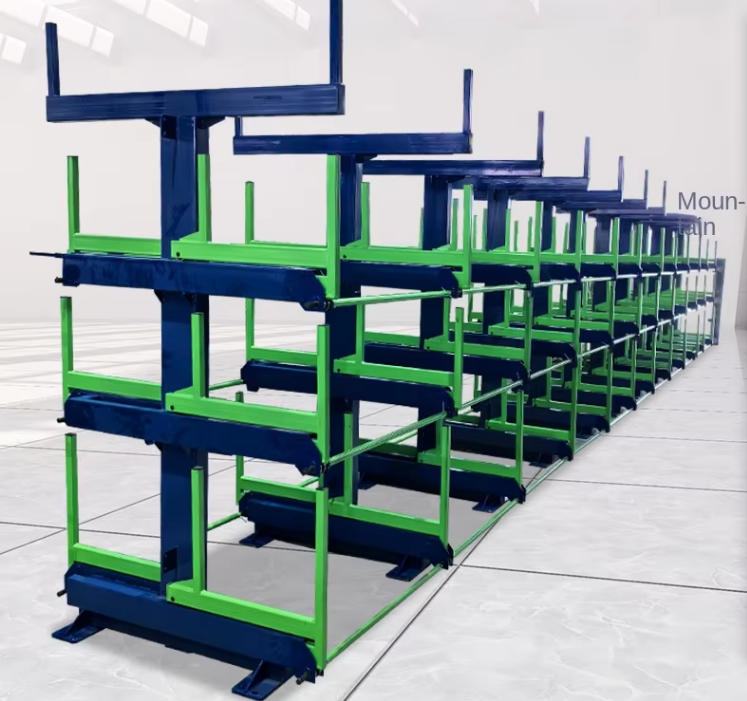

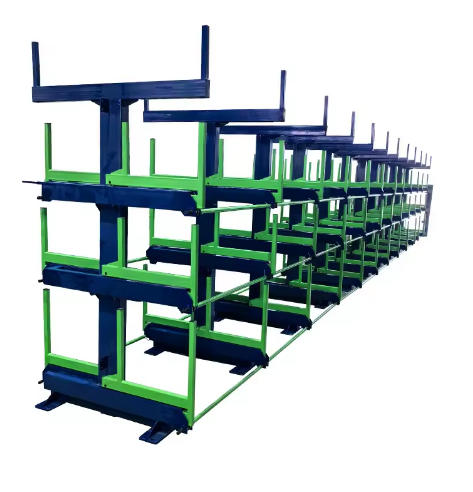

Cantilever Steel Bar, Tubing & Pipe Storage Racks

The Herochu Cantilever System for Steel Bar, Tubing & Pipe is a masterclass in intelligent, heavy-duty organization. Designed specifically for long, bulky, and heavy items, this system transforms your storage area from a liability into a model of efficiency and safety. Starting at just $3,890 and fully customizable to your workshop’s unique dimensions and load requirements, a Herochu Cantilever Rack is a strategic investment that pays for itself in recovered time, space, and peace of mind. Every component is CE, UE, and ISO 9001 certified, guaranteeing a level of quality and safety that meets the most rigorous international standards.

Tame the Tangle: The Herochu Cantilever System for Organized Bar, Tubing & Pipe Storage

If your workshop floor is a chaotic landscape of leaning pipes, scattered lumber, and tangled bar stock, you’re living with more than just an eyesore. You’re facing a daily drain on productivity, a significant safety risk, and a massive waste of your most valuable asset: your floor space. Standard shelving fails these materials completely, leaving you with unstable piles that are difficult to access and dangerous to manage. This is the industrial storage problem that the Herochu Cantilever Rack is engineered to solve.

We don’t just manufacture storage; we deliver order. The Herochu Cantilever System for Steel Bar, Tubing & Pipe is a masterclass in intelligent, heavy-duty organization. Designed specifically for long, bulky, and heavy items, this system transforms your storage area from a liability into a model of efficiency and safety. Starting at just $3,890 and fully customizable to your workshop’s unique dimensions and load requirements, a Herochu Cantilever Rack is a strategic investment that pays for itself in recovered time, space, and peace of mind. Every component is CE, UE, and ISO 9001 certified, guaranteeing a level of quality and safety that meets the most rigorous international standards.

