Herochu Sheet Racking System with Shelves: Customizable, Safe Storage for Sheet Metal (2025)

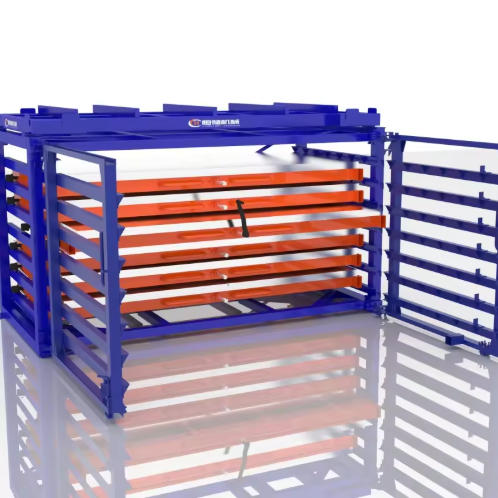

For sheet metal shops, manufacturing facilities, or fabrication yards, disorganized sheet metal storage isn’t just a hassle—it’s a costly risk. Imagine spending hours hunting for a specific aluminum sheet buried under a pile, only to find it scratched beyond use. Or watching a forklift operator struggle to navigate a cramped space, risking a collision that damages both inventory and equipment. Herochu Sheet Racking System with Shelves solves these problems with a design built for strength, accessibility, and space efficiency. Starting at $4,199, fully customizable to your workshop, and backed by CE, UE, and ISO 9001 certifications, this system turns chaotic sheet metal storage into a streamlined, safe asset—whether you’re storing small galvanized sheets or large steel panels.

Why Herochu’s Sheet Racking System Stands Above Generic Storage

Herochu isn’t just a racking brand—it’s a division of Jinan Constant Storage Machinery Manufacturing Co., Ltd., a leader in industrial storage solutions with years of expertise in solving sheet metal handling challenges. What makes our Sheet Racking System with Shelves unique? It’s engineered specifically for the quirks of sheet metal: thin, flat, and prone to scratches or bending if stored haphazardly. Unlike generic shelving that forces you to stack sheets (risking damage) or slide them across rough surfaces (causing scratches), Herochu’s system prioritizes safe access and space optimization.

Whether you have a tiny workshop with limited floor space or a large facility handling high-volume sheet metal, this system adapts. It offers options like roll-out shelves for easy manual access and vertical configurations for tight footprints—so you never have to choose between storage capacity and workflow efficiency. And with a heavy-duty build (designed to handle hundreds of pounds of sheet metal per shelf) and corrosion-resistant finishes, it’s tough enough to withstand the dings, dust, and humidity of industrial environments.

Certified for Safety & Durability: CE, UE, ISO 9001 Standards

When you’re storing sheet metal that’s critical to production—whether it’s 10-gauge steel for structural parts or thin aluminum for electronics—you need a racking system you can trust. Herochu Sheet Racking System with Shelves carries CE, UE, and ISO 9001 certifications—three global benchmarks that guarantee every component, from the steel frames to the roll-out shelf mechanisms, meets strict quality and safety rules. These certifications aren’t just labels: our racks undergo rigorous testing, including weight-load trials (to ensure shelves handle maximum capacity without sagging), scratch-resistance checks (for shelf surfaces), and structural stability tests (to prevent tipping during loading/unloading).

For example, in a food-processing facility using stainless steel sheets, the system’s smooth, easy-to-clean shelves meet hygiene standards. In a construction yard storing weather-exposed metal, the corrosion-resistant finish prevents rust. For any workshop, the certified design means fewer workplace hazards—no more sheets stacked on the floor (a trip risk) or precariously balanced on unstable shelves (a falling hazard). With Herochu, you’re not just buying storage—you’re investing in a system that protects your team, your inventory, and your compliance with industry safety regulations.

Key Features: Built for Sheet Metal’s Unique Needs

Herochu’s Sheet Racking System with Shelves is packed with features that solve the specific frustrations of sheet metal storage. Here’s what sets it apart:

1. Space-Saving Designs for Tight Footprints

If your workshop is short on floor space, you don’t have to sacrifice storage capacity. Herochu offers two space-efficient options:

- Roll-Out Shelves: These shelves slide outward, letting you access sheets from the front without reaching deep into the rack. They eliminate the need for extra aisle space (unlike fixed shelves that require room to reach around), making them perfect for narrow workshops.

- Vertical Racking: For ultra-tight spaces, vertical configurations store sheets upright—turning wasted wall space into usable storage. This design cuts floor space usage by up to 60% compared to horizontal stacking, while still letting forklifts or manual lifters access sheets easily.

2. Customizable to Your Sheet Sizes & Weight Needs

No two sheet metal operations are the same—and your racking should reflect that. Herochu’s system is fully customizable:

- Shelf Sizes: Choose shelf widths and depths to fit your sheets—from small 4x8ft panels to large 10x20ft sheets. We’ll even design extra-wide shelves for oversized materials.

- Weight Capacity: Each shelf can be engineered to handle your load—from 200lbs for thin aluminum sheets to 1,000lbs+ for heavy steel plates. The entire rack can support thousands of pounds, so you never have to worry about overflow.

- Number of Shelves: Add or remove shelves to match your inventory. A 5-shelf system works for small batches, while a 10-shelf setup handles high-volume storage.

- Finishes & Colors: Pick from powder-coated (scratch-resistant) or galvanized (corrosion-resistant) finishes. Choose colors that match your workshop branding—beyond standard blue/orange.

