For warehouses, manufacturing plants, and construction sites, storing pipes, bars, and tubing has always been a logistical headache. Long, bulky, and easily damaged, these materials often end up in disorganized piles on the floor—wasting space, risking injury, and slowing down operations. If you’re tired of hunting for the right pipe in a chaotic stack, dealing with bent or scratched inventory, or watching valuable floor space get swallowed by unruly long materials, it’s time to invest in a solution that’s built for your needs. Herochu’s Industry Pipe Storage and Racking Solutions are engineered to optimize organization, enhance safety, and maximize space—all while being fully customizable to your workshop. Starting at $3,099 and backed by CE, UE, and ISO 9001 certifications, our heavy-duty racks turn long material storage from a bottleneck into a streamlined asset.

The Hidden Costs of Disorganized Long Material Storage

Floor-stacked pipes and bars might seem like a “no-cost” solution, but they come with a hidden price tag that eats into your bottom line. Let’s break down the ways unorganized storage harms your operation:

1. Wasted Space That Limits Growth

Long materials take up massive amounts of floor space when stored horizontally. A single stack of 20-foot pipes can occupy 100+ square feet—space that could be used for additional inventory, production equipment, or workflow expansion. For a 10,000-square-foot warehouse, this means losing up to 30% of your usable area to inefficient storage. Expanding your facility to compensate would cost hundreds of thousands of dollars in construction and relocation fees, but the right racking system can unlock that space instantly—no renovation required.

2. Costly Material Damage

Pipes and tubing are delicate when mishandled. Scratches, dents, or bends from floor stacking don’t just ruin aesthetics—they render materials unusable for precision projects. A single damaged stainless steel pipe can cost

200, and over time, these losses add up: the average facility wastes 8-12% of its long material budget due to improper storage. For a company spending

200,000annuallyonpipesandbars,that’s

16,000-$24,000 in avoidable scrap—money that could be reinvested in tools, training, or new projects.

3. Safety Risks That Threaten Your Team and Budget

Unstable piles of pipes are a disaster waiting to happen. A single falling pipe can cause crush injuries, lacerations, or even permanent harm to your employees. The average workplace injury involving heavy materials costs

60,000+inmedicalbills,workercompensation,andlegalfees—nottomentiontheintangiblecostsoflostmoraleanddamagedreputation.Additionally,OSHAfinesforunsafestoragepracticescanreach

136,000 per violation, putting your business at risk of financial ruin.

4. Productivity Loss From “Material Hunts”

When pipes are stacked haphazardly, finding the right length or diameter becomes a time-consuming chore. Employees spend hours moving heavy materials to access the one they need, while production lines sit idle. For a facility with 10 workers earning

25/hour,thiswastedtimecosts

500+ per day—or $125,000 annually. Worse, delayed projects lead to missed deadlines, unhappy clients, and lost business opportunities.

Herochu’s Pipe Storage Racking: Built for Efficiency, Safety, and Customization

Herochu’s Industry Pipe Storage and Racking Solutions solve these pain points by reimagining long material storage as a strategic part of your operation. We offer three specialized rack types—each designed to meet different needs—with features that prioritize durability, accessibility, and scalability.

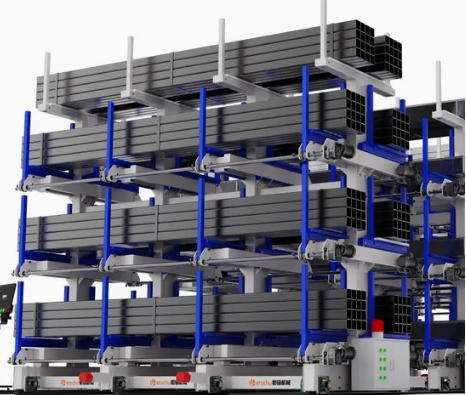

1. Cantilever Racks: The Gold Standard for Long, Heavy Pipes

Ideal for 10-40 foot pipes and heavy bars, Herochu’s cantilever racks feature sturdy vertical columns with extendable arms that eliminate front-facing posts—making loading and unloading a breeze. Whether you’re using a forklift or overhead crane, a single operator can access any pipe in seconds, no more shuffling stacks. Key benefits include:

- Heavy-Duty Capacity: Arms support 1,500-5,000 lbs per level, perfect for thick steel or stainless steel pipes.

