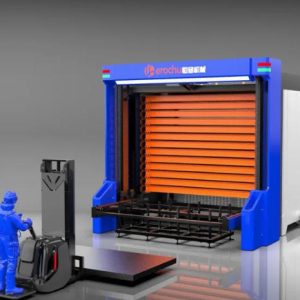

Roll Out Telescopic Cantilever Storage Rack for Efficient Long-Load Storage

That’s where Herochu’s Roll Out Telescopic Cantilever Storage Rack steps in. Engineered for efficiency, safety, and maximum space utilization, this system transforms how you store and access long loads—all while being customizable to your workshop, CE/UE/ISO 9001 certified, and starting at just $4,399. It’s not just storage; it’s a way to cut costs, speed up workflows, and protect your most valuable long materials.

Herochu Roll Out Telescopic Cantilever Storage Rack: The Game-Changer for Efficient Long-Load Storage

For warehouses, manufacturing plants, and fabrication shops drowning in disorganized long loads—aluminum profiles, steel pipes, bar stock, or lumber—traditional storage methods feel like a never-ending battle. Wide aisles waste space, manual lifting risks damage to materials and workers, and hunting for a specific 12-foot pipe buried behind stacks eats into production time. That’s where Herochu’s Roll Out Telescopic Cantilever Storage Rack steps in. Engineered for efficiency, safety, and maximum space utilization, this system transforms how you store and access long loads—all while being customizable to your workshop, CE/UE/ISO 9001 certified, and starting at just $4,399. It’s not just storage; it’s a way to cut costs, speed up workflows, and protect your most valuable long materials.

Why Traditional Long-Load Storage Is Holding You Back

If you’re still using fixed cantilever racks, pallet stacks, or floor piles for long loads, you’re probably familiar with these pain points:

- Wasted Space: Fixed racks require 8–10 feet of aisle space per row for forklifts—space that could be used for more storage or production.

- Slow Retrieval: Need a specific aluminum profile? You’ll spend 15+ minutes moving other materials out of the way, only to risk scratching the one you need.

- Damage Risks: Dragging pipes or profiles across each other (or the floor) causes dents, scratches, or bending—turning expensive materials into scrap.

- Safety Hazards: Manual lifting of 2–6 ton loads leads to back strains, while narrow gaps between stacks increase forklift collision risks.

These issues aren’t just annoying—they’re costly. A mid-size shop with inefficient long-load storage can lose $15,000+ annually to scrap, wasted labor, and missed deadlines. Herochu’s Roll Out Telescopic Cantilever Rack eliminates every one of these problems by putting “efficiency first” in every design choice.

What Makes Herochu’s Roll Out Telescopic Cantilever Rack Unique?

This isn’t just a “better rack”—it’s a reimagining of long-load storage. Herochu’s system combines telescopic extendable arms, heavy-duty construction, and smart automation to solve the biggest pain points of traditional storage. Here’s how it stands out:

1. Telescopic Roll-Out Arms: Full Access, Zero Hassle

The star feature? 100% extendable telescopic arms that pull fully outside the rack frame—no more reaching over or moving other materials to get what you need. Whether you’re storing 6-meter aluminum profiles or 12-meter steel pipes, each level is accessible in seconds:

- Manual or Automated Operation: Choose from crank-operated arms (perfect for smaller loads, 1.5–3 tons) or PLC frequency conversion control (for heavier loads up to 6 tons). The automated system lets you extend/retract arms with a push of a button—no more straining with cranks.

- No Wide Aisles Needed: Unlike fixed racks, you only need 3–4 feet of aisle space (just enough for a crane or forklift to access the extended arms). This cuts aisle space requirements by 50% or more—meaning you can fit 2x more storage in the same footprint.

- Individual Load Access: Every long load has its own dedicated arm. No more stacking pipes on top of each other—grab the exact one you need without touching the rest. This eliminates scratches, dents, and bending, keeping your materials in “as-new” condition.

Imagine needing a 9-meter steel bar for a client order. With Herochu’s rack, you press a button to extend the arm, lower your crane, and lift the bar directly—no moving other pipes, no wasted time, no damage. That’s efficiency redefined.