3. Safe, Damage-Free Handling

Sheet metal is easily scratched or bent—and traditional storage makes this worse. Herochu’s system minimizes damage:

- Smooth Shelf Surfaces: No protruding burrs or rough edges that catch on sheets. Shelves are finished to prevent metal-on-metal scratching.

- Roll-Out vs. Sliding: Unlike fixed shelves that require sliding sheets (which causes wear), roll-out shelves bring sheets to you—so there’s no friction or damage during retrieval.

- Easy Access for All Tools: The system is designed to work with your existing equipment—forklifts can reach upper shelves, manual lifters handle lower ones, and even hand access is easy for small sheets. This reduces the need for risky lifting or awkward maneuvering.

How Herochu’s System Solves Your Biggest Sheet Metal Storage Headaches

Let’s face it: sheet metal storage comes with a unique set of frustrations. Herochu’s Sheet Racking System with Shelves fixes them one by one:

1. Eliminates Floor Stacking (and Safety Risks)

Floor-stacked sheets are a double threat: they’re a trip hazard for workers, and they’re prone to water damage or bending. Herochu’s system gets sheets off the floor and onto secure shelves—reducing workplace accidents and keeping inventory in top condition. For facilities that previously stacked sheets 3ft high on the floor, this means a cleaner, safer workspace and fewer workers’ compensation claims.

2. Cuts Retrieval Time (and Boosts Productivity)

Searching for a specific sheet in a pile can take 20+ minutes—time that adds up over a day. Herochu’s system lets you organize sheets by size, material, or project, with clear labeling on each shelf. Roll-out shelves mean you can grab the exact sheet you need in 2 minutes or less. For a shop that retrieves 15 sheets a day, this saves 4+ hours weekly—time your team can spend on fabrication, not hunting for materials.

3. Reduces Material Waste (and Saves Money)

Scratched or bent sheets often end up in the scrap pile—costing you hundreds (or thousands) of dollars annually. Herochu’s smooth shelves and roll-out design minimize damage, so more sheets make it to production. For example, a shop that previously wasted 5% of its sheet metal due to storage damage can cut that to 1%—saving $5,000+ a year on replacement materials.

4. Improves Inventory Tracking

Keeping track of sheet metal stock is tough when it’s stacked randomly. Herochu’s system lets you assign each shelf to a specific material or project, making it easy to count inventory and spot shortages. This prevents last-minute rushes to order more sheets (which cause delays) and ensures you never overstock (which ties up cash).

Industry Applications: Where Herochu’s System Shines

Herochu’s Sheet Racking System with Shelves is built to serve a range of industries that work with sheet metal:

- Fabrication Shops: Stores steel, aluminum, or copper sheets used for custom parts. Roll-out shelves let fabricators quickly grab the right sheet for a project, cutting lead times.

- Automotive Suppliers: Handles thin galvanized sheets for car bodies or heavy steel for frames. Customizable shelf weights ensure the system supports even the heaviest automotive-grade metal.

- Construction Yards: Stores weather-resistant sheets (e.g., corrugated steel) for roofing or siding. Galvanized finishes prevent rust from rain or humidity.

- Electronics Manufacturers: Stores thin aluminum or copper sheets for circuit boards. Smooth shelves prevent scratches that could damage sensitive components.

- Food Processing Plants: Uses stainless steel-compatible shelves to store food-grade sheet metal (e.g., for equipment panels). Easy-to-clean surfaces meet hygiene standards.

Why Herochu’s System Is a Smart Investment (Starting at $4,199)

In a year where efficiency and cost-saving matter more than ever, Herochu’s Sheet Racking System with Shelves offers clear ROI:

- Lower Waste Costs: Reducing sheet damage by 4% (as in the example above) saves $5,000+ annually—enough to cover the rack’s cost in a year.

- Faster Production: Cutting retrieval time by 4 hours weekly frees up your team to take on more projects—boosting revenue by 10–15%.

- Reduced Safety Costs: Fewer accidents mean lower workers’ compensation claims and insurance premiums.

- Future-Proofing: Customizable design means the system grows with your business. Add shelves or expand capacity as your sheet metal needs increase—no need to buy a new rack.

How to Get Started with Herochu

Ready to turn chaotic sheet metal storage into a streamlined, safe process? Here’s how to begin:

- Schedule a Workshop Assessment: Our engineers will visit your facility (or do a virtual tour) to measure your space, assess your sheet sizes/weights, and understand your workflow (e.g., how often you retrieve sheets, what tools you use).

- Customize Your System: We’ll design a solution that fits—whether you need a 5-shelf roll-out system for 4x8ft aluminum sheets or a 10-shelf vertical system for 10x20ft steel plates. We’ll recommend finishes (e.g., galvanized for outdoor use) based on your environment.

- Fast Delivery & Installation: Our team delivers and installs the system quickly, with minimal disruption to your operations. We’ll train your team to use the rack safely, label shelves for inventory tracking, and test the roll-out mechanisms to ensure smooth operation.

Herochu Sheet Racking System with Shelves isn’t just a storage solution—it’s a way to make your sheet metal operation more efficient, safer, and more profitable. Whether you’re a small fabrication shop or a large automotive supplier, we’ll help you design a system that fits your budget, your space, and your sheets. Contact Jinan Constant today to get a custom quote and take the first step toward stress-free sheet metal storage.