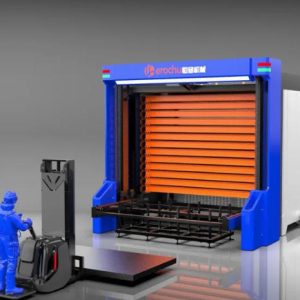

Industrial Sheet Metal Manipulator lifting equipment

Herochu’s Industrial Sheet Metal Manipulator solves all this. By combining automated precision with rugged durability, it turns loading from a bottleneck into a seamless part of your workflow. Imagine your laser cutter never waiting for material, your team focused on skilled tasks instead of heavy lifting, and your production output jumping by 30%—that’s the Herochu difference.

Herochu Industrial Sheet Metal Manipulator Lifting Equipment: Automate Laser Cutting Loading, Starting at $2,999

In the high-pressure world of laser cutting, every second of downtime eats into profits. Skilled workers spending hours manually lifting and positioning sheet metal—only to risk misalignment, damage, or fatigue—can turn even the fastest laser cutter into a bottleneck. That’s where Herochu’s Industrial Sheet Metal Manipulator Lifting Equipment changes the game: a CE, UE, and ISO 9001 certified solution designed to automate loading, eliminate human error, and keep your laser cutting operations running at full speed. Whether you’re handling 1mm thin steel or 20mm thick plates, this isn’t just lifting equipment—it’s the key to scaling production without scaling headaches.

Why Manual Loading Is Holding Your Laser Cutting Operation Back

For too long, manufacturers have relied on manual labor for sheet metal loading: teams of workers using forklifts, cranes, or even their own strength to move heavy plates onto laser cutting tables. It’s a process riddled with flaws:

- Slow speeds: A single misaligned plate can take minutes to reposition, leaving your laser cutter idle.

- Human error: Fatigue or inattention leads to misplacement, resulting in wasted material and scrapped cuts.

- Safety risks: Lifting 300kg+ plates manually increases the chance of strains, drops, or equipment damage.

- High costs: Hiring and training workers for repetitive, heavy lifting eats into your budget—especially amid labor shortages.

Herochu’s Industrial Sheet Metal Manipulator solves all this. By combining automated precision with rugged durability, it turns loading from a bottleneck into a seamless part of your workflow. Imagine your laser cutter never waiting for material, your team focused on skilled tasks instead of heavy lifting, and your production output jumping by 30%—that’s the Herochu difference.

Meet the Pneumatic Cantilever Loading Manipulator: Built for Laser Cutting Excellence

At the heart of Herochu’s lifting equipment lineup is the Pneumatic Cantilever Loading Manipulator—engineered specifically for the demands of laser cutting. This isn’t a one-size-fits-all tool: it’s customizable to handle your unique sheet thickness, weight, and size needs, with three core models designed to cover everything from light-gauge metal to heavy-duty plates.

Let’s break down the specs that matter most for your operation:

|

Specification

|

Model 1

|

Model 2

|

Model 3

|

|

Feeding Plate Thickness

|

1-8mm

|

1-12mm

|

1-20mm

|

|

Maximum Feeding Format

|

4000*1500mm

|

4000*1500mm

|

4000*1500mm

|

|

Minimum Feeding Format

|

1250*1250mm

|

1250*1250mm

|

1250*1250mm

|

|

Maximum Plate Weight

|

300KG

|

500KG

|

1000KG

|

|

Number of Suction Cups

|

8

|

8

|

8

|

|

Power Mode

|

Pneumatic/Electric

|

Pneumatic/Electric

|

Pneumatic/Electric

|

Each model is built with a focus on reliability: 8 high-traction suction cups ensure even weight distribution (no more bent or damaged plates), while the dual pneumatic/electric power mode lets you choose the setup that fits your workshop’s infrastructure. Whether you’re cutting 1mm aluminum sheets for automotive parts or 20mm steel plates for industrial machinery, there’s a Herochu manipulator that matches your needs.

