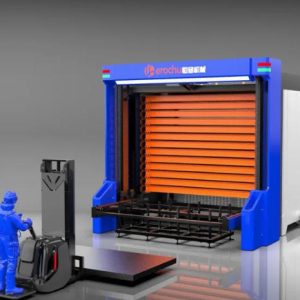

Herochu Custom Roll-Out Rack Systems for Elevator Parts

From USD 4,399 | CE • UE • ISO 9001 | Ships in 20 days | Made-to-Measure for 6 m Mirror-Finish Panels

An elevator car is judged the moment the doors open—fingerprints on the #4 finish, a hair-line scratch across the grain, and the entire cabin feels cheap. Yet the same fabricator who polishes every edge to a razor shine often stores those panels in a leaning tower of chaos: 3 m sheets stacked four deep, cardboard interleaving that shifts, operators “digging” for the right SKU while a €400-per-hour press brake waits idle. The Herochu roll-out rack ends that contradiction. It treats every sheet, frame, guide rail or decorative laminate like a museum artefact while feeding your machines at production-line speed.

Precision storage is not a bigger shelf; it is a different physics. Each 1.2 m-wide tower houses up to twelve steel cradles that extend 100 % on sealed bearings. Push the crank handle—one turn, 30 mm of silent travel—and the chosen drawer glides out until it hovers above the floor, perfectly level with your vacuum lifter. No prying, no walking on piles, no midnight call from the QC inspector who just found a 60 mm gouge across eight panels.

The cradle is the secret. Built from 5 mm Q235 laser-cut plate, it carries 4.5 t yet presents only 12 mm of edge to the sheet above. A replaceable PVC insert runs the full length; under load it compresses 0.3 mm, trapping any rogue chip that might otherwise become a permanent scratch. Need even gentler contact? Swap the strip for felt in under a minute—no tools, no reduction in capacity. For textured laminates we offer UHMW liners rated for 1 Mio. cycles; the coefficient of friction is lower than ice on steel, so 4 m panels slide apart like playing cards.

Elevator profiles are long, and long means leverage. A 6 m stainless sidewall weighs 180 kg but feels twice that when you lift the second end. Our rack lets the crane do the work. Extend the drawer, lower the vacuum beam, engage suction, lift vertically. The sheet never scrapes its neighbour, never twists, never picks up the aluminium oxide that turns into black streaks on a mirror finish. One operator, one minute, zero damage.

Density follows the same logic. A double-sided tower 9 m long stores 42 t of material yet needs only 1.5 m of aisle. Compare that to fixed cantilever racks that demand 3.5 m on both sides and you free 60 % of your floor for value-adding machines. One customer in Naples reclaimed 400 m²—enough to install a new servo press and still park the forklift fleet indoors. Another in Dubai stacked three towers back-to-back, added a 20 m bridge crane, and now feeds two laser lines lights-out.

Growth is bolt-on, not knock-down. Starter bays accept add-on modules with four bolts; expand left, right, or higher without unloading a single sheet. Columns splice at 3 m intervals and arrive pre-milled; fish-plates and hardware are already fitted. Need to store 14 m guide rails? We weld moment joints so deflection at full extension stays under 2 mm—crane operators never notice the gap. Arms adjust on 100 mm pitch; store 40 mm reveal trim one hour and 200 mm structural channel the next.

Control stays deliberately simple. A manual crank with 18:1 reduction lets a 60 kg operator move 4 t without breaking a sweat. Prefer push-button? A 0.75 kW brake motor extends the drawer in 20 seconds and locks it with ±1 mm repeatability. Only one arm can be open at a time—mechanical interlock, no PLC required. If you run an automated crane, photo-eyes shut off travel when a drawer is extended; the signal wires through a common M12 plug, so integration takes minutes, not days.

Safety is engineered, not added later. Each arm carries a three-position detent: closed, vent, 100 % open. A spring-loaded pin prevents accidental roll-out during forklift shocks. The base plate is 12 mm thick and slotted for M20 chemical anchors tested at 72 kN pull-out—enough for seismic zone 4. For high-rise buildings where anchors are forbidden, we supply a 3 m steel spreader frame that distributes load to 2 t per square metre—landlord smiles, permit closed.

Installation respects your uptime. Towers ship in 3 m modules that fit through a standard door. Two fitters, one scissor lift, four hours: the rack is plumb, anchored, and ready for metal. No pit, no fire-suppression upgrade, no civil engineer scratching his head. Relocate? Undo the anchors, sleeve the holes, truck the steel to the next plant; the positional memory stays on the SD card in the hand-wheel encoder.

Return on investment is blunt arithmetic. A 2 m × 1 m hairline-brushed panel costs USD 310; scratch one face and you lose material, labour, and machine time—about USD 450 per incident. Eliminate one rejection per month and the HC-G9055D pays for itself in 10 months. Factor in 1.8 hours saved daily on search time, 25 % denser storage, and the ability to quote just-in-time deliveries, and payback typically lands under 6 months. After that the rack is a profit centre, not a depreciation line.

Elevator passengers will never see the rack, but they will feel the result: doors that open to a flawless mirror, cabins that reflect lights like still water, edges that meet with micrometre precision. Store once, retrieve untouched, install perfection. Herochu roll-out racks turn the chaos of stacked sheets into a vertical library where every page opens without a crease—and that, in the elevator business, is the fastest route to a reputation that rises to the top floor.