Plate Vacuum Lifters

Herochu re-engineers this fundamental process from the ground up. Our Plate Vacuum Lifters are not mere tools; they are sophisticated material handling partners that replace brute force with intelligent, air-powered precision. Starting at $2,689, this is a strategic investment that pays daily dividends in accelerated workflow, eliminated product damage, and a profoundly safer workshop environment. As a CE, UE, and ISO 9001 certified manufacturer, Herochu delivers a customizable solution that turns the most physically demanding task into your most streamlined operation.

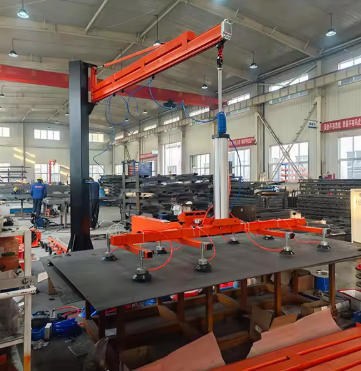

Herochu Plate Vacuum Lifters: Where Raw Metal Meets Effortless Control

In the heart of any metal fabrication shop, the most daunting challenge often isn’t the laser cutter or the press brake—it’s the raw material itself. The colossal, heavy, and notoriously difficult-to-handle sheets of steel, aluminum, and composites represent a constant operational bottleneck. Manual handling is slow, dangerous, and risks costly surface damage. Mechanical clamps can mar finishes and struggle with slick or delicate materials. This initial stage of production, the simple act of moving a plate, becomes a significant drain on time, safety, and profitability.

Herochu re-engineers this fundamental process from the ground up. Our Plate Vacuum Lifters are not mere tools; they are sophisticated material handling partners that replace brute force with intelligent, air-powered precision. Starting at $2,689, this is a strategic investment that pays daily dividends in accelerated workflow, eliminated product damage, and a profoundly safer workshop environment. As a CE, UE, and ISO 9001 certified manufacturer, Herochu delivers a customizable solution that turns the most physically demanding task into your most streamlined operation.

The Physics of Effort: How Vacuum Technology Transforms Your Workflow

The genius of the Herochu system lies in its elegant application of physics. By creating a powerful, consistent vacuum across an array of industrial-grade suction cups, the lifter forms a uniform, unbreakable bond with the material’s surface. This method of distributed force is a revelation compared to the point-load stress of clamps or the pinch-point dangers of slings. The result is a perfectly secure grip that leaves behind zero scratches, zero distortions, and zero oil stains. Your expensive stainless steel or pre-finished aluminum arrives at the machine bed in the same pristine condition it left storage.

This technology empowers a single operator to achieve what once required an entire team. Guiding the lifter is an intuitive process: position the adjustable suction cups, engage the vacuum, and command the effortless lifting, precise maneuvering, and gentle placement of sheets weighing up to 1,000 kg. The system allows for the load to be halted and held securely at any point in its trajectory, enabling millimeter-accurate alignment on a laser cutting table or a CNC router. This is not a minor improvement; it is a complete redefinition of material flow, transforming a logistical struggle into a ballet of controlled, efficient movement.

Precision-Engineered for the Demands of Modern Fabrication

Herochu lifters are built upon a foundation of robust engineering and user-centric design, incorporating features that directly address the real-world pains of shop floor operators.

-

The Core System: At the heart of every lifter is a meticulously selected, imported oil-free rotary vane vacuum pump. This critical component guarantees reliable, maintenance-free operation, ensuring there is no risk of oil contamination on your materials or your workshop floor. It’s the bedrock of the system’s unwavering performance.

-

Adaptable Mechanical Structure: Versatility is key to maximizing your return on investment. The suction frame and cups are fully adjustable in the X and Y directions, allowing you to quickly reconfigure a single lifter to securely handle a vast range of sheet sizes—from a compact 1250x1250mm piece to a sprawling 4000x1250mm plate. This flexibility eliminates the need for multiple, dedicated handling tools.

-

Ergonomic Design Intention: We designed these lifters with the operator’s well-being in mind. The outstanding lightweight and user-friendly structure, combined with an ergonomic operation height, ensures that control is always comfortable. This thoughtful design prevents fatigue, even during extended operation, enhancing both productivity and job satisfaction.

-

Universal Power & Flawless Rotation: With a wide AC power range (380V-440V, 50Hz/60Hz), the lifter integrates seamlessly into virtually any industrial power infrastructure. For ultimate versatility, many models can be equipped with an electric 90-degree flipping function. This allows an operator to smoothly rotate a sheet from a horizontal storage position to a vertical machining orientation with the simple push of a button, a game-changer for specific manufacturing processes.

The Herochu Safety Protocol: Engineering Confidence into Every Lift

Handling high-value, heavy loads requires absolute trust in your equipment. Herochu builds this confidence through an integrated, multi-sensory safety architecture.

The cornerstone of this system is the proactive, visual sound and light alarm. The moment the system detects a drop in vacuum pressure below the safe threshold, an immediate, unmistakable beacon and audible signal alert the operator. This provides crucial seconds to safely lower the load and investigate, preventing a potential accident before it can happen. This feature, designed in conformity with strict European safety requirements, acts as an ever-vigilant co-pilot.

Choosing Your Configuration: Agile Manipulator or Dedicated Lifter

Herochu offers distinct product lines to suit different operational tempos and capacity needs.

The Agile Pneumatic Manipulator: Ideal for high-cycle environments like feeding press brakes or organizing finished parts, this series is characterized by its light structure and easy disassembly. It offers rapid handling cycles and the ability to stop at any position, making continuous workflows both easy and safe, thanks to built-in air cut-off protection and anti-collision devices.

The Dedicated Plate Vacuum Lifter: This is the robust workhorse for primary material handling—loading laser cutters, transporting sheets from storage, and managing large-scale plates. It embodies all the core features of power, adjustability, and safety, making it the comprehensive solution for most fabrication needs.

Technical Specifications Overview:

| Model | Max. Plate Weight | Thickness Capacity | Suction Cup Array | Max. Sheet Size |

|---|---|---|---|---|

| HC-PR3015-500 | 500 kg | Up to 12mm | 8 x 200mm | 3000x1250mm |

| HC-PR3015-1000 | 1000 kg | Up to 20mm | 10 x 250mm | 3000x1250mm |

| HC-PR4020-500 | 500 kg | Up to 12mm | 8 x 200mm | 4000x1250mm |

All specifications serve as a starting point for customization. We specialize in designing case-by-case solutions to meet your exact sheet dimensions, weight requirements, and integration needs.

Stop allowing the weight of your materials to hold back your workshop’s potential. The Herochu Plate Vacuum Lifter is the pivotal upgrade that pays for itself by accelerating throughput, preserving material quality, and creating a safer, more sustainable work environment.

Contact a Herochu consultant today to discuss a customized solution. Let us demonstrate how transforming your material handling can become the most profitable decision you make this year.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Sheet Metal Storage Racks Solve Floor Space Problems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Double Vs. Single-Sided Cantilever Racking

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automated unloading system designed for laser steel plate cutting machines

Read moreRated 0 out of 5