Cantilever Racking & Shelving System

The Herochu Promise: Quality, Certification, and Customization

We understand that an industrial storage system is a long-term investment. Every Herochu Cantilever Rack is constructed from prime-grade materials and manufactured to the most rigorous quality standards, as evidenced by our CE, UKCA, and ISO 9001 certifications. This is your guarantee of structural integrity and operational safety.Furthermore, we reject the one-size-fits-all approach. Our systems are highly customizable, starting at $3,989. We work with you to determine the ideal column height, arm length, and bay configuration to meet your specific load requirements and spatial constraints.Stop allowing awkwardly shaped materials to dictate the limits of your workshop’s efficiency and safety. Embrace the open-access, flexible power of Herochu Cantilever Racking.

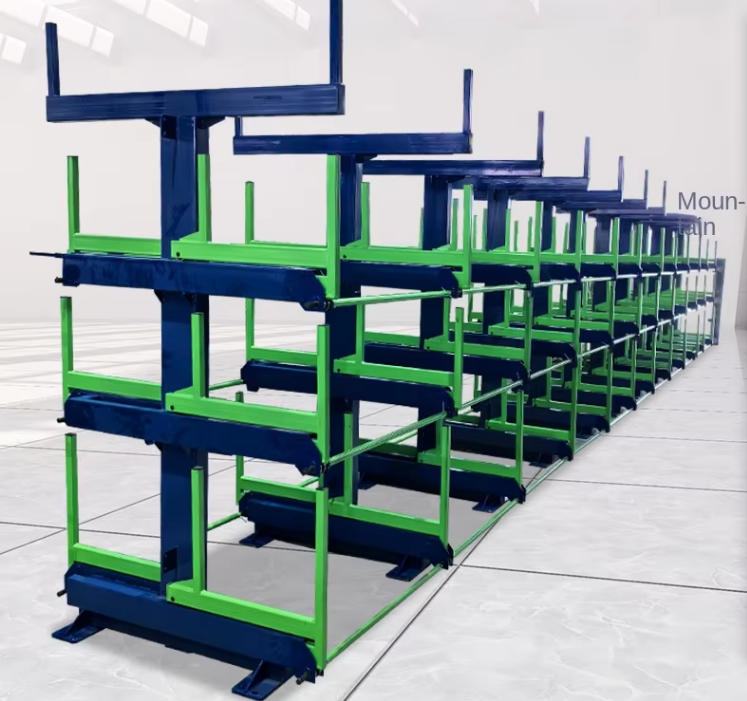

The Herochu Cantilever Design Principle: Engineered Simplicity for Uncompromising Strength

At its core, the cantilever concept is a masterpiece of structural engineering. By eliminating front-column obstructions, it creates a completely open, accessible storage bay. The Herochu system refines this principle with a focus on durability, flexibility, and ease of use.

Deconstructing the Components:

-

Robust Upright Columns: These are the backbone of the system, fabricated from high-tensile, cold-rolled steel. They are designed to handle immense vertical loads and the significant cantilevered forces exerted by the arms. Our columns feature a precision-punched design for easy, tool-free adjustment of the arm levels.

-

Heavy-Duty Load Arms: The arms are the workhorses, slotting securely into the columns at your desired height. They are engineered with a slight upward tilt at the end to prevent stored items from accidentally sliding off. Available in various lengths, these arms define the depth of your storage and are built to resist bending under full load.

-

Structural Base and Bracing: Stability is non-negotiable. The system features a reinforced base that can be anchored to the floor for absolute seismic stability. Diagonal bracing between the columns ensures the entire structure remains rigid and wobble-free, even when fully loaded and during the active loading/unloading process.

-

Optional Accessories: To tailor the system to your specific needs, we offer a range of accessories, including wire decking to prevent small items from falling through, end stops for added security, and specialized protective arm sleeves to prevent marring on sensitive materials like anodized aluminum or finished wood.

