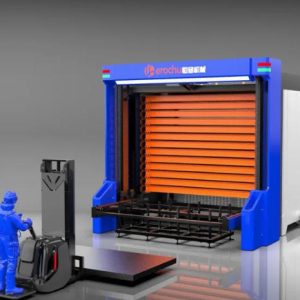

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

But the benefits don’t stop there. Our racks maximize vertical space—one of the most underutilized assets in any workshop. Compared to floor storage or basic horizontal racks, Herochu’s Heavy Duty Steel Racks increase storage density by up to 400%. Imagine storing 4x more steel plates in the same footprint: that’s space freed up for new machinery, additional workstations, or streamlined inventory staging. For facilities experiencing explosive growth, this isn’t just a convenience—it’s a way to scale without relocating or expanding your space.

Herochu Heavy Duty Steel Racks for Steel Plate: Transform Your Workshop Storage, Starting at $4,399

In the fast-paced world of manufacturing, where every square foot of floor space and every minute of production time counts, inefficient steel plate storage can become a costly bottleneck. Laser and punching machines are faster than ever—yet outdated storage systems leave raw materials scattered, inaccessible, or at risk of damage, slowing down workflows and eating into profits. That’s where Herochu’s Heavy Duty Steel Racks for Steel Plate come in: engineered to solve your storage challenges with durability, customization, and efficiency at their core. CE, UE, and ISO 9001 certified, these racks aren’t just storage—they’re a strategic investment in your workshop’s growth.

Why Herochu Steel Plate Storage Racks Outperform Traditional Solutions

For years, manufacturers have relied on makeshift storage: stacking steel plates on the floor (cumbersome, risky, and space-hungry), using generic racks (ill-fitted for standard sheet sizes), or manual horizontal shelves (requiring backbreaking labor to move materials). Herochu’s design flips the script, focusing on three critical pain points: space savings, safety, and ease of use.

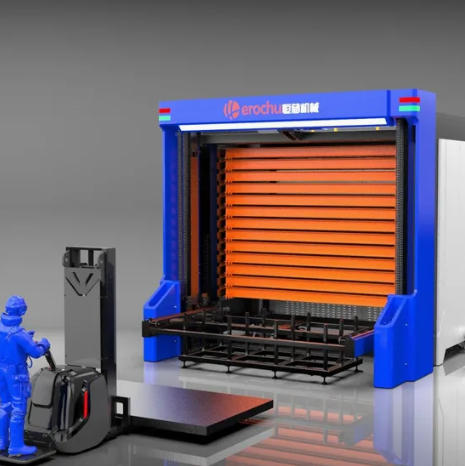

Take our signature Drawer-style Steel Plate Storage Shelves—a game-changer for workshops of all sizes. Unlike traditional vertical racks that force workers to reach or lift awkwardly, these roll-out drawers glide on heavy-duty steel bearings, putting every steel plate within arm’s reach. No more strained muscles from manual handling, no more wasted time hunting for the right gauge, and no more damaged edges from mishandling. It’s ergonomic design that translates directly to faster, safer operations.

But the benefits don’t stop there. Our racks maximize vertical space—one of the most underutilized assets in any workshop. Compared to floor storage or basic horizontal racks, Herochu’s Heavy Duty Steel Racks increase storage density by up to 400%. Imagine storing 4x more steel plates in the same footprint: that’s space freed up for new machinery, additional workstations, or streamlined inventory staging. For facilities experiencing explosive growth, this isn’t just a convenience—it’s a way to scale without relocating or expanding your space.

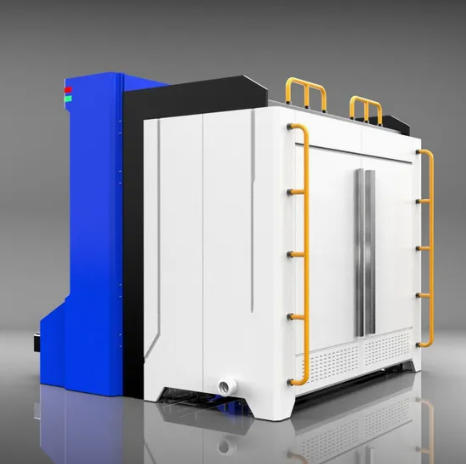

Built for Heavy-Duty Use: Durability That Lasts

Steel plates are heavy, bulky, and expensive—your storage system needs to match their demands. Herochu’s Heavy Duty Steel Racks are constructed with a sturdy welded steel framework that’s built to withstand the rigors of industrial use. No flimsy bolts, no weak joints—just robust, reliable support that protects your materials and your investment.

Each shelf is engineered to handle impressive loads, with standard capacities ranging from 3 tons to 6 tons per layer (that’s 6,000 to 12,000 pounds). For workshops with even heavier needs, we offer custom configurations that can support up to 10 tons per shelf—perfect for thick steel plates or high-volume inventory. And because we understand that steel plates come in all sizes, our racks accommodate standard dimensions (3000x1500mm, 4000x1500mm, 4000x2000mm, 6000x2000mm) and can be fully customized to fit your unique plate sizes.