2. Heavy-Duty Capacity: Handles Your Heaviest Long Loads

Long materials like thick aluminum profiles or steel pipes aren’t light—and your rack needs to keep up. Herochu’s system is built for industrial strength, with options to match your load requirements:

|

Model

|

Storage Sheet Size

|

Load Per Layer

|

Number of Layers

|

Total Loading Per Rack

|

Single/Double Arms

|

|

HC-G6053S

|

6000mm (6m)

|

2tons

|

3+1

|

8tons

|

|

|

HC-G6053D

|

6000mm (6m)

|

3tons

|

4+1

|

25tons

|

|

|

HC-G9055S

|

9000mm (9m)

|

5tons

|

3+1

|

35tons

|

Double

|

|

HC-G9055D

|

12000mm (12m)

|

6tons

|

3+1

|

42tons

|

Double

|

Need something bigger? Our customizable option lets you adjust every detail:

- Storage Size: Go beyond 12m—we’ll build racks for 15m, 18m, or even longer materials.

- Load Capacity: Upgrade to 8tons per layer or 50+ tons total per rack for ultra-heavy loads.

Every component—from the arms to the frame—is made from high-strength Q235 steel (the same material used in construction beams) and welded with precision. This isn’t a rack that will bend or wear out after a few months—it’s built to last decades, even in busy industrial environments.

3. PLC Frequency Conversion Control: Smart, Safe Automation

For shops handling high volumes of long loads, automation is a game-changer. Herochu’s PLC frequency conversion control system turns manual labor into a one-person job:

- Smooth, Controlled Movement: The system adjusts speed automatically based on load weight—slower for heavy loads (6tons) to prevent shifting, faster for lighter ones (2tons) to save time. No more jerky movements that risk damaging materials.

- Safety Locks: Built-in sensors prevent multiple arms from extending at once (a common cause of rack instability). If an arm is overloaded, the system shuts down automatically—protecting workers and materials.

- Easy Integration: Sync the rack with your warehouse management software (WMS) to track inventory. Know exactly where each load is, how many you have left, and when to reorder—no more manual counting.

Even small shops benefit: the automated system lets one operator handle loading/unloading that used to require two people. That’s a 50% reduction in labor costs for long-load storage.

4. Space-Saving Design: Maximize Every Inch of Your Workshop

Floor space is the most valuable asset in any warehouse—and Herochu’s rack lets you use it wisely. Here’s how:

- Narrow Aisles: As mentioned, only 3–4 feet of aisle space is needed (vs. 8–10 feet for fixed racks). For a 100-foot-long warehouse, that’s 50+ extra square feet of storage space.

- Vertical Scalability: Adjust the distance between layers (600mm for standard loads, 800mm for taller ones) to fit more layers in your ceiling height. A 10-foot ceiling can fit 4+1 layers—double the storage of a fixed rack.

- Double-Arm Options: Models like the HC-G6053D or HC-G9055S have double arms, letting you store two loads per layer (e.g., two 6m aluminum profiles side by side). This doubles storage density without increasing the rack’s footprint.

For small workshops or urban warehouses where space is at a premium, this design is a lifesaver. You can store 3x more long loads in the same space as traditional racks—no need to expand your facility.

5. Durable Finish & Safety Features: Protect Your Investment

Warehouses are tough environments—dust, moisture, and accidental impacts are part of the job. Herochu’s rack is built to withstand it all:

- Powder-Coated Finish: Arms and frames are coated with a baked-on powder epoxy finish that’s scratch-resistant (no chipping from forklift bumps) and corrosion-resistant (protects against moisture or chemical spills). Choose from Orange/Blue (standard) or customize the color to match your workshop’s branding.

- Anchoring Requirements: We recommend anchoring the rack to the floor to ensure stability—even under maximum load. For extra protection, add our optional impact guards (sold separately) to shield the frame from accidental forklift hits.

- Global Safety Certifications: Every rack meets CE, UE, and ISO 9001 standards. Whether you’re operating in the US, Europe, or Asia, you can trust that your storage complies with the strictest safety regulations—keeping your workers and materials safe.

Who Benefits Most from Herochu’s Roll Out Telescopic Cantilever Rack?