The Strategic Advantage: Where Herochu Cantilever Racking Becomes a Game-Changer

Understanding the “why” behind this system is key to unlocking its full potential. Its advantages are most pronounced in specific, high-impact scenarios.

1. Unobstructed, 100% Accessible Storage

The single greatest benefit of the cantilever design is the complete absence of vertical obstructions. A forklift operator can approach the rack from any point along its frontage and directly access the exact beam, pipe, or panel they need. There is no navigating around posts or maneuvering within a confined space. This direct-line access slashes retrieval and storage times, turning a complex material-handling task into a simple, point-to-point operation.

2. Unparalleled Flexibility and Adaptability

Your inventory is not static, and your storage shouldn’t be either. The ability to adjust the height of the arms on the columns is a transformative feature. One week you might need to store tall, bulky pallets of composite panels; the next, you might need to reconfigure for multiple levels of shorter bar stock. With a Herochu cantilever system, this reconfiguration requires no special tools and takes mere minutes. It is a storage solution that evolves with your business, preventing the obsolescence that plagues fixed shelving systems.

3. Maximized Vertical Space Utilization

This system is the ultimate tool for leveraging the cubic volume of your workshop. By building upwards, you effectively compress the sprawling footprint of floor-stacked materials into a narrow, organized aisle. The space you reclaim can be monumental. This freed-up floor area can be used for additional assembly stations, new machinery, or simply to create wider, safer traffic aisles for forklifts and personnel, fundamentally improving the flow of your entire operation.

4. Enhanced Material Integrity and Safety

By storing long items on individual, supported arms, you eliminate the crushing weight and abrasive contact of floor piling. Each item rests securely in its own space, protected from damage. From a safety perspective, the system eliminates the hazard of leaning stacks and creates a predictable, organized environment. The risk of items being knocked over or becoming entangled is virtually eliminated, creating a safer workspace for everyone.

Making the Critical Choice: Cantilever Racking vs. Drawer Systems

It is essential to recognize that no single storage solution is universally perfect. The choice between a Herochu Cantilever Rack and a Herochu Sheet Metal Drawer Rack is a strategic one, dictated entirely by the materials you handle and your access patterns.

Choose a Herochu Cantilever Racking System when you are storing:

-

Long, bulky items like structural steel, pipes, tubes, and lumber.

-

Large, flat items that can be stored on edge, such as doors, panels, or plastic sheets.

-

Irregularly shaped items that would not fit efficiently in a standard shelf or drawer.

-

Materials that are typically accessed in bulk or where “last-in, first-out” (LIFO) access is acceptable.

Opt for a Herochu Sheet Metal Drawer System when your primary need is:

-

Storing flat sheets of metal (steel, aluminum, etc.).

-

Requiring 100% selectivity and “first-in, first-out” (FIFO) access to any individual sheet without moving others.

-

Protecting the pristine surface quality of expensive, pre-finished materials from scratches and damage.

-

Integrating storage with automated retrieval processes.

The Herochu Promise: Quality, Certification, and Customization

We understand that an industrial storage system is a long-term investment. Every Herochu Cantilever Rack is constructed from prime-grade materials and manufactured to the most rigorous quality standards, as evidenced by our CE, UKCA, and ISO 9001 certifications. This is your guarantee of structural integrity and operational safety.

Furthermore, we reject the one-size-fits-all approach. Our systems are highly customizable, starting at $3,989. We work with you to determine the ideal column height, arm length, and bay configuration to meet your specific load requirements and spatial constraints.

Stop allowing awkwardly shaped materials to dictate the limits of your workshop’s efficiency and safety. Embrace the open-access, flexible power of Herochu Cantilever Racking.

Contact us today for a free, no-obligation storage assessment. Let our experts help you design a system that doesn’t just store your materials, but actively works to streamline your workflow and unlock the full three-dimensional potential of your facility.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Professional Metal Sheet Storage Systems Manufacturer

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Efficient and Safe Industrial Metal Sheet Storage Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever steel bar tubing & pipe storage racks

Read moreRated 0 out of 5