The Unobstructed Access Advantage: How Cantilever Design Beats Conventional Racking

The fundamental flaw of traditional pallet racking is the vertical column. These front-facing posts create a barrier, making it difficult to slide long materials in and out. The Herochu Cantilever Rack eliminates this problem at its source. Its iconic design features a central upright column with sturdy arms that extend outwards, creating a completely clear, column-free storage bay.

This open architecture is a game-changer for material handling. It allows for instant accessibility to a single piece or a full load without any obstructions. Your forklift or overhead crane can approach from any angle, and your operators can easily handle unwieldy 20-foot bars or pipes without the frustrating dance of maneuvering around posts. Furthermore, the design permits uneven overhang, giving you the flexibility to store items of varying lengths without being constrained by fixed beam lengths. This system is the definitive solution for storing everything from structural steel and plumbing pipes to bar stock, lumber, and extrusions, finally allowing you to keep these essential items safely off the floor.

A Modular Ecosystem Built for Your Evolving Needs

A Herochu Cantilever Rack is not a static purchase; it’s a scalable storage ecosystem. The entire system is modular within its capacity series, meaning it grows and adapts as your business does. Start with a single-sided unit against a wall or opt for a double-sided unit that acts as a freestanding aisle. As your inventory changes, you can effortlessly expand by adding new uprights, arms, and brace sets. This modularity ensures you never need to abandon your initial investment. You can even interchange different arm lengths and styles on the same upright to create a custom configuration tailored to a diverse range of materials.

Engineered Components for Uncompromising Performance

The superiority of the Herochu system lies in the thoughtful engineering of its core components, each designed to address a specific storage challenge.

1. The Upright: The Unshakable Core

The upright column is the backbone of the entire system. Constructed from high-tensile steel, these uprights are available in varying heights and load capacities to form the foundation of your storage. The needed capacity is intelligently calculated by multiplying the number of arms per upright by the individual arm capacity, allowing for precise engineering. We offer models with both removable bases for ultimate flexibility and welded bases for maximum stability in permanent installations.

2. The Arm: Precision for Every Profile

The arms are where your materials rest, and Herochu provides specialized options to ensure security and accessibility.

-

Straight Arms: Ideal for materials that will not roll, such as lumber, square tubing, and solid bar stock. These arms are designed with a minimal pitch to compensate for deflection under load, ensuring a level storage surface.

-

Inclined Arms: Essential for storing cylindrical materials like metal or PVC pipes, tubes, and rollers. With a pitched design, these arms safely guide materials inward, preventing them from rolling off. For added security, optional stops or drop pins can be added.

A key principle to remember: arm capacity is inversely related to length. A shorter arm has a higher weight capacity, allowing you to mix and match arms on a single upright to handle both heavy, short bars and lighter, long pipes.

3. The Brace Set: The Framework of Stability

Stability is non-negotiable. Our heavy-duty brace sets, typically configured in an X-brace pattern, lock the uprights together to form a rigid, resilient structure. The required brace length is determined by the center-to-center distance of your uprights, which is itself dictated by the length of the materials you’re storing. This integrated bracing system ensures the entire rack remains stable, even when fully loaded.

Tangible Benefits That Transform Your Daily Operations

Implementing a Herochu Cantilever System delivers immediate and lasting returns:

-

Maximized Space & Order: Convert wasted aisle space into dense, vertical storage. Create a neat, orderly inventory system where every item has a designated, easily identifiable place.

-

Enhanced Safety: Eliminate the hazards of leaning piles and floor-based tripping. Keep heavy, long items securely stored at an accessible height.

-

Operational Efficiency: Enable fast, convenient handling with forklifts and cranes. Drastically reduce the time and labor required to locate and retrieve specific materials.

-

Total Flexibility: The modular design means your storage can evolve without costly replacements. Even the bases of the uprights can be used for additional storage of shorter items without subtracting from the rack’s main capacity.

Stop letting disorganized long materials dictate your workflow and compromise your safety. Contact a Herochu storage specialist today for a no-obligation consultation. Let us demonstrate how a customizable Cantilever Rack system for steel bar, tubing, and pipe can bring unparalleled organization, safety, and efficiency to your workshop.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever steel bar tubing & pipe storage racks

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Sheet Metal Storage Racks Solve Floor Space Problems

Read moreRated 0 out of 5