 kW geared servo lifts at 9 m/min while the chain shuttle transfers in and out at 12 m/min—fast enough to stay ahead of a 12 kW fibre laser running nested 15 mm mild-steel parts. Positioning repeatability is ±1 mm, so a vacuum lifter or magnetic manipulator can dock without human eyes. The whole choreography is held in a PLC with a 7-inch colour touchscreen that speaks G-code, OPC-UA and plain English. Tap “4 mm 316L” and watch the tower present the lightest-aged pallet first; swipe right to see real-time weight, remnant area and heat number captured automatically by the built-in load cells.

Safety that is not an afterthought

No one walks under hanging load because the load is inside the frame. Doors are laser-locked; if an operator opens a panel the servo regenerates and parks the carriage in 300 ms. Fire suppression nozzles can be pre-piped; each cassette is a flame-retardant tray that keeps oil drips off the floor. For insurance audits we provide a full FEM 10.2.02 static report and CE declaration of incorporation—no hidden extras.

No one walks under hanging load because the load is inside the frame. Doors are laser-locked; if an operator opens a panel the servo regenerates and parks the carriage in 300 ms. Fire suppression nozzles can be pre-piped; each cassette is a flame-retardant tray that keeps oil drips off the floor. For insurance audits we provide a full FEM 10.2.02 static report and CE declaration of incorporation—no hidden extras.

Integration without religion

The tower is happy to chat with Amada, Trumpf, Bystronic, Prima Power or a homemade gantry loader. Handshake can be as simple as a 24 V “material ready” signal or as chatty as Ethernet/IP with automatic remnant return. If the laser asks for 2 × 1 m sheets from the same heat, the tower sorts and queues them, then books the skeleton back into an open slot so you do not pay to scrap air. Should you add a second laser next year the license is already included; just call us to bolt on another bay.

The tower is happy to chat with Amada, Trumpf, Bystronic, Prima Power or a homemade gantry loader. Handshake can be as simple as a 24 V “material ready” signal or as chatty as Ethernet/IP with automatic remnant return. If the laser asks for 2 × 1 m sheets from the same heat, the tower sorts and queues them, then books the skeleton back into an open slot so you do not pay to scrap air. Should you add a second laser next year the license is already included; just call us to bolt on another bay.

Sizes that start tall and grow taller

Standard widths mirror common sheet sizes: 3015, 4015, 4020, 6015, 6020, 6025 mm. Height begins at 4 m and climbs in 500 mm increments until it kisses the rafters—some customers run 14 m inside a retrofit hall. Load per shelf is 3 t as standard, 5 t on request, 10 t if we widen the rail profile. Each cassette can be split into two half-width trays for remnant segregation or fitted with vertical dividers for aluminium/bronze separation to avoid cross-contamination. If tomorrow you decide to store 12 m long composite panels we unbolt the roof section, splice extra rail, and the tower wakes up taller the same afternoon.

Standard widths mirror common sheet sizes: 3015, 4015, 4020, 6015, 6020, 6025 mm. Height begins at 4 m and climbs in 500 mm increments until it kisses the rafters—some customers run 14 m inside a retrofit hall. Load per shelf is 3 t as standard, 5 t on request, 10 t if we widen the rail profile. Each cassette can be split into two half-width trays for remnant segregation or fitted with vertical dividers for aluminium/bronze separation to avoid cross-contamination. If tomorrow you decide to store 12 m long composite panels we unbolt the roof section, splice extra rail, and the tower wakes up taller the same afternoon.

Inventory that watches itself

Every入库 entry triggers three records: weight from four load cells, a snapshot from the bay camera, and a QR label printed on the spot. The system learns average usage per SKU and will whisper—via e-mail or Slack—when remnant drops below the safety stock you set. Month-end spreadsheets write themselves: export CSV, upload to SAP, job done. For traceability critical jobs we can even lock a cassette until the MES releases the heat number to the laser, guaranteeing aerospace or nuclear paperwork without a second keyboard.

Every入库 entry triggers three records: weight from four load cells, a snapshot from the bay camera, and a QR label printed on the spot. The system learns average usage per SKU and will whisper—via e-mail or Slack—when remnant drops below the safety stock you set. Month-end spreadsheets write themselves: export CSV, upload to SAP, job done. For traceability critical jobs we can even lock a cassette until the MES releases the heat number to the laser, guaranteeing aerospace or nuclear paperwork without a second keyboard.

