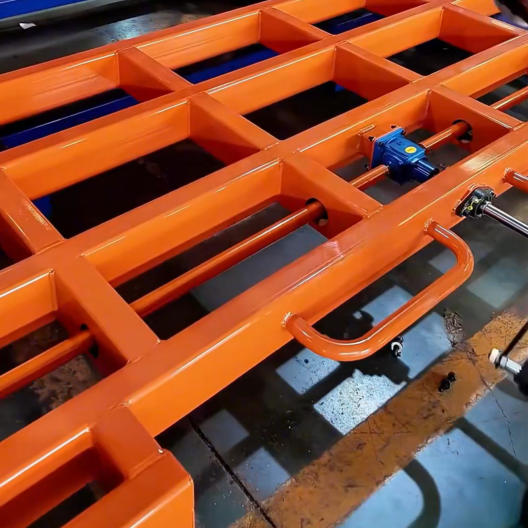

Roll-Out Sheet Racks for storing sheet steel

Herochu’s Roll-Out Sheet Racks are engineered to optimize material flow, reducing downtime and increasing productivity. The roll-out feature allows for quick and easy access to stored materials, eliminating the need to sift through stacks or rearrange items. This design ensures that operators can retrieve materials swiftly, whether they’re using overhead cranes or manual handling methods.

Herochu Roll-Out Sheet Racks: The Ultimate Storage Solution for Sheet Steel

Introduction

In the fast-paced world of metal fabrication and manufacturing, efficient storage and retrieval of sheet steel, aluminum, and other flat products are critical to maintaining productivity and workflow. Herochu’s Roll-Out Sheet Racks are designed to meet these challenges head-on, offering a safe, dependable, and highly customizable storage solution that streamlines material flow and enhances overall operational efficiency. With CE, UE, and ISO 9001 certifications, Herochu’s Roll-Out Sheet Racks are built to meet the highest international standards, ensuring reliability and performance in any industrial environment.

Why Choose Herochu Roll-Out Sheet Racks?

Enhanced Material Flow and Accessibility

Herochu’s Roll-Out Sheet Racks are engineered to optimize material flow, reducing downtime and increasing productivity. The roll-out feature allows for quick and easy access to stored materials, eliminating the need to sift through stacks or rearrange items. This design ensures that operators can retrieve materials swiftly, whether they’re using overhead cranes or manual handling methods.

Customizable to Your Workshop Needs

Understanding that every workshop has unique requirements, Herochu offers fully customizable Roll-Out Sheet Racks. Starting at $4,200, these racks can be tailored to fit your specific material sizes, storage capacity, and facility layout. Whether you’re storing sheet steel, aluminum, or other flat products, Herochu’s solutions can be adapted to meet your exact needs, ensuring maximum space utilization and efficiency.

Safety and Durability

Safety is a top priority in any industrial setting. Herochu’s Roll-Out Sheet Racks are built with heavy-duty materials and robust construction, ensuring the safety of your team and the integrity of your materials. The racks are designed to prevent material damage and drooping, while also keeping sharp edges and corners safely contained, reducing the risk of workplace injuries.

Standard Roll-Out Sheet Rack Models

Herochu offers a range of standard Roll-Out Sheet Rack models, each designed to cater to different storage requirements. Here’s a detailed look at our standard models:

HC-B2015-62

- Plate Size: 2000x150mm

- Drawer Capacity: Up to 5,000 lbs

- Number of Drawers: 4-8

- Rack Height: 73-81 inches

- Drawer Spacing: 4-12 inches apart

HB-B3015-65

- Plate Size: 3000x1500mm

- Drawer Capacity: Up to 5,000 lbs

- Number of Drawers: 4-8

- Rack Height: 73-81 inches

- Drawer Spacing: 4-12 inches apart

HB-B6015-63

- Plate Size: 6000x1500mm

- Drawer Capacity: Up to 5,000 lbs

- Number of Drawers: 4-8

- Rack Height: 73-81 inches

- Drawer Spacing: 4-12 inches apart

HC-B6020-65

- Plate Size: 6000x2000mm

- Drawer Capacity: Up to 5,000 lbs

- Number of Drawers: 4-8

- Rack Height: 73-81 inches

- Drawer Spacing: 4-12 inches apart

Features and Benefits

Increased Vertical Storage Density

Herochu’s Roll-Out Sheet Racks are designed to maximize vertical storage space, allowing you to store more materials in a smaller footprint. This feature is particularly beneficial for workshops with limited floor space, enabling you to optimize your storage area and improve overall organization.

