Heavy Duty Cantilever Racks & Lumber Racks for Sale

Walk into any metal-working shop and you will find the same bottleneck: I-beams sprawled across the floor, 6 m aluminum bars hiding behind a pallet of tubing, and the foreman pacing the aisle trying to locate the one length that matches today’s laser program. Herochu cantilever racks lift that clutter skyward, turn minutes of hunt-and-drag into seconds of crane-to-machine, and free enough floor space to park an extra CNC. The entry-level set starts at three grand, yet carries up to 42 t per tower without breaking eye contact.

Herochu Heavy-Duty Cantilever Racks

From $3,099 • CE / UE / ISO 9001 • Built for the way you really handle long stock

From $3,099 • CE / UE / ISO 9001 • Built for the way you really handle long stock

Walk into any metal-working shop and you will find the same bottleneck: I-beams sprawled across the floor, 6 m aluminum bars hiding behind a pallet of tubing, and the foreman pacing the aisle trying to locate the one length that matches today’s laser program. Herochu cantilever racks lift that clutter skyward, turn minutes of hunt-and-drag into seconds of crane-to-machine, and free enough floor space to park an extra CNC. The entry-level set starts at three grand, yet carries up to 42 t per tower without breaking eye contact.

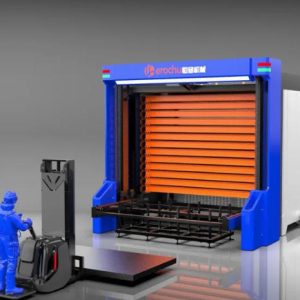

The frame is a welded fortress. 450 mm-deep I-beam columns are 100 % MIG-welded with hidden K-braces, so there are no bolt heads to snag crane slings. Arms telescope a full metre on sealed bearings rated for 5 t apiece, then lock positively when loaded. Push a pedal and every tier glides out like a machinist’s tool drawer, giving overhead cranes or vacuum lifters a clear shot at the exact bar, pipe or sheet bundle you need. No wider aisles, no fork-truck pirouettes, no manual prying with crowbars.

Steel is sold by the metre, but floor space is sold by the square. A single tower—only 1.2 m wide—stores 9 m lengths up to 4 m above the ground, reclaiming roughly 80 m² that used to be a tripping hazard. Add extra arms tomorrow; the upright is punched on 150 mm centres and the bolt pattern never changes. Lake-green columns and safety-orange arms give drivers high-visibility cues without looking like a toy, while a baked-on polyester powder survives the daily kiss of hot chips and welding spatter.

We list four pre-configured kits, yet most buyers mix and match. The HC-G6053S ships with three single-sided arms and handles 8 t total—perfect for a job shop that cuts 50 mm round bar on Fridays. The HC-G9055D doubles the height and loads 35 t, enough for a service center feeding three band-saws around the clock. Every spec you see—arm length, layer gap, loading per level—can be stretched or shrunk like metal clay. Need 12 m arms for wind-turbine towers? We weld them from the same I-beam stock and ship them bolt-on. Need 250 mm gaps for bronze rounds? We punch closer holes. The PLC brain stays identical across the range, so your maintenance crew learns once and services everything.

Control is refreshingly non-mystical. A frequency inverter soft-starts the arm drive, then holds position with electromagnetic brake—no hydraulics to leak, no air lines to freeze. A laser curtain across the face shuts travel instantly if a sleeve or sling intrudes. If you already run an overhead crane, the rack talks to it through a simple relay interlock: crane hoist raises, arm locks; arm extends, crane path clears. The HMI is a 4-inch colour pad mounted at eye level; it shows green when loaded, amber when extended, red if weight exceeds 5 200 kg. No passwords buried three menus deep, no Windows updates at 3 a.m.