Labour rethink

One operator can tend two lasers fed by a single tower, cutting direct labour by half and freeing certified forklift drivers for shipping. In regions where night staff is impossible to find the tower keeps the lights on: load it at 5 p.m., let it run unmanned until 2 a.m., and sweep skeletons in the morning. Customers report payback between nine and fourteen months depending on shift model—calculated only on labour and floor space, before scrap reduction is counted.

One operator can tend two lasers fed by a single tower, cutting direct labour by half and freeing certified forklift drivers for shipping. In regions where night staff is impossible to find the tower keeps the lights on: load it at 5 p.m., let it run unmanned until 2 a.m., and sweep skeletons in the morning. Customers report payback between nine and fourteen months depending on shift model—calculated only on labour and floor space, before scrap reduction is counted.

Energy footprint

Lifting 3 t eleven metres high sounds hungry until you see the regenerative drive: on descent the servo pumps current back into the grid, cutting peak consumption by 28 %. Average duty cycle for a three-shift shop is 2.1 kWh per day—less than the air compressor leak nobody has time to chase. If you pair the tower with rooftop PV the controller can schedule heavy lifts when surplus solar is available, shaving another few cents off every retrieved sheet.

Lifting 3 t eleven metres high sounds hungry until you see the regenerative drive: on descent the servo pumps current back into the grid, cutting peak consumption by 28 %. Average duty cycle for a three-shift shop is 2.1 kWh per day—less than the air compressor leak nobody has time to chase. If you pair the tower with rooftop PV the controller can schedule heavy lifts when surplus solar is available, shaving another few cents off every retrieved sheet.

Service that arrives before you know you need it

All moving parts are visible from a catwalk; no proprietary snake oil. Bearings and chains are DIN standard and can be replaced with tools already in your maintenance room. A vibration sensor on the carriage listens for anomalies; when tension drifts 5 % the PLC pings you with an Amazon-style “part en-route” message. We keep critical spares in Rotterdam, Chicago and Suzhou, so even a 24-hour line-down risk is covered without airfreight drama.

All moving parts are visible from a catwalk; no proprietary snake oil. Bearings and chains are DIN standard and can be replaced with tools already in your maintenance room. A vibration sensor on the carriage listens for anomalies; when tension drifts 5 % the PLC pings you with an Amazon-style “part en-route” message. We keep critical spares in Rotterdam, Chicago and Suzhou, so even a 24-hour line-down risk is covered without airfreight drama.

Price, but value first

A four-bay starter tower (4020 mm × 5 t × 8 levels) lands at $4 399 ex-works, including software, commissioning and operator training. That is roughly the annual salary of one forklift driver who still calls in sick. Finance leases are available, and in some EU territories the investment qualifies for energy-efficiency subsidies that repay 20 % of CapEx within the first fiscal year. When capacity doubles you add bays instead of real-estate, protecting the original ticket against inflationary rent.

A four-bay starter tower (4020 mm × 5 t × 8 levels) lands at $4 399 ex-works, including software, commissioning and operator training. That is roughly the annual salary of one forklift driver who still calls in sick. Finance leases are available, and in some EU territories the investment qualifies for energy-efficiency subsidies that repay 20 % of CapEx within the first fiscal year. When capacity doubles you add bays instead of real-estate, protecting the original ticket against inflationary rent.

The quiet revolution

Sheet metal is the last industrial commodity still man-handled like sacks of grain. Herochu’s automated tower ends that anachronism, swapping sweat and square metres for silent, repeatable logic. Give the laser what it wants before it asks, reclaim the floor for value-adding machines, and let your people graduate from fork jockeys to process engineers. The tower does not just store steel; it stores time—and time, in fabrication, is the only margin that never shrinks.

Sheet metal is the last industrial commodity still man-handled like sacks of grain. Herochu’s automated tower ends that anachronism, swapping sweat and square metres for silent, repeatable logic. Give the laser what it wants before it asks, reclaim the floor for value-adding machines, and let your people graduate from fork jockeys to process engineers. The tower does not just store steel; it stores time—and time, in fabrication, is the only margin that never shrinks.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty cantilever sheet metal rack

Read moreRated 0 out of 5