Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Warehouse air is cheap until you fill it with the wrong rack. A pallet shelf bows under 20-foot casing, a stack of conduit rolls across the aisle, and the inspector starts measuring clearance to the sprinkler head. Herochu cantilever racks and heavy-duty shelf systems remove that guessing game by giving every tube, beam, or plastic extrusion its own steel cradle—no front column, no reach limits, no daily wrestling match with a 2-ton pup joint.

Herochu Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Steel that stands still while your inventory moves—starting at $3,099, CE/UE/ISO 9001 certified, and cut to the centimetre you ask for.

Steel that stands still while your inventory moves—starting at $3,099, CE/UE/ISO 9001 certified, and cut to the centimetre you ask for.

Warehouse air is cheap until you fill it with the wrong rack. A pallet shelf bows under 20-foot casing, a stack of conduit rolls across the aisle, and the inspector starts measuring clearance to the sprinkler head. Herochu cantilever racks and heavy-duty shelf systems remove that guessing game by giving every tube, beam, or plastic extrusion its own steel cradle—no front column, no reach limits, no daily wrestling match with a 2-ton pup joint.

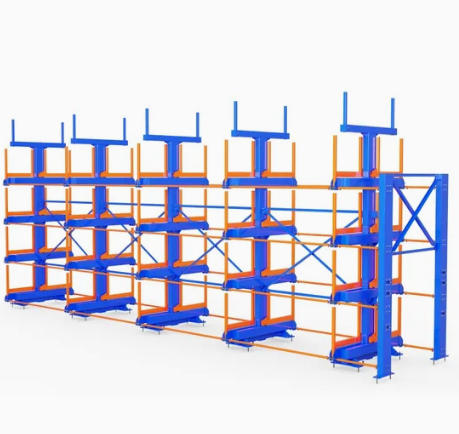

Front-Free Design, Forklift-Friendly Life

Traditional shelving forces the mast into the pick path. Cantilever arms project clear of the upright, so a 6-ton bundle glides straight off the truck and onto the rack in one motion. Whether you store 60 mm stainless micro-bore or 1,200 mm spiral-weld, arms telescope on 50 mm centres and lock with a zinc-plated pin rated for 5 t shear. The result is a 40 % reduction in average handling time recorded at a Norwegian pipe mill: one driver, one lift, no second shift paid to babysit inventory.

Capacities You Can Spell in Steel, Not Marketing

Start small with the HC-CS6050—three arms, 2 t each, 8 t total—perfect for PVC conduit or composite tubing. Step up to the HC-CD9095 and you are looking at 5 t per arm and 35 t per tower, enough for 9 m drill risers still in the protective sleeve. Need more? We punch holes for 12 m uprights, weld double-box arms, and deliver 42 t per bay without a prototype drawing. Every weld is mapped, ultrasonic-checked, and logged to the CE declaration that travels with the rack; your insurer signs off before the first load lands.

Honeycomb or Cantilever—Same Skeleton, Different Day

Some stock wants horizontal support, other stock wants vertical segregation. Swap the flat cantilever arm for a honeycomb cassette and the same tower now accepts slit coils, bar stock, or plastic sheet. One Midwest electrical distributor runs orange cantilever arms on the south side for rigid steel conduit, blue honeycomb cells on the north side for PVC trunking—one rack footprint, two commodity codes, zero pick confusion.

Motors Where You Need Them, Manual Where You Don’t

Not every bay justifies a drive motor—until you handle 300 picks per shift. Herochu’s PLC frequency-conversion carriage bolts to any arm and rolls out the load at 0.3 m/s, smooth enough for wrapped polished tube yet fast enough to feed an automated cutter. The hand-held remote docks on the upright when the rush ends; switch back to manual pins and you pay zero standby power. Invertek drives are stocked in Chicago, Düsseldorf, and Dubai, so a replacement VFD ships overnight, not next quarter.

