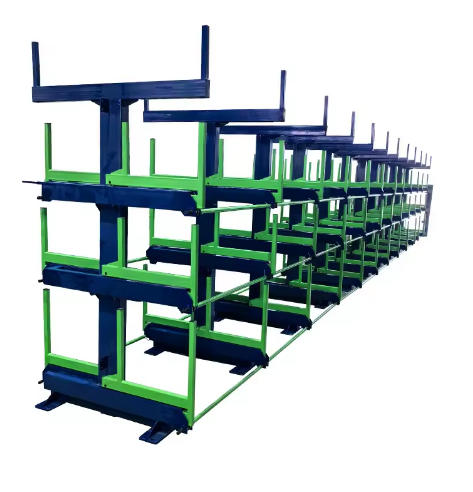

Storage solution for long timber packs

Herochu Long Timber Pack Rack – The Storage Solution for Timber That Grows With Your Yard

Timber packs don’t get shorter once they leave the sawmill. They lean, they bow, they sprawl across forklift lanes until your yard feels like an obstacle course. Herochu’s Roll-Out Cantilever System, built specifically as a storage solution for long timber packs, turns that clutter into a vertical library where every plank, beam, or molding is reachable in under a minute. Starting at $3,099, fully CE/UE/ISO 9001 certified, and customizable down to the last millimetre, this rack is the missing wall between a chaotic timber yard and a cash-flow-friendly workflow.

Herochu Long Timber Pack Rack – The Storage Solution for Timber That Grows With Your Yard

Timber packs don’t get shorter once they leave the sawmill. They lean, they bow, they sprawl across forklift lanes until your yard feels like an obstacle course. Herochu’s Roll-Out Cantilever System, built specifically as a storage solution for long timber packs, turns that clutter into a vertical library where every plank, beam, or molding is reachable in under a minute. Starting at $3,099, fully CE/UE/ISO 9001 certified, and customizable down to the last millimetre, this rack is the missing wall between a chaotic timber yard and a cash-flow-friendly workflow.

Vertical Air Is Cheaper Than Horizontal Concrete

A single HC-G9055D tower stands only 1,200 mm wide yet swallows 42 tons of timber across four motorized levels. Instead of pouring new slab, you build upward, freeing aisles wide enough for a Combilift to snake through without bumping a single pack. One customer in Oregon reclaimed 2,400 ft²—enough floor to install a second resaw and add a second shift without extending the building lease.

Motorized Roll-Out Arms—No Winch, No Wrestle

Each cantilever arm rides on sealed bearings and a PLC frequency-conversion drive. Press the remote and the arm glides out at 0.3 m/s, smooth enough for wrapped cedar yet fast enough to keep the optimizer line humming. The inverter senses load weight and auto-adjusts torque, so a 200 kg pack of primed finger-joint moves as effortlessly as a bundle of balsa. Forget the old “hook-and-hope” method; one operator can stage a 6 m pack while the forklift stays on the next job.

Capacities That Match Real Timber, Not Theory

Choose from five pre-engineered frames or mix-and-match:

-

HC-G6053S – 8 t total, 2 t per level, perfect for short off-cuts and molding stock.

-

HC-G6053D – 25 t total, 3 t per arm, the go-to for 4×4 pressure-treated bundles.

-

HC-G9055S – 35 t total, 5 t per level, built for 6 m engineered beams.

-

HC-G9055D – 42 t total, 6 t per arm, ready for 9 m glulam or LVL.

-

Custom – any length, any load, any colour; we have punched arms for 12 m packs weighing 8 t each and painted them forest-green to keep the council happy.

Arms telescope in 50 mm increments, so a mixed load of 38×235 mm rafters and 89×38 mm battens lives on the same tower without spacers or plywood shims.

Timber Stays Straight, Dry, and Saleable

Storing long timber on uneven ground invites twist and cup. Herochu arms are laser-leveled to ±1 mm across the entire bay, eliminating sag. Optional UV-resistant roof panels clip to the top beam, turning outdoor yards into covered storage for less than the cost of a timber tarp that flaps in the wind. Ventilated end-stops keep packs 100 mm off the ground, letting air circulate so MC levels stay stable and your kiln operator doesn’t fight hidden wet pockets.