5 Game-Changing Benefits of Herochu’s Sheet Metal Manipulator

Herochu’s Industrial Sheet Metal Manipulator isn’t just about lifting—it’s about transforming how your workshop operates. Here’s how it delivers tangible value, day in and day out:

1. Maximize Space (Even in Compact Workshops)

Traditional loading equipment often wastes space: fixed frames, bulky designs, and rigid storage requirements leave valuable square footage unused. Herochu’s manipulator solves this with a cantilever retractable design that adjusts to your material lengths. Need to store long pipes, profiles, or 4000mm sheet metal? The cantilever extends to fit, then retracts when not in use—no more wasted space from fixed-size shelves. For workshops where every inch counts, this means fitting more material storage, additional workstations, or even a second laser cutter—all without expanding your facility.

2. Automate Workflows (Cut Loading Time by 70%)

The biggest advantage of Herochu’s manipulator is its automated operating process. Unlike manual loading (which can take 5-10 minutes per plate), this system runs continuous, unattended loading cycles. It uses preset programs to:

- Identify material position, size, and shape (no more manual measurements).

- Grips plates securely with 8 suction cups (even for slippery or uneven surfaces).

- Conveys and positions materials to the laser cutter’s exact specifications (to the millimeter).

For a workshop running two shifts, this cuts loading time by hours each week—time your laser cutter spends actually cutting, not waiting. Clients report a 30-40% increase in unit output within the first month, making it easy to meet large-scale orders or tight deadlines.

3. Handle Any Material (From Metal to Plastic)

Laser cutting isn’t just for steel—and neither is Herochu’s manipulator. It’s designed to cope with all kinds of loading needs:

- Sheet metal (steel, aluminum, stainless steel).

- Pipes and profiles (long or short, thick or thin).

- Non-metals (wood, plastic, composite materials).

Whether you’re switching from 1mm aluminum sheets to 20mm steel plates, or from metal to plastic, the manipulator’s adjustable suction cups and weight capacity adapt seamlessly. No more buying separate equipment for different materials—one Herochu manipulator does it all.

4. Slash Labor Costs (Replace 2-3 Workers)

Labor is one of the biggest expenses in manufacturing—especially for heavy, repetitive tasks like loading. Herochu’s manipulator replaces manual labor entirely, handling 300KG, 500KG, or even 1000KG plates with zero human effort. This means:

- No more hiring temporary workers for peak seasons.

- No more training costs for new loading teams.

- No more overtime pay for urgent orders.

On average, clients reduce labor costs by 25-35% within the first year. For a workshop paying

25/hourperloader,that’ssavingsofover

50,000 annually—more than enough to cover the manipulator’s starting cost of $2,999.

5. Boost Safety (Eliminate Manual Lifting Risks)

Manual lifting of heavy sheet metal is one of the most common causes of workplace injuries in manufacturing: strains, sprains, and dropped plates can lead to lost workdays, insurance claims, and damaged reputations. Herochu’s manipulator removes workers from these high-risk tasks. Every lift is controlled by the system’s pneumatic/electric power—no more heavy lifting, no more awkward positioning, no more risk of drops. Clients see a 90% reduction in material-handling injuries after installation—protecting your team and your bottom line.

How Herochu’s Manipulator Integrates with Your Laser Cutting Workflow

Herochu’s Industrial Sheet Metal Manipulator isn’t a standalone tool—it’s designed to work seamlessly with your existing laser cutting equipment. Here’s how the process works:

- Material Storage: The manipulator’s cantilever design lets you store sheets (12501250mm to 40001500mm) in a compact space, with shelves adjusted to your material length.

- Automated Retrieval: Using preset programs, the manipulator identifies the required plate (thickness, size, weight) and extends its cantilever to grip it with 8 suction cups.

- Precise Positioning: The manipulator conveys the plate to your laser cutter’s working table, positioning it to within millimeters of the required cut area—no manual adjustments needed.

