Heavy Duty sheet metal Rolling Storage Racks

The heart of the system is a single roll-out cradle rated for three to six tonnes per shelf. Instead of levering a 4 m × 2 m sheet off a stack with a fork and a prayer, an operator extends the drawer, drops a magnet or vacuum lifter, and walks away. The drawer locks in place while open and locks again when closed, so vibration from the neighbouring press brake never starts a slow-motion avalanche. One person, one handle, thirty seconds—no second forklift, no spotter, no overtime.

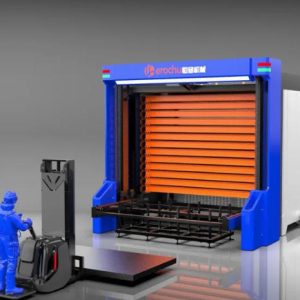

Herochu Heavy-Duty Sheet Metal Rolling Storage Racks

Park 30 tonnes of plate in a footprint smaller than a family car, pull each drawer out like a kitchen tray, and still have room left for tomorrow’s rush job. Starting at five thousand dollars and CE/UE/ISO 9001 certified, these racks are built for shops that measure floor space in euros, minutes and scratched paint.

Park 30 tonnes of plate in a footprint smaller than a family car, pull each drawer out like a kitchen tray, and still have room left for tomorrow’s rush job. Starting at five thousand dollars and CE/UE/ISO 9001 certified, these racks are built for shops that measure floor space in euros, minutes and scratched paint.

The heart of the system is a single roll-out cradle rated for three to six tonnes per shelf. Instead of levering a 4 m × 2 m sheet off a stack with a fork and a prayer, an operator extends the drawer, drops a magnet or vacuum lifter, and walks away. The drawer locks in place while open and locks again when closed, so vibration from the neighbouring press brake never starts a slow-motion avalanche. One person, one handle, thirty seconds—no second forklift, no spotter, no overtime.

Stock heights start at five usable drawers plus a sixth “roof” level for remnants, but the modular frame accepts extra bays the same way a server rack accepts blades. HC-B3015-63 keeps things compact: 3 m × 1.5 m sheets, 3 t per drawer, 3.5 m overall width—perfect for a single laser cell. Step up to HC-B6020-66 and the rack swallows 6 m × 2 m plate at 6 t per shelf while staying under 2.3 m high so it still clears a standard roller door. Need seven levels? 450 mm pitch instead of 220 mm? A 60 mm ground clearance for pallet truck entry? The laser cutting, robot welding and machining all happen in-house, so the conversation starts with “what do you need?” rather than “what do we stock?”

The load path is refreshingly over-built. Drawer side rails are 8 mm laser-cut steel, induction hardened to 42 HRC and running on sealed cam followers with 20 mm axles. When a 5 t coil set is rolled in, the deflection measured at full extension is under 1 mm—low enough that the sheet lifter never loses suction. Columns are 250 mm box sections, diagonally braced, anchored with M24 chemical studs and tested to 1.25 × rated load. The powder coat is RAL 7035 as standard, but we keep orange, yellow and steel-blue on tap so the rack matches your corporate colours or safety zones.

Space savings arrive the moment the first drawer closes. A typical block-stack of 25 t of mixed plate needs roughly 120 m² once you include the approach aisle. Three HC-B4020-65 islands store the same tonnage in 24 m² and leave a 3 m drive-through lane for the forklift. At €12 per square metre per month, the rent you stop paying funds the entire purchase in under ten months—everything after that is margin.

Inventory chaos fades just as fast. Each drawer face accepts a magnetic label strip and a barcode pocket. Scan the code, extend the drawer, pull the sheet—no more climbing over 8 mm plate to discover the 2 mm you actually need is at the bottom. Remnants live on the top deck, divided by movable pins, so off-cuts stay visible instead of becoming expensive scrap.

Safety officers like the details that never appear on a price list. Drawers roll on eccentric cams that drop 3 mm when locked, preventing coasting. A mechanical stop prevents over-travel even if someone confuses muscle with leverage. The leading edge of every arm is bevelled and plastic-capped so shin meets polymer, not steel. Ground clearance is 355 mm—high enough for a pallet truck, low enough that nobody ducks under a beam. Fork pockets are built into the base frame for relocation, but they double as impact absorbers when a driver gets too close.

Integration with existing machinery is plug-and-play. Position the rack perpendicular to a laser gate and the drawer height matches the shuttle table; one person transfers sheet without a second vacuum lift. Place it beside a shear and the top deck becomes a staging table for blanks. Add roller conveyors to the drawer throat and the rack becomes an in-feed magazine for an automated panel bender. We have supplied racks with pop-up transfers, weigh cells and even RFID antennas that update MRP the moment a sheet is loaded or removed.

Maintenance is minimal because bearings are sealed for life and columns are closed sections—nowhere for swarf to collect. A monthly wipe of the rails and a squirt of dry-film PTFE keeps the action glass-smooth. Should an arm ever be damaged by a rogue fork, it unbolts in two minutes and a replacement bolts on. No cutting, no welding, no production shutdown.

Environmental credentials are baked in. Steel contains 30 % recycled content and is 100 % recyclable at end-of-life. By eliminating the need for timber dunnage and reducing forklift mileage, each rack saves roughly 4 t of CO₂ per year—numbers that feed straight into your sustainability report. When the lease ends, unbolt the anchors and the entire structure moves to the next facility, leaving only four holes to grout.

Ordering is a conversation, not a catalogue. Send a list: sheet sizes, max pack weight, how many packs, ceiling height, forklift reach. We return a 3D STEP model, load diagram, anchor plan and firm price within 24 h. Approval drawings are stamped by a registered engineer and locked; production starts the same afternoon. Standard lead time is fifteen working days; custom colours or special pitches add three. Every rack ships pre-assembled on steel feet, wrapped in shrink film and mounted on timber runners so a standard forklift can unload without an awkward container ramp.

The guarantee is blunt: install the rack, use it for ninety shifts. If it does not save you at least one paid hour per week, we pick it up and refund the full purchase price including freight. No restock fee, no argument, no fine print. That promise has been tested twice in the last three years; both times the customer kept the rack and sent photos of the extra coffee breaks instead.

Stop carving walking paths between leaning plates. Give every sheet a drawer that opens like a filing cabinet, locks like a safe and moves like silk. Herochu heavy-duty rolling storage racks turn the area beside your laser, shear or press brake into the quietest square metre in the shop—because the only thing left on the floor is clean concrete and the next job already queued.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty cantilever sheet metal rack

Read moreRated 0 out of 5