This system isn’t just for large factories—it’s tailored to any operation that deals with long loads:

- Aluminum Fabricators: Store profiles of all lengths (6m, 9m, 12m) without scratching, with easy access for cutting and assembly.

- Construction Companies: Keep steel pipes, rebar, and lumber organized on job sites—no more tripping over floor stacks or wasting time searching for materials.

- Mechanical Contractors: Store HVAC ducts, copper pipes, and electrical conduit efficiently, with quick retrieval for on-site installations.

- Furniture Manufacturers: Store long wooden beams or metal rails without bending or warping, using the soft-contact arm padding (optional) to protect delicate surfaces.

- Automotive Suppliers: Store long metal rods or aluminum extrusions used in car frames—with PLC control to handle high-volume, time-sensitive orders.

No matter your industry, if long loads are slowing you down or costing you money, Herochu’s rack will transform your workflow.

The Financial Impact: Inefficient Storage vs. Herochu’s Rack

Let’s break down the numbers for a mid-size aluminum fabricator that uses traditional fixed racks:

- Space Waste: 500 square feet of unused space (due to wide aisles) =

5,000/yearinloststoragepotential(basedon

10/sq ft/year warehouse costs).

- Scrap Costs: 10 scratched aluminum profiles/month (

300each)=

36,000/year in wasted materials.

- Labor Costs: 2 workers spending 10 hours/week on material retrieval =

52,000/yearinwastedlabor(basedon

25/hr per worker).

- Accident Costs: 1 forklift collision/year (damaging racks and materials) = $10,000/year in repairs and downtime.

Total Annual Cost of Inefficient Storage: $103,000

With Herochu’s rack:

- Space Savings: Recover 500 square feet = $5,000/year saved.

- Scrap Reduction: 95% fewer scratched profiles = $34,200/year saved.

- Labor Savings: 1 worker handling retrieval = $26,000/year saved.

- Accident Prevention: 0 collisions (due to safety locks and narrow aisles) = $10,000/year saved.

Total Annual Savings: $75,200

With a starting price of $4,399, the rack pays for itself in just 7 weeks. After that, every dollar saved goes straight to your bottom line. This isn’t an expense—it’s the most profitable investment you’ll make in your workshop.

Why Choose Herochu? Because Your Long Loads Deserve the Best

There are plenty of rack manufacturers—but none focus exclusively on long-load efficiency like Herochu. Here’s what sets us apart:

- Customization Without Compromise: We don’t just offer “standard sizes”—we’ll build a rack that fits your exact needs, from 6m to 18m lengths, 2tons to 8tons per layer.

- Fast Delivery: Pre-designed models (HC-G6053S, HC-G6053D, etc.) ship in 2–3 weeks—no waiting months for custom fabrication.

- Lifetime Support: From installation (our team sets it up correctly, so you don’t have to) to annual maintenance (we check for wear and tear), we’re with you every step of the way.

- Proven Results: Our clients report a 60% increase in storage density, 70% faster material retrieval, and 95% fewer scratched materials—all within the first month of use.

This isn’t just a rack. It’s a partnership to make your workshop more efficient, safer, and more profitable.

Invest in Efficiency: Start at $4,399

For a limited time, Herochu’s Roll Out Telescopic Cantilever Storage Rack starts at just $4,399—less than the cost of one month of scrap for most shops. And because we’re confident in our product, we offer a 60-day satisfaction guarantee: if you’re not seeing faster retrieval, more storage space, and fewer scratches, we’ll adjust the rack or give you a full refund.

Don’t let inefficient storage hold you back. Herochu’s rack lets you store more long loads, retrieve them faster, and protect them from damage—all while saving space and labor.

Ready to transform your long-load storage? Contact Herochu today for a free, no-obligation consultation. We’ll assess your workshop, recommend the perfect model (standard or custom), and show you exactly how much you could save. Your floor space, your workers, and your bottom line will thank you.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Telescopic Cantilever Racking Systems For Aluminium Profiles

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Telescopic Cantilever Storage Rack for Efficient Long-Load Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racks & Lumber Racks for Sale

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & used heavy duty cantilever racks for sale

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Heavy Duty Plate Storage Warehouse

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automated Plate Warehouse with High Load Capacity

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5