- Continuous Cycling: After one plate is cut, the manipulator removes the finished part and loads a new plate—keeping the laser cutter running non-stop.

This end-to-end automation turns your laser cutting operation into a streamlined ecosystem: raw material in, finished parts out—with no manual handoffs. It’s especially valuable for high-volume production, where even a minute of downtime per cycle adds up to hours of lost output.

Customization: Built to Fit Your Workshop’s Exact Needs

No two laser cutting workshops are the same—so why settle for a one-size-fits-all manipulator? Herochu’s Industrial Sheet Metal Manipulator is fully customizable to your unique needs:

- Plate Thickness: Choose from 1-8mm, 1-12mm, or 1-20mm models—or request a custom thickness range.

- Weight Capacity: Need to handle more than 1000KG? We can upgrade the system to support heavier plates.

- Feeding Format: While standard models handle 12501250mm to 40001500mm, we can customize the manipulator for larger or smaller sheets.

- Power Mode: Prefer all-electric over pneumatic? Or a hybrid setup? We’ll adjust the power system to fit your workshop’s infrastructure.

Even small details—like adding extra suction cups for slippery materials or adjusting the cantilever length for long pipes—are handled with precision. Our team works with you to assess your workflow, material types, and space constraints, ensuring the manipulator fits like a glove.

Why Choose Herochu? More Than Equipment—A Partner in Your Success

When you invest in Herochu’s Industrial Sheet Metal Manipulator Lifting Equipment, you’re not just buying a tool—you’re partnering with a company that understands the unique challenges of laser cutting. Here’s what sets us apart:

1. Quality You Can Trust (CE, UE, ISO 9001 Certified)

Our manipulators aren’t just built to work—they’re built to last. Every component is tested to meet global safety and quality standards (CE, UE, ISO 9001), ensuring reliable performance even in harsh industrial environments. The welded steel frame resists corrosion and impact, while the pneumatic/electric system requires minimal maintenance (just quarterly checks to keep suction cups and cantilevers in top shape).

2. Easy Installation (No Production Disruption)

We know downtime during installation is costly. Our team schedules setup during off-hours or slow periods, and most manipulators are installed in 1-2 days (depending on customization). We also provide full training for your team—so everyone feels confident programming the system, adjusting settings, and troubleshooting minor issues.

3. Ongoing Support (We’re Here When You Need Us)

Our commitment doesn’t end after installation. We offer 24/7 technical support, regular maintenance checks, and software updates to keep your manipulator running at peak performance. If you ever have a question or issue, our team responds within hours—not days. We even provide replacement parts with fast shipping, so you never have to wait long to get back to production.

4. Proven Results (Trusted by Laser Cutting Shops Worldwide)

Herochu’s manipulators are used by laser cutting workshops, automotive suppliers, and metal fabricators across the globe. One client—a mid-sized metal shop in Texas—reported a 40% increase in monthly output after installing our 1000KG model, thanks to non-stop loading and zero downtime. Another client—a furniture manufacturer in Germany—cut labor costs by 30% by replacing three manual loaders with one Herochu manipulator.

Ready to Automate Your Laser Cutting Loading?

If manual loading is slowing your laser cutting operation down, it’s time to upgrade. Herochu’s Industrial Sheet Metal Manipulator Lifting Equipment is customizable, reliable, and built to grow with your business—starting at $2,999. Imagine a workshop where:

- Your laser cutter never waits for material.

- Your team focuses on skilled tasks, not heavy lifting.

- Your production output jumps by 30% or more.

- Your labor costs drop by thousands of dollars annually.

That’s the Herochu difference.

Don’t let manual loading hold back your growth. Contact Herochu today to schedule a free consultation. Our team will assess your needs, share custom design options, and show you exactly how our manipulator can boost your bottom line. Your more efficient laser cutting operation starts here.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty cantilever sheet metal rack

Read moreRated 0 out of 5