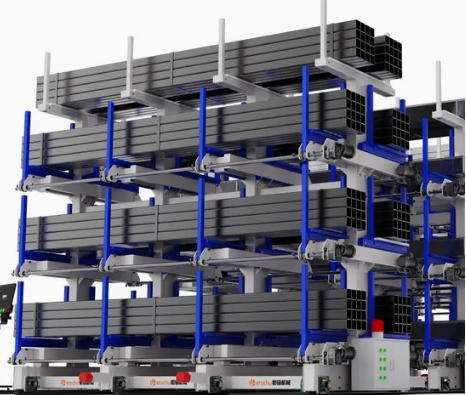

Heavy duty cantilever sheet metal rack

Herochu’s Heavy Duty Cantilever Sheet Metal Rack was built to fix this exact problem. Designed for unobstructed storage of long, bulky materials like sheet metal, lumber, and construction steel, this system turns chaos into order—with customizable configurations, industrial-grade durability, and global certifications (CE, UE, ISO 9001) that guarantee it stands up to even the toughest factory demands.

Herochu Heavy Duty Cantilever Sheet Metal Rack: Solve Bulky Storage Headaches, Starting at $5,000

If your warehouse or workshop is struggling with long, awkward sheet metal pieces—stacked haphazardly against walls, taking up valuable floor space, or risking damage when loaded/unloaded—you’re not just wasting time. You’re putting your team’s safety and your inventory’s integrity at risk. Herochu’s Heavy Duty Cantilever Sheet Metal Rack was built to fix this exact problem. Designed for unobstructed storage of long, bulky materials like sheet metal, lumber, and construction steel, this system turns chaos into order—with customizable configurations, industrial-grade durability, and global certifications (CE, UE, ISO 9001) that guarantee it stands up to even the toughest factory demands.

What Makes a Cantilever Rack the Right Choice for Sheet Metal?

Traditional pallet racks or vertical storage units work for small, uniform items—but sheet metal? It’s long, often heavy, and needs space to be accessed without bending, scratching, or denting. Cantilever racks solve this by ditching vertical uprights in the storage area: instead, sturdy horizontal arms extend from a central column, creating a clear, open space to hold even the longest sheets. For sheet metal operations, this design isn’t just convenient—it’s transformative.

Imagine loading a 12-foot sheet of steel with a forklift: no vertical bars to maneuver around, no need to angle the load to fit. With Herochu’s cantilever rack, you drive straight in, set the sheet on the arms, and move on. Unloading is just as easy—no digging through stacked materials or risking injury from shifting loads. And because there are no obstructions, every sheet is visible at a glance—so your team never wastes time hunting for the right material.

But this isn’t a “one-light-duty-use” rack. Herochu’s heavy duty model is built with either roll-formed or structural steel—choosing structural steel means you’re getting a system that handles tons of weight without sagging. Whether you’re storing thin aluminum sheets or thick-gauge steel plates, this rack keeps your inventory secure, organized, and accessible.

Herochu’s Standard Cantilever Rack Models: Built for Power and Versatility

Herochu offers eight standard models, each engineered for specific load capacities, sheet lengths, and workshop needs. From 6-foot sheets to 12-foot behemoths, and from 2-ton per-layer loads to 6-ton heavyweights, there’s a standard model that fits most industrial use cases—no customization required. Let’s break down the key specs so you can find the right fit:

Single-Sided vs. Double-Sided: Maximize Space Based on Your Layout

- Single-Sided Models: Ideal for against-the-wall placement, these racks use one column with arms extending in one direction. Perfect for workshops with limited width or where you want to keep walkways clear.

- Double-Sided Models: Arms extend from both sides of the column, doubling storage capacity in the same floor space. Great for open warehouse areas where you can access the rack from two sides.