Classified Material Management

Our racks facilitate quick and easy classification of materials by size, type, gauge, and material type. This organized approach ensures that materials are always accessible when needed, reducing search time and minimizing disruptions to your workflow.

Steady Structure with Heavy Loading Capacity

Each drawer in Herochu’s Roll-Out Sheet Racks is engineered to handle heavy loads, with a maximum capacity of 5,000 lbs per drawer. The robust construction ensures stability and safety, even when drawers are fully loaded.

Fork Pockets Design for Easy Forklift Access

The fork pockets design allows for seamless integration with your existing forklift fleet. Operators can easily insert forks into the designated channels, enabling quick and efficient loading and unloading of materials.

Single-Person Operation

Herochu’s Roll-Out Sheet Racks are designed for single-person operation, reducing labor costs and improving efficiency. Whether you’re using an overhead crane or manual handling methods, one operator can safely and easily manage the entire process.

Material Protection

Our racks are designed to protect your materials from damage and drooping. The secure storage system ensures that materials remain in optimal condition, reducing waste and maintenance costs.

Worker Safety

Herochu’s Roll-Out Sheet Racks prioritize worker safety by keeping sharp edges and corners safely contained. This design minimizes the risk of injuries, creating a safer work environment for your team.

Standard Models and Specifications

For a more detailed overview, here are the specifications for Herochu’s standard Roll-Out Sheet Rack models:

48X96R

- Drawer Capacity: 5,000 lbs

- Rack Length (C): 111 inches

- Rack Width (D): 103 inches

- Drawer Length (E): 98 inches

- Drawer Width (F): 50 inches

- Rollout Extension (C): 56 inches

48X120R

- Drawer Capacity: 5,000 lbs

- Rack Length (C): 135 inches

- Rack Width (D): 103 inches

- Drawer Length (E): 122 inches

- Drawer Width (F): 50 inches

- Rollout Extension (C): 56 inches

60X120R

- Drawer Capacity: 5,000 lbs

- Rack Length (C): 135 inches

- Rack Width (D): 127 inches

- Drawer Length (E): 122 inches

- Drawer Width (F): 62 inches

- Rollout Extension (C): 68 inches

72X144R

- Drawer Capacity: 5,000 lbs

- Rack Length (C): 159 inches

- Rack Width (D): 151 inches

- Drawer Length (E): 146 inches

- Drawer Width (F): 74 inches

- Rollout Extension (C): 80 inches

Frequently Asked Questions

What kind of handling equipment do I need to operate these racks?

Herochu’s Roll-Out Sheet Racks are designed for versatility and can be operated with a variety of handling equipment, including standard forklifts, overhead bridge cranes, jib cranes, and gantry cranes. For crane operation, you would typically use accessories like vacuum lifters or plate clamps to handle the sheets.

Can one person safely operate a rack with heavy materials, like 5,000 lbs?

Yes, for loads of this weight, Herochu recommends their hand-cranked model. The geared crank mechanism makes it easy and safe for a single operator to smoothly roll out a fully loaded drawer without physical strain.

How do I load new sheets onto the rack drawers?

Loading is straightforward. For forklift-operable models, you can place a stack of sheets directly onto the drawer/pallet. For all models, you can use your crane or forklift to place sheets onto an extended drawer. Herochu also offers specialized accessories like a “Depalletizer” to help safely transfer a full stack of material from a wooden shipping pallet to their steel drawer.

Can the racks be customized for my specific sheet sizes and weight needs?

Yes, customization is one of Herochu’s core strengths. They can engineer the sheet steel storage rack dimensions, number of levels, drawer capacity, and even color to perfectly match your material specifications, available space, and existing handling equipment capabilities.

What is the maximum height for these storage racks?

The height is primarily limited by your facility’s ceiling height and the maximum lift height of your handling equipment (forklift or crane). Herochu has successfully implemented systems with up to 20 levels. Their engineers will work with you to design a system that maximizes your vertical space while ensuring safe and efficient operation.

Conclusion

Herochu’s Roll-Out Sheet Racks are the ultimate storage solution for sheet steel, aluminum, and other flat products. With their customizable design, enhanced material flow, and commitment to safety and durability, these racks are an investment in your workshop’s efficiency and productivity. Whether you’re looking for one unit or a fully integrated storage and handling system, Herochu has the experience, skill, and creativity to analyze your application and meet your specific requirements. Contact us today to learn more about how Herochu’s Roll-Out Sheet Racks can revolutionize your material storage and handling processes.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Automated Sheet Metal Storage Systems

Heavy Duty Sheet Metal Forklift Solutions

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Forklift for Metal Sheets – Efficient Handling Solutions

Read moreRated 0 out of 5