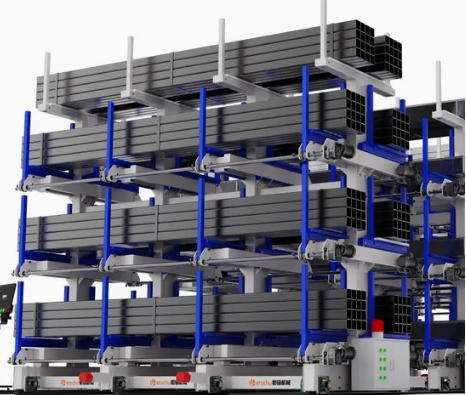

Industrial Roll-out Telescopic Cantilever Rack

Herochu doesn’t believe in “one-size-fits-all” storage. That’s why we offer four rugged standard models—HC-G6053S, HC-G6053D, HC-G9055S, and HC-G9055D—each tailored to handle different steel profile sizes, weights, and volumes. And if your needs fall outside the standard, our fully customizable option lets you design a rack that fits your exact specifications, from storage sheet size to total loading capacity.

Herochu Heavy Duty Storage Racks for Steel Profiles: Built to Solve Your Toughest Industrial Storage Challenges

For manufacturers, distributors, and fabricators working with steel profiles—long, bulky, and often heavy materials—storage has always been a balancing act. Lean them against walls, and you risk damage or tip-overs. Stack them on the floor, and you waste space, slow down retrieval, and create safety hazards. Herochu’s Heavy Duty Storage Racks for Steel Profiles are engineered to end this struggle. Designed for durability, flexibility, and efficiency, these racks transform chaotic storage areas into organized, high-performing hubs—all while meeting global quality standards with CE, UE, and ISO 9001 certifications. Starting at just $3,099 and fully customizable to your workshop’s unique needs, they’re not just storage—they’re a strategic tool to boost productivity, cut costs, and keep your team safe.

Choose the Right Rack for Your Steel Profile Needs: Standard Models & Custom Options

Herochu doesn’t believe in “one-size-fits-all” storage. That’s why we offer four rugged standard models—HC-G6053S, HC-G6053D, HC-G9055S, and HC-G9055D—each tailored to handle different steel profile sizes, weights, and volumes. And if your needs fall outside the standard, our fully customizable option lets you design a rack that fits your exact specifications, from storage sheet size to total loading capacity.

Let’s break down the details that matter:

- HC-G6053S: Ideal for smaller steel profiles, this single-sided rack accommodates 6000mm sheets, supports 2 tons per layer, and offers 3+1 layers for a total loading capacity of 8 tons. With 550mm arm length and 600mm distance between layers, it’s compact yet powerful—perfect for workshops with limited space.

- HC-G6053D: Step up to double-sided storage with the HC-G6053D. It handles the same 6000mm sheets but boosts per-layer loading to 3 tons and layers to 4+1, delivering a massive 25 tons of total capacity. At 600mm arm length, it maximizes vertical space without sacrificing accessibility.

- HC-G9055S: For longer steel profiles (up to 9000mm), the HC-G9055S is a double-sided workhorse. It supports 5 tons per layer across 3+1 layers, totaling 35 tons, with 800mm arms and 800mm layer spacing—built to handle heavy, extended materials with ease.

- HC-G9055D: Our most robust standard model, the HC-G9055D, takes on 12000mm steel profiles, 6 tons per layer, and 3+1 layers for a staggering 42 tons of total loading. With 800mm arms and layer spacing, it’s designed for high-volume, heavy-duty industrial use.

- Customized: Need a rack for non-standard sheet sizes, unique weight requirements, or a specific workshop layout? Our customization option lets you adjust every detail—from sheet length and per-layer loading to arm length, layer count, and even color (beyond our standard orange/blue). Whatever your steel profile storage needs, we’ll build a rack that fits.

Every model comes equipped with a PLC frequency conversion control system—a game-changer for efficiency. This automated system streamlines material handling, reducing manual effort and ensuring smooth, precise operation. Whether you’re loading, unloading, or adjusting the rack, the PLC control makes the process faster and more reliable, cutting down on downtime and operator fatigue.

Efficient Space Use: Turn Wasted Vertical Space into Productive Storage

The biggest pain point for most workshops storing steel profiles is wasted space. Long materials often force teams to use floor space horizontally, leaving valuable vertical space unused. Herochu’s Heavy Duty Storage Racks flip this script by prioritizing vertical storage—turning empty overhead areas into high-capacity storage zones.

Take the HC-G9055D, for example: with 3+1 layers and 800mm spacing between them, it stores 12000mm steel profiles vertically, freeing up floor space that would otherwise be occupied by sprawling piles. Imagine what you could do with that extra room: add a new fabrication machine, expand your assembly line, or create clearer walkways for your team. For small to large facilities alike, this space reclamation isn’t just a convenience—it’s a way to grow your operations without expanding your workshop’s footprint.

Our roll-out and cantilever-inspired design (seen in models like the HC-G6053D) takes this a step further. By using adjustable arms and easy-access slots, we ensure every steel profile is within reach—no more climbing over piles or struggling to reach materials at the back of a shelf. This design also eliminates the need for bulky pallets or temporary supports, keeping your floor clear and your workflow unobstructed.