Model Breakdown: Capacity, Size, and Use Cases

|

Model

|

Storage Sheet Length

|

Per-Layer Load

|

Total Rack Load

|

Number of Layers

|

Arm Length

|

Distance Between Layers

|

Best For

|

|

HC-G6053S

|

6000mm (19.69ft)

|

2tons

|

8tons

|

3+1

|

550mm

|

600mm

|

Small to mid-sized shops storing 6ft sheets (e.g., HVAC ductwork, small steel plates). Single-sided for wall placement.

|

|

HC-G6053D

|

6000mm (19.69ft)

|

3tons

|

25tons

|

4+1

|

600mm

|

600mm

|

Busy factories handling heavier 6ft sheets (e.g., automotive frames, construction brackets). Double-sided for high-density storage.

|

|

HC-G9055S

|

9000mm (29.53ft)

|

5tons

|

35tons

|

3+1

|

800mm

|

800mm

|

Heavy-duty operations with 9ft sheets (e.g., structural steel, large aluminum panels). Single-sided for tight spaces.

|

|

HC-G9055D

|

12000mm (39.37ft)

|

6tons

|

42tons

|

3+1

|

800mm

|

800mm

|

Industrial facilities storing extra-long 12ft sheets (e.g., shipbuilding parts, large construction beams). Double-sided for maximum capacity.

|

|

HC-B3015-63

|

3000x1500mm (9.84×4.92ft)

|

3tons

|

Customizable

|

5+1

|

Custom

|

Specialty shops needing smaller, precise storage (e.g., custom metal fabrication, electronics components).

|

|

|

HC-B4015-63

|

4000x1500mm (13.12×4.92ft)

|

3tons

|

Customizable

|

5+1

|

Custom

|

Custom

|

Mid-sized operations with 13ft sheets (e.g., roofing panels, industrial shelving materials).

|

|

HC-B4020-65

|

4000x2000mm (13.12×6.56ft)

|

3tons

|

Customizable

|

5+1

|

Custom

|

Custom

|

Factories storing wide 13×6.5ft sheets (e.g., large machinery parts, architectural metal).

|

|

HC-B6020-66

|

6000x2000mm (19.69×6.56ft)

|

3tons

|

Customizable

|

5+1

|

Custom

|

Custom

|

Heavy-use shops with 19.69×6.56ft sheets (e.g., commercial construction steel, large-scale fabrication projects).

|

Every standard model shares core features that make Herochu a leader in cantilever storage:

- Adjustable Arms: Move arms up or down to fit different sheet thicknesses—no tools required for quick adjustments.

- Forklift-Friendly Design: Smooth arm surfaces and open access mean forklifts, cranes, or hoists can load/unload without damaging the rack or sheets.

- High-Visibility Storage: No vertical bars block your view, so you can quickly check inventory levels and find materials.

- Powder-Coated Steel: Resists rust, scratches, and industrial wear—perfect for factories with dust, moisture, or heavy foot traffic.

Customization: Build a Rack That Fits Your Workshop Like a Glove

Not every workshop has “standard” needs. Maybe you store extra-thick sheet metal that requires wider arms. Or your warehouse has low ceilings that demand shorter racks. Herochu’s custom cantilever rack option lets you design a system that checks every box—no compromises. Our customization process is simple: we start by understanding your workflow, then tailor every component to your exact requirements.

Key Customization Options:

- Load Capacity: Need to handle more than 6 tons per layer? We reinforce arms and columns with thicker structural steel to support heavyweights—ideal for foundries or heavy machinery manufacturers.

- Sheet Size: Whether you need to store 15-foot specialty sheets or small 2-foot remnants, we adjust arm length and rack width to fit. No more cutting sheets to fit a rack—your rack fits your sheets.

- Number of Layers: Choose from 2+1 up to 10+1 layers (the “+1” refers to a top shelf for small remnants). More layers mean maximum vertical storage; fewer layers mean easier access for frequently used materials.

- Arm Design: Pick straight arms for flat sheets or inclined arms for cylindrical materials (like pipes or tubes—yes, this rack works for more than just sheet metal!).

- Color: Match your rack to your workshop’s safety standards (e.g., red for high-traffic areas, yellow for hazard zones) or brand colors. Our powder-coat finish comes in any shade you need.

- Accessories: Add label holders to track inventory, safety stops to prevent sheets from sliding off, or rubber arm pads to protect delicate materials (like aluminum or polished steel).