Safety Pins That Speak louder Than Paperwork

Bright-orange shear pins lock arms to the mast at the chosen height and act as a visual load limit. If you can see orange, the arm is seated; if the pin shears, the load settles onto the backup dog, buying time for a controlled offload. No bent arms, no surprise drops, no near-miss reports. One Quebec mill cut lost-time injuries to zero the first year after installing eight HC-G9055D towers—its insurer noticed and dropped the premium by 11 %.

Paint That Survives Pressure-Washing

Timber yards are dusty, then suddenly muddy, then pressure-washed at 3,000 psi. Herochu racks go through a five-stage blast line, zinc-rich primer, and 80 µm polyester powder coat rated for 1,000 hours salt-spray. Blue mast, orange arms come standard; choose custom RAL colours to match corporate livery or safety zoning without extra lead time.

Bolt-Together, Not Weld-Together

Knocked-down kits ship in steel returnable frames—no single-use timber crating to dispose of. Two workers, two wrenches, and 45 minutes assemble a 6 m tower. Uprights arrive pre-punched; arms slot in like giant drawer slides. Need to relocate the rack when the yard re-flows? Unbolt, move, re-level. No cutting torch, no hot-work permit, no downtime.

PLC Controls That Talk to Your WMS

The standard HMI panel logs every arm movement and exports CSV via Ethernet. Tie it into your existing warehouse management system and you’ll know which pack entered the yard at 09:14 and which left at 14:37—traceability for FSC-certified or heat-treated stock without manual spreadsheets. Optional RFID arm pads read tagged bundles automatically, updating inventory while the forklift driver grabs a coffee.

ROI in Two Seasons, Not Two Decades

A British Columbia truss plant swapped floor stacking for six HC-G9055D racks. Timber retrieval time dropped from 18 minutes to 3 minutes per pack, freeing 26 forklift hours per week. At CAD $80/hour burdened rate, the system paid for itself in 7.5 months—before counting the 2 % drop in warp-related waste. They reinvested the savings in a second shift and still had cash left for a barbecue that didn’t come out of the maintenance budget.

From PVC Pipe to Glulam—Same Skeleton, Different Skin

Although PVC and timber diameters differ, the engineering math is identical: long, heavy, awkward. Herochu’s cantilever core originated in plastic pipe yards, so the arms already tolerate UV, chemical splash, and -30 °C brittleness. Swap the timber stop for a pipe saddle and the same tower stores 250 mm sewer line Monday and 300×45 mm rafters Friday—no new rack, no capital committee meeting.

Global Certifications, Local Support

Every weld is ultrasonic-tested and logged against the CE declaration; ISO 9001 paperwork rides with the shipment. Stateside or EU site? A Herochu field engineer will fly in for start-up calibration, operator training, and the first preventive inspection—cost baked into the quote, not hidden in fine print. Spare pins, motors, and HMI screens sit in regional warehouses, so a replacement lands overnight, not on the slow boat.

Ready to Straighten Your Yard?

Measure the longest pack you stock, the weight your forklift is rated for, and the height your loader can reach. Type those three numbers into the Build-My-Rack widget and you’ll have a stamped drawing, freight cost, and payback curve before your coffee cools. Or call 1-800-HEROCHU and talk to a former timber-yard foreman who still carries a caliper on his belt. Either way, stop planning around piles and start planning around profit—one motorized arm at a time.

Herochu Long Timber Pack Rack

Store it straight. Retrieve it fast. Sell it sooner.

Store it straight. Retrieve it fast. Sell it sooner.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industrial Roll-out Telescopic Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Storage solution for long timber packs

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty Storage racks for steel profiles

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Storage steel sheets racks measuring 1500×3000 or 3500mm for 3t sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Optimizing Warehouse Efficiency with Pipe Racking systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industry Pipe Storage and Racking Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5