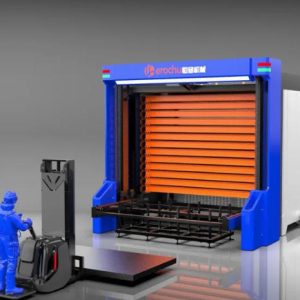

Steel Plate Lifting Handling Manipulator

The arm parks above your rack of blanks. Pull the trigger on the pistol grip: eight venturi cups drop, hug the plate, and lift it clear while the mast glides forward on sealed bearings. A gentle rotation drops the sheet onto the cutting table pins; cups release, arm retracts, cycle done. The whole choreography needs less air than a single impact wrench and draws only 0.4 kWh per shift—cheaper than the coffee the operator would sip while waiting for the forklift.

Herochu Steel-Plate Lifting Handling Manipulator

Start at $2 999 · CE / ISO 9001 · Built for your table size · Ships in 10 days

Start at $2 999 · CE / ISO 9001 · Built for your table size · Ships in 10 days

A laser only earns when the beam is on. Between those sparks lies the real job: getting a 4 m, 300 kg sheet from the stillage to the shuttle without kinking an edge, scraping the paint, or calling two extra people who are already busy wrestling a different nest. The Herochu cantilever manipulator turns that 15-minute wrestling match into a 45-second solo dance—pneumatic suction, powered articulation, one-hand control, zero strain.

From flat-pack to first cut in under a minute

The arm parks above your rack of blanks. Pull the trigger on the pistol grip: eight venturi cups drop, hug the plate, and lift it clear while the mast glides forward on sealed bearings. A gentle rotation drops the sheet onto the cutting table pins; cups release, arm retracts, cycle done. The whole choreography needs less air than a single impact wrench and draws only 0.4 kWh per shift—cheaper than the coffee the operator would sip while waiting for the forklift.

The arm parks above your rack of blanks. Pull the trigger on the pistol grip: eight venturi cups drop, hug the plate, and lift it clear while the mast glides forward on sealed bearings. A gentle rotation drops the sheet onto the cutting table pins; cups release, arm retracts, cycle done. The whole choreography needs less air than a single impact wrench and draws only 0.4 kWh per shift—cheaper than the coffee the operator would sip while waiting for the forklift.

Built like a machine tool, not a gadget

The backbone is 180 × 180 × 8 mm square steel, laser-cut and fish-plate welded to take 1 000 kg at full reach without whispering. Pivot pins run in graphite-bronze bushings; no plastic sleeves to crush or replace. The suction bar floats on a parallelogram linkage so eight cups share the load even when the sheet bows or carries mill-scale ridges. A 60-micron filter/water separator keeps airlines dry; cup life stretches past 18 months in coastal humidity. Every joint carries a grease nipple—one pump every 500 cycles, five minutes, done.

The backbone is 180 × 180 × 8 mm square steel, laser-cut and fish-plate welded to take 1 000 kg at full reach without whispering. Pivot pins run in graphite-bronze bushings; no plastic sleeves to crush or replace. The suction bar floats on a parallelogram linkage so eight cups share the load even when the sheet bows or carries mill-scale ridges. A 60-micron filter/water separator keeps airlines dry; cup life stretches past 18 months in coastal humidity. Every joint carries a grease nipple—one pump every 500 cycles, five minutes, done.

Three bodies, one brain

Choose the throat that matches your bed: 1 500 mm for 3 m shuttle tables, 2 000 mm for 4 m fibre monsters. Lift height starts at 300 mm and climbs to 1 200 mm so you can feed a 200 mm table or clear a 900 mm sorting conveyor without swapping tools. Rated loads step 300 kg, 500 kg, 1 000 kg—same frame, bigger cylinder, different relief valve. One PLC box lives under the mast; cable sets are numbered and pluggable so a maintenance tech can swap a sensor in the time it takes to change a nozzle.

Choose the throat that matches your bed: 1 500 mm for 3 m shuttle tables, 2 000 mm for 4 m fibre monsters. Lift height starts at 300 mm and climbs to 1 200 mm so you can feed a 200 mm table or clear a 900 mm sorting conveyor without swapping tools. Rated loads step 300 kg, 500 kg, 1 000 kg—same frame, bigger cylinder, different relief valve. One PLC box lives under the mast; cable sets are numbered and pluggable so a maintenance tech can swap a sensor in the time it takes to change a nozzle.

Pneumatic muscles, electric nerves

We use air for brute force—clean, intrinsically safe, always available—and 24 V DC for brains. A magnetic encoder tracks boom angle; the screen shows live load, cup vacuum and cycle count. If vacuum drops below −55 kPa during a lift the valve block locks and the arm gently sets the sheet back down—no drama, no dropped parts, no midnight call to the insurance broker. The pendant is IP 65; weld spatter just bounces off.

We use air for brute force—clean, intrinsically safe, always available—and 24 V DC for brains. A magnetic encoder tracks boom angle; the screen shows live load, cup vacuum and cycle count. If vacuum drops below −55 kPa during a lift the valve block locks and the arm gently sets the sheet back down—no drama, no dropped parts, no midnight call to the insurance broker. The pendant is IP 65; weld spatter just bounces off.