One recent customer—a large construction firm—needed a custom rack to store 14-foot steel beams and 8-foot sheet metal side-by-side. We designed a double-sided rack with adjustable arms: longer arms on one side for the beams, shorter arms on the other for the sheets. The result? They cut their storage footprint by 40% and reduced loading time by 25%. That’s the power of a custom Herochu rack.

How to Design Your Cantilever Rack: Herochu’s Expert Tips

Designing a cantilever rack isn’t just about picking a model—it’s about making sure it works with your existing space and workflow. Here’s how we help you get it right:

1. Calculate Capacities (Don’t Guess!)

- Upright Capacity: Multiply the weight of materials on each arm level by the number of levels. For example, if you have 4 levels with 3 tons each, your uprights need to handle 12 tons total.

- Arm Capacity: Divide the total weight of one layer by the number of arms supporting it. If a 6-ton sheet is on 3 arms, each arm needs to hold 2 tons. This ensures even weight distribution—no sagging or breaking.

2. Get Column Spacing Right

The distance between columns matters. For most sheet metal, the gap between columns should be half the length of your longest sheet. So, if you’re storing 12-foot sheets, space columns 6 feet apart—this leaves 3 feet hanging over each end, preventing “load deflection” (sagging) that can damage sheets or make the rack unsafe.

3. Consider Your Warehouse Layout

Our design team will ask for details like:

- Warehouse dimensions (length, width, ceiling height)

- Where forklifts or cranes operate (to avoid blocking paths)

- How often you access different materials (frequently used sheets go on lower, easier-to-reach levels)

- Future growth (we design racks that can be expanded later if you need more storage)

We don’t just sell you a rack—we help you build a storage system that grows with your business.

Why Herochu? Certifications, Durability, and Service You Can Trust

When you buy a heavy duty cantilever rack, you’re investing in years of use. Herochu doesn’t cut corners on quality:

- CE, UE, ISO 9001 Certified: Our racks meet strict global standards for safety and performance. Whether you’re in the U.S., Europe, or Asia, you can trust your Herochu rack is compliant.

- Structural Steel Options: For the heaviest loads, our structural steel racks are welded and reinforced to handle constant use. They won’t bend, rust, or fail—even in harsh industrial environments.

- End-to-End Support: From design to installation, we’re with you every step. We ship racks with a steel bottom support to prevent damage in transit, and our team can arrange professional installation (for an extra fee) to ensure everything is set up safely.

- After-Sales Care: If you need replacement parts, adjustments, or maintenance, our customer service team is available 24/7. We stand behind our products—if something goes wrong, we fix it.

Who Benefits From Herochu’s Heavy Duty Cantilever Rack?

This rack isn’t just for sheet metal shops—it’s for any business that struggles with long, bulky materials:

- Metal Fabricators: Store full sheets, remnants, and custom cuts without damage.

- Construction Companies: Keep steel beams, roofing panels, and lumber organized on-site.

- Automotive Manufacturers: Store large body panels, frames, and chassis parts safely.

- Aerospace Suppliers: Handle delicate (but long) aluminum sheets with care.

- Warehouses: Maximize storage density for long materials without wasting floor space.

Start Your Custom Storage Journey for $5,000 and Up

Herochu’s Heavy Duty Cantilever Sheet Metal Rack starts at $5,000 for standard models—an investment that pays off in faster workflows, less waste, and safer operations. Custom models are priced based on your specs, but we work with businesses of all sizes to find a solution that fits their budget.

Ready to stop struggling with disorganized sheet metal? Contact Herochu today to:

- Chat with our design team about your storage needs (no technical jargon required—we speak “workshop”).

- Get a free quote for standard or custom racks.

- Schedule a virtual tour of our manufacturing facility to see how we build durable racks.

Don’t let bulky materials slow you down. Herochu’s cantilever rack turns chaos into order—so you can focus on what you do best: making great products.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Heavy duty cantilever sheet metal rack

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Vertical Sheet Metal Rack Storage Systems Provider

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Residual material rack for vertical sheet metal storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Electric automatic telescopic cantilever shelf

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industrial Sheet Metal Rack Electric Telescoping Cantilever Pipe Warehouse Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Warehouse Cantilever Rack Storage System

Read moreRated 0 out of 5