- Adjustable Arms: Modify arm lengths and heights to fit different pipe diameters, from 2-inch tubing to 12-inch industrial pipes.

- Space-Saving Design: Reduces floor space usage by up to 70% compared to floor stacking, freeing up room for other operations.

A construction company in Texas recently switched to Herochu’s cantilever racks and reported a 40% reduction in material handling time, allowing them to take on two additional projects per month.

For pipes 2-10 feet long (like those used in plumbing or electrical work), Herochu’s vertical racks are a game-changer. These systems store materials upright in divided compartments, keeping pipes organized and off the floor. Benefits include:

- Floor Space Optimization: Reduces storage footprint by 80%—store 100+ pipes in the same space that once held 20.

- Damage Prevention: Dividers keep pipes separated, eliminating scratches and dents from rubbing or falling.

- Instant Access: Each compartment is labeled for easy identification, so employees can grab the right pipe in seconds.

A manufacturing plant in Ohio used vertical racks to organize their copper tubing inventory and cut material waste by 15%, saving $30,000 in the first year.

Herochu’s stacking racks are perfect for facilities that need to move pipes between locations or store materials temporarily. Made from high-grade steel, these racks are durable enough for outdoor use (with proper covering) and can be stacked 3-4 levels high when not in use. Key features include:

- Forklift Accessible: Open-base design allows easy lifting and moving, streamlining logistics.

- Weather Resistance: Optional powder-coating protects against rust and corrosion, ideal for construction sites or outdoor storage.

- Modular Design: Add or remove racks as needed, making them perfect for seasonal or project-based storage.

4. Fully Customizable to Your Workshop

No two facilities have the same needs, which is why every Herochu racking system is fully customizable. Our team works with you to design a solution that fits your space, materials, and workflow:

- Load Capacity: Choose from 1,500-10,000+ lb capacity per level, tailored to your pipe weights.

- Dimensions: Adjust arm lengths, column heights, and compartment sizes to fit your workshop’s layout.

- Accessories: Add dividers, labels, or weather covers to enhance organization and protection.

- Modular Growth: Start with a small system and add modules as your business expands—no need to replace your investment.

Why Herochu? Durability, Compliance, and Unmatched Support

Herochu’s Industry Pipe Storage and Racking Solutions aren’t just racks—they’re long-term investments in your business’s success. Here’s why we stand out from the competition:

- Certified Quality: All our racks meet CE, UE, and ISO 9001 standards, ensuring structural integrity and safety. We use 11-gauge steel for frames and 7-gauge steel for arms, so our systems can withstand years of heavy use.

- Tangible ROI: Starting at $3,099, our racks pay for themselves in months. Let’s break down the savings:

- Space Savings: Avoiding a $200,000 facility expansion by unlocking 70% of floor space.

- Labor Savings: Reducing material handling time by 40% saves $50,000+ per year in labor costs.

- Safety Savings: Avoiding one workplace injury saves $60,000+ in medical and legal fees.

- End-to-End Support: Our team of industrial storage experts provides free consultations, custom design, professional installation, and ongoing maintenance. We don’t just sell you a rack—we help you optimize your entire storage process.

Storage Best Practices: Get the Most Out of Your Herochu Racks

To maximize the lifespan of your pipes and racks, follow these expert tips (backed by our years of industry experience):

- Heavy Materials First: Store heavier pipes on lower levels to improve stability and reduce strain on upper arms.

- Outdoor Storage: If you need to store pipes outside, use our weather-resistant stacking racks and cover them with UV-protective tarps to prevent rust and sun damage.

- Clean and Dry: For long-term storage, keep your racking area clean and dry—this prevents corrosion, especially for stainless steel or aluminum pipes.

- Label Everything: Use our customizable labels to categorize pipes by material, diameter, and length—this eliminates “material hunts” and speeds up retrieval.

Ready to Transform Your Long Material Storage?

Herochu’s Industry Pipe Storage and Racking Solutions are the key to a safer, more efficient, and more profitable facility. Starting at $3,099, our customizable racks unlock space, reduce waste, and protect your team—all while delivering a 300%+ ROI in the first year.

Contact Herochu today to schedule a free consultation. Our experts will assess your facility, discuss your storage needs, and design a tailored solution that fits your budget. Don’t let disorganized pipes hold your business back—invest in Herochu and turn your long material storage from a liability into your most valuable asset.

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.