Space is money—keep both

The footprint is a single square metre. When the shift ends the boom parks vertically, leaving aisles free for sweepers or a pallet truck. Compare that to the three-metre corridor a forklift needs for turning and you realise the manipulator often pays for itself in reclaimed floor before the first year is out. Ceiling height? If you can stand the sheet up, the arm will reach it—up to 4 m under hook without a mezzanine.

The footprint is a single square metre. When the shift ends the boom parks vertically, leaving aisles free for sweepers or a pallet truck. Compare that to the three-metre corridor a forklift needs for turning and you realise the manipulator often pays for itself in reclaimed floor before the first year is out. Ceiling height? If you can stand the sheet up, the arm will reach it—up to 4 m under hook without a mezzanine.

One operator, eight hours, zero backache

Manual feeding teams usually run two people: one to steady, one to drive. The manipulator cuts that to a single setter who never lifts more than a game-controller. In field tests customers shaved 40 labour minutes off every nest change. Run fifteen nests a day and you have gifted yourself ten extra machine hours daily—enough capacity to accept that rush job without touching overtime.

Manual feeding teams usually run two people: one to steady, one to drive. The manipulator cuts that to a single setter who never lifts more than a game-controller. In field tests customers shaved 40 labour minutes off every nest change. Run fifteen nests a day and you have gifted yourself ten extra machine hours daily—enough capacity to accept that rush job without touching overtime.

Metals, woods, plastics—no prejudice

Cup compound is shore-60 nitrile: oil-resistant, mark-free on polished stainless, yet happy on rough-sawn plywood or acrylic with protective film. Swap to blue silicone for high-temp pickled plate, or foam rings for perforated sheets—thirty-second change, no tools. We once fed 12 mm copper busbar straight into a punching centre; another user loads MDF boards into a CNC router. Same arm, different day.

Cup compound is shore-60 nitrile: oil-resistant, mark-free on polished stainless, yet happy on rough-sawn plywood or acrylic with protective film. Swap to blue silicone for high-temp pickled plate, or foam rings for perforated sheets—thirty-second change, no tools. We once fed 12 mm copper busbar straight into a punching centre; another user loads MDF boards into a CNC router. Same arm, different day.

Installation that does not hijack the weekend

The manipulator ships bolted to a steel baseplate. Drop four M16 anchors, connect ½” air line and 230 V single phase, run the self-calibration routine—thirty minutes and the arm is ready for production. No pit, no civil work, no factory air upgrade. If you move premises, unbolt it, fork it onto a truck, and reinstall it before the coffee gets cold.

The manipulator ships bolted to a steel baseplate. Drop four M16 anchors, connect ½” air line and 230 V single phase, run the self-calibration routine—thirty minutes and the arm is ready for production. No pit, no civil work, no factory air upgrade. If you move premises, unbolt it, fork it onto a truck, and reinstall it before the coffee gets cold.

Price that respects cash-flow

Entry model 300 kg, 1 500 mm reach, eight-cup array: $2 999 ex-works. That is less than the cost of one hernia claim or three weeks of idle laser rent. Step to 1 000 kg heavy-duty and you are still below the price of a used forklift that will need fuel, tyres, and a licence. Spare cup sets start at $12; a complete seal kit is $89—maintenance budgets stay asleep.

Entry model 300 kg, 1 500 mm reach, eight-cup array: $2 999 ex-works. That is less than the cost of one hernia claim or three weeks of idle laser rent. Step to 1 000 kg heavy-duty and you are still below the price of a used forklift that will need fuel, tyres, and a licence. Spare cup sets start at $12; a complete seal kit is $89—maintenance budgets stay asleep.

Ten-year frame, two-year everything else

We weld, machine, and paint in one facility; every serial is logged to steel heat number and test report. The frame carries a ten-year warranty; pneumatic and electric components two years. A QR plate on the mast links to a video library: how to set vacuum, how to bleed the circuit, how to swap a cup while the kettle boils. If you prefer human eyes we video-diagnose in under an hour and ship parts within 24 h from regional hubs.

We weld, machine, and paint in one facility; every serial is logged to steel heat number and test report. The frame carries a ten-year warranty; pneumatic and electric components two years. A QR plate on the mast links to a video library: how to set vacuum, how to bleed the circuit, how to swap a cup while the kettle boils. If you prefer human eyes we video-diagnose in under an hour and ship parts within 24 h from regional hubs.

Stop renting strain

Every plate you man-handle is a coin someone else picks up: lost minutes, bent corners, aching backs. Bolt a Herochu manipulator to the floor and those coins stay in your pocket. Feed faster, cut sooner, ship earlier—turn the laser into the pacemaker of the shop and let the arm do the heavy breathing. Your operator will walk taller at the end of the shift, and the beam will still be burning while the other guys are hunting for their next sheet.

Every plate you man-handle is a coin someone else picks up: lost minutes, bent corners, aching backs. Bolt a Herochu manipulator to the floor and those coins stay in your pocket. Feed faster, cut sooner, ship earlier—turn the laser into the pacemaker of the shop and let the arm do the heavy breathing. Your operator will walk taller at the end of the shift, and the beam will still be burning while the other guys are hunting for their next sheet.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Telescopic Cantilever Racking Systems For Aluminium Profiles

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Telescopic Cantilever Storage Rack for Efficient Long-Load Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racks & Lumber Racks for Sale

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & used heavy duty cantilever racks for sale

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Heavy Duty Plate Storage Warehouse

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automated Plate Warehouse with High Load Capacity

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5