Steel That Forgives the Weather You Forgot to Plan For

Outdoor pipe yards see UV, road salt, and the occasional hurricane. Uprights are 5″ square, 6 mm wall, shot-blasted SA 2.5, zinc-primed, then finished with 80 µm polyester powder rated for 1,000 h salt-spray. Bolt heads receive a wax over-coat so threads spin free even after a winter of calcium chloride. Optional hot-dip galvanizing pushes corrosion resistance to 2,400 h for coastal petrochemical sites—still cut, welded, and drilled to the same tight tolerance because we galvanize after fabrication, not before.

Seismic? No Problem—Just Add Stiffeners

A rack in Santiago once walked 200 mm during an 8.0 tremor; the pipe stayed put because we added rear sway braces and base plates epoxied to a 200 mm concrete slab. Herochu supplies calculated reactions for Zone 4, Importance Factor 1.5, and will stamp drawings for the local building department. If the ground shakes, the inventory dances but does not fall.

Colour That Organises, Not Just Decorates

Orange arms for carbon steel, blue for stainless, grey for PVC—visual factory rules baked into the paint schedule. End-stops accept adhesive barcode labels or RFID tags, so the WMS knows the 6″ SCH40 bundle moved at 14:27 and the 4″ SCH80 remains. One scan updates inventory, triggers reorder, and emails the purchaser before the forklift reaches the bay door.

Floor Space Math That Pays for Itself

A horizontal bundle of 10 m casing needs 12 m² on the ground and another 12 m² for access. Stand it vertical in a Herochu tower and the footprint shrinks to 1.2 m²—one hundred pipes per square metre instead of four. A Houston OCTG supplier converted 1,800 m² of outdoor storage into 200 m² under roof, then leased the leftover acre for trailer parking at $4/ft² per month. The rack paid for itself in eleven months; the rent cheque arrives every 30 days.

Assembly Without the Circus

Uprights ship pre-punched, arms arrive labelled, and bolts are bagged by step number. Two millwrights, two 19 mm wrenches, and 90 minutes erect a 6 m double-sided bay—no boom lift, no certified welder, no hot-work permit. A QR code on the mast links to a 3-minute assembly video shot in one take so the night shift can add a level while day shift drinks coffee.

Sustainability Welded In, Not Bolted On

Steel averages 72 % recycled content, powder coat lines run on solar, and returnable steel frames replace timber crating. When you reconfigure, unbolt and reuse 98 % of components; only the footplates stay epoxied to the floor. Your ESG report gets a paragraph, landfill gets nothing.

Lead Times Measured in Days, Not Fiscal Quarters

Standard 3-ton and 5-ton arms sit in raw stock; uprights are punched within 24 h of order release. A six-bay cantilever row leaves the plant in 10 business days; custom arm lengths or hot-dip finish add five. Miss the promised dock date and we refund the expedite fee—no asterisks, no fine print.

Talk to Someone Who Has Loaded Pipe at 5 a.m.

Call 1-800-HEROCHU and you reach a former yard foreman, not a script reader. Email a napkin sketch; we return a stamped drawing overnight. Need a load test? We will video a 2.5× proof and send the MTRs with the invoice. Your inspector signs off before the truck backs in.

Ready to Give Every Tube a Home?

Measure the longest length, the heaviest bundle, and the ceiling you can’t hit. Punch those three numbers into the Build-My-Rack widget and watch a live quote populate—freight included, taxes if you want them, payback curve attached. Or dial the number, ask for cantilever, and speak to someone who knows why a pup joint always rolls the wrong way.

Herochu Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Stop restacking chaos and start stacking margin—one steel arm at a time.

Stop restacking chaos and start stacking margin—one steel arm at a time.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Warehouse Cantilever Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

High quality warehouse pipe racking systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industrial Roll-out Telescopic Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Storage solution for long timber packs

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty Storage racks for steel profiles

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Storage steel sheets racks measuring 1500×3000 or 3500mm for 3t sheets

Read moreRated 0 out of 5