Adjustable, Flexible, and Ready to Grow with Your Business

Steel profile inventory changes—whether you’re taking on larger projects, adding new materials, or scaling production. Herochu’s racks are built to adapt. The adjustable arms and layer heights (600mm or 800mm, with custom options available) let you reconfigure the rack as your needs shift. Need to store thicker profiles? Increase the layer spacing. Adding a new steel profile size? Adjust the arm length. This flexibility means your rack won’t become obsolete as your business grows—it will evolve with it.

The bolt-together construction of every model makes adjustments and expansions easy. Unlike welded racks that are fixed in place, our design lets you add layers, extend arms, or even reposition the rack in your workshop with minimal effort. For distributors who handle seasonal inventory spikes or manufacturers who take on custom orders, this adaptability is invaluable. You won’t need to invest in a new rack every time your storage needs change—just modify the one you have.

Heavy-Duty Capacity: Safety and Strength You Can Trust

Steel profiles are heavy—there’s no getting around it. A single 12000mm steel beam can weigh thousands of pounds, and storing it improperly puts your team and materials at risk. Herochu’s Heavy Duty Storage Racks are engineered to handle this weight with zero compromise on safety.

Each model is built with high-grade steel frames and reinforced arms, tested to exceed their listed load capacities. The HC-G9055D, for instance, is rated for 42 tons total—more than enough to handle even the heaviest industrial steel profiles. The PLC frequency conversion control system adds another layer of safety by ensuring smooth, controlled movement—no sudden jolts or shifts that could damage materials or injure workers.

We also prioritize visibility and organization to reduce accidents. By storing steel profiles vertically and in clearly defined slots, your team can see every material at a glance. No more rummaging through piles, moving heavy items to reach what’s behind them, or guessing where a specific profile is stored. This organization cuts down on trip hazards, material damage, and the risk of strains from manual lifting—creating a safer workplace for everyone.

Time Optimization: Spend Less Time on Storage, More Time on Production

Every minute your team spends searching for a steel profile, adjusting a unstable stack, or struggling to load materials is a minute lost to productive work. Herochu’s racks are designed to eliminate these delays.

The PLC frequency conversion control system automates much of the material handling process. Loading a 6-ton steel profile onto the HC-G9055D? The system moves the arm into place smoothly, reducing the time it takes to secure the material. Retrieving a 6000mm profile from the HC-G6053S? The adjustable arms slide out, putting the profile within easy reach—no more climbing ladders or using cranes to reach high shelves.

The organized storage layout also speeds up inventory checks. With each steel profile stored in a designated slot, your team can do a quick visual count to confirm stock levels—no more manually weighing or measuring materials. This saves hours of time each week, letting you focus on what matters: fabricating, assembling, and delivering orders.

For plastic industry manufacturers or distributors who also handle PVC pipes or tubing (a common complement to steel profiles), these racks offer added value. The adjustable slots and arms can be reconfigured to store PVC materials alongside steel profiles, creating a unified storage system that reduces clutter and simplifies workflow. Why invest in separate racks for different materials when one Herochu system can handle it all?

Why Herochu? Quality, Certifications, and a Focus on Your Success

There are plenty of storage racks on the market, but Herochu stands out for our commitment to quality and customer-centric design. Our CE, UE, and ISO 9001 certifications aren’t just labels—they’re proof that every rack we build meets the strictest global standards for safety, durability, and performance. When you buy a Herochu Heavy Duty Storage Rack for Steel Profiles, you’re buying a product that’s been tested, validated, and built to last.

We also understand that every workshop is different. That’s why we offer customization beyond just specs—we work with you to understand your workflow, space constraints, and long-term goals. Whether you’re a small fabricator with a 500-square-foot shop or a large distributor with a 10,000-square-foot warehouse, we’ll design a storage solution that fits your needs and budget.

And with a starting price of $3,099, our racks are an affordable investment in your business’s future. The time saved on retrieval, the space reclaimed for production, and the reduction in material damage will pay for the rack in months—not years. For example, a mid-sized steel fabricator using the HC-G6053D reported cutting storage-related labor costs by 30% and reducing material waste by 25% in the first year alone. That’s real savings that add up to a stronger bottom line.

Get Started with Herochu: Transform Your Steel Profile Storage Today

Your workshop deserves a storage solution that works as hard as your team. Herochu’s Heavy Duty Storage Racks for Steel Profiles—certified, customizable, and built for strength—are the answer. Whether you need a standard model like the HC-G9055S or a fully customized system, we’ll help you design a rack that optimizes space, enhances safety, and boosts productivity.

Don’t let disorganized, inefficient storage hold your business back. Contact our team today to discuss your steel profile storage needs. We’ll provide a free consultation, share detailed specs for our standard models, and help you create a custom solution that fits your workshop perfectly. With Herochu, you’re not just buying a rack—you’re investing in a more efficient, safer, and more profitable operation.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industrial Roll-out Telescopic Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Storage solution for long timber packs

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty Storage racks for steel profiles

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Storage steel sheets racks measuring 1500×3000 or 3500mm for 3t sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Optimizing Warehouse Efficiency with Pipe Racking systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industry Pipe Storage and Racking Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5