Let’s break down our standard models to see how they fit into your workflow:

|

Model

|

Plate Size (mm)

|

Load per Layer

|

Number of Layers

|

External Dimensions (LxHxW mm)

|

Door Open Width (mm)

|

|

HC-B3015-63

|

3000×1500

|

3t

|

5+1

|

3505x2280x2000

|

3515

|

|

HC-B4015-63

|

4000×1500

|

3t

|

5+1

|

4505x2280x2000

|

4015

|

|

HC-B4020-65

|

4000×2000

|

5t

|

5+1

|

4505x2280x2500

|

N/A

|

|

HC-B6020-66

|

6000×2000

|

6t

|

5+1

|

6505x2280x2500

|

N/A

|

Every model features an integrated pull-out drawer system for smooth access, a bottom-layer ground clearance of 355mm (to protect plates from moisture or debris), and a top-floor height of up to 2250mm (maximizing vertical space). The partition layers offer a maximum height of 220mm—ideal for storing different gauges or plate types without mixing inventory.

Customization: Tailored to Your Workshop’s Exact Needs

No two workshops are the same—so why settle for a one-size-fits-all storage system? Herochu’s Heavy Duty Steel Racks are fully customizable, designed to adapt to your space, your materials, and your workflow. Whether you need a specific plate size, additional layers, higher load capacities, or double-sided loading (for easy access from multiple workstations), our team will work with you to create a solution that fits like a glove.

For example, if your workshop uses extra-large 8000x2500mm steel plates, we can modify our HC-B series to accommodate that size. If you need 8 layers instead of the standard 5+1, we’ll adjust the height and reinforcement to maintain safety and durability. Even small details—like adding depth pads (standard 60mm, customizable to your needs) or adjusting drawer movement for compatibility with your lift systems—are handled with precision.

This level of customization isn’t just about convenience—it’s about creating a lean manufacturing environment. When your storage system is tailored to your operations, you eliminate wasted time, reduce material waste, and ensure that every steel plate is exactly where you need it, when you need it. It’s the difference between a disorganized staging area and a streamlined workflow that keeps your crews productive and your projects on track.

Seamless Integration with Your Existing Equipment

Herochu’s Heavy Duty Steel Racks aren’t just standalone storage—they’re designed to work with the tools you already use. Whether you rely on vacuum lifters, hoists, magnetic lifters, or forklifts, our roll-out drawers make loading and unloading steel plates faster and safer than ever.

Unlike cantilever racks (which struggle with standard sheet stock sizes) or generic storage racks (which often require awkward maneuvering), our roll-out design extends outward, putting steel plates in the optimal position for your lift equipment. No more struggling to align a forklift with a narrow shelf or risking damage to plates with a vacuum lifter that can’t reach—Herochu’s racks are engineered for seamless integration.

And for workshops that still use manual handling for smaller jobs, our vertical storage options offer easy access without sacrificing space. Unlike horizontal racks (which top out at 2,000 pounds per shelf), our vertical designs handle heavy loads while keeping plates visible and accessible—perfect for quick inventory checks or last-minute material retrievals.

The Returnable Advantage: Reduce Waste, Lower Costs

In addition to our Heavy Duty Steel Racks, Herochu offers Returnable Sheet Metal Storage Systems—a sustainable solution that cuts down on disposable packaging waste and shipping costs. These modular systems allow you to stack and shuttle cartridges to and from your suppliers, eliminating the need for cardboard boxes, wooden crates, or plastic wrap.

For manufacturers that order steel plates in bulk, this is a game-changer. Not only do you reduce your environmental footprint (a win for both your brand and the planet), but you also save money on packaging materials and shipping fees. And because the cartridges are designed to fit our steel racks, you can seamlessly integrate them into your existing storage workflow—no extra steps, no extra space needed.

Why Choose Herochu? More Than Just Racks—A Partner in Growth

When you invest in Herochu’s Heavy Duty Steel Racks, you’re not just buying storage—you’re partnering with a company that understands the unique challenges of manufacturing. Our CE, UE, and ISO 9001 certifications aren’t just labels—they’re a promise of quality, safety, and reliability. We’ve helped countless workshops streamline their operations, reduce waste, and scale their businesses—all by reimagining how steel plates are stored and handled.

Installation is a breeze, too. Our team works with you to schedule setup at a time that doesn’t disrupt your production, and we provide training to ensure your crew knows how to use the racks safely and efficiently. And with ongoing support, you can count on us to address any questions or concerns long after the racks are installed.

Starting at $4,399, our Heavy Duty Steel Racks are an investment that pays for itself. Think about it: less time wasted hunting for materials, fewer damaged plates, more floor space for revenue-generating equipment, and lower shipping/packaging costs. It’s not just storage—it’s a way to boost your bottom line.

Ready to Transform Your Workshop?

If your current steel plate storage is holding you back, it’s time to make a change. Herochu’s Heavy Duty Steel Racks are customizable, durable, and designed to grow with your business. Whether you need a standard model (like the HC-B3015-63 for 3000x1500mm plates) or a fully custom solution, we’ll help you create a storage system that fits your needs—and your budget.

Don’t let inefficient storage slow down your growth. Contact Herochu today to learn more about our Heavy Duty Steel Racks for Steel Plate and how we can help you build a leaner, more efficient workshop.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty cantilever sheet metal rack

Read moreRated 0 out of 5