Because long stock is rarely uniform, we offer three deck styles. Open arms let pipes overhang front and back, so you can mix 150 mm conduit with 600 mm CHS in the same bay. Flip-in steel bars create a solid shelf for bundles of flat bar or aluminum plate remnants. Optional galvanized wire mesh meets sprinkler codes when you store PVC-coated conduit or combustible pallets beside the steel rack. Every accessory bolts to the arm with a single M12 pin—change the config in minutes, not shifts.

Installation respects cash flow. The rack ships knock-down, stacked like lumber in a 40 ft container. Two fitters, one impact wrench and a spirit level assemble a 9 m tower before lunch. Anchor bolts are included; they bite 90 mm into level concrete and are certified for seismic zone 4. If you lease the building, specify our base-plate design that spreads load to 2 t per square metre—landlord smiles, permit closed. Should you move, undo the anchors, sleeve the holes, and truck the steel to the next plant; the asset travels with you, not with the real estate.

Buyers often pair the rack with a cheap hand-pushed bridge crane and immediately discover they can cut without a second operator. One Louisiana fabricator reported slashing material prep time 38 % the first month; the tower paid for itself in seven, then kept saving enough to finance a second laser the following year. A Dutch ship-yard stores 2 000 t of stainless pipe on eight linked towers, feeding plasma cutters that run lights-out. Their ERP downloads pick lists overnight; by morning the correct grades are extended, tagged and ready for robotic loading. Human intervention is limited to coffee.

The finish is chosen for resentment-free maintenance. Columns receive a two-coat lake-green polyester powder, baked at 200 °C for ten minutes, giving 80 µm of UV-stable skin that laughs at forklift bumps. Arms wear safety-orange so crane drivers see contrast against gray steel stock. Welds are ground smooth before coating, eliminating dirt traps that invite rust streaks. After five years outdoors the color is still recognizable; after ten you might decide to pressure-wash, not repaint.

We keep replacement parts boringly standard. Arms use 6204 sealed bearings, same as conveyor rollers worldwide. The locking pin is a common clevis with an R-clip—lose one, buy another at a tractor store. The inverter is an off-the-shelf Hitachi drive stocked on every continent. Your maintenance team will never hunt a proprietary circuit board or wait six weeks for a special beam extrusion. If you can service a pallet rack, you already know how to keep Herochu alive.

Ordering is equally blunt. Email a hand sketch or a professional floor plan, list the longest and heaviest piece you own, and state how many different profiles you cut per week. We return a 3D STEP file, a loading diagram, and a fixed price that includes freight to your dock—no “allowances,” no surprise fuel surcharge when the ship hits port. A 30 % deposit locks production; balance is due after video acceptance from our factory. Delivery averages 25 calendar days to North America, 20 to the EU, 30 to Australia. Every tower leaves the plant with a serial plate and a digital birth certificate: material grade, weld map, load test certificate, and coating thickness report. Your insurer receives the file before the steel even sails.

The rack you buy today can grow sideways tomorrow. Starter bays accept add-on modules with nothing more than four bolts and a splice plate. Expand left, right, or back-to-back; arms can be single- or double-sided; columns can stand indoors or under a canopy. Whether you store 50 mm brass rod, 400 mm aluminum I-beams, or plastic-wrapped bundles of composite decking, the same skeleton handles the lot. Your capital request this year covers only what you need right now, yet the architecture is already hungry for the next surge in business.

Long material never gets shorter, but the space you devote to it can shrink. Herochu cantilever racks trade vertical air—cheap, abundant, tax-free—for the expensive horizontal real estate you are currently walking around. The math is simple: one square metre of floor, four metres of height, forty tonnes of stock, one operator, seventy seconds, zero drama. When you are ready to stop tripping over your own inventory, we will be ready to ship the steel that lifts it safely into the sky.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Telescopic Cantilever Racking Systems For Aluminium Profiles

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Telescopic Cantilever Storage Rack for Efficient Long-Load Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racks & Lumber Racks for Sale

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & used heavy duty cantilever racks for sale

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Heavy Duty Plate Storage Warehouse

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automated Plate Warehouse with High Load Capacity

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5