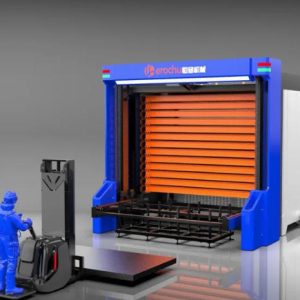

Herochu Heavy-Duty Rolling Sheet Rack

Stop Gambling With Safety: End Unsafe Metal Storage For Good

A leaning stack of steel is not a storage method—it is a slow-motion accident. Every time someone pries out the bottom sheet, gravity waits for one wrong footstep, one tired sling, one moment of crossed signals. Herochu drawer-style racks remove the gamble by giving each plate its own pull-out cradle. No climbing, no crowbars, no three-man ballet with a overhead crane. One operator, one handle, one smooth roll—and the load you need is fully exposed, fully supported, fully safe.

The math is brutal but simple: a 3 t bundle dropping half a metre generates 15 kN of impact, enough to fracture concrete and end a career. Our racks stop that drop before it starts. Each drawer extends 100 % on sealed steel rollers, locks positively in place, and presents the entire face of the sheet to a magnet, vacuum lifter or forklift. The stack never tilts, the operator never reaches overhead, and the sling never has to hunt for balance.

Built to break the accident chain

HC-B3015-63 holds 3 m × 1.5 m plate at 3 t per shelf—six drawers plus a top remnant level in a footprint smaller than a family car. Step up to HC-B6020-66 and you store 6 m × 2 m sheets at 6 t each while staying under 2.3 m high so you keep clear of fire-sprinkler heads and crane hooks. Arm spacing is calculated to the millimetre: half the sheet length supported, deflection limited to 1 mm under full load, so even thin aluminium will not oil-can between arms.

The frame is 8 mm laser-cut structural steel, robot-welded, then powder-coated RAL 7035 at 80 µm. Columns are 250 mm closed box sections, diagonally braced, anchored with M24 chemical studs tested to 1.25 times rated capacity. Rollers are induction-hardened to 42 HRC and run inside replaceable guide cartridges—if a fork ever kisses the rail, you swap a cartridge, not the whole rack.

Ergonomics that protect the second victim: your wallet

Musculoskeletal injuries do not make the evening news, but they devour margins. Pulling a 40 kg sheet from the middle of a stack generates 900 N of shear on the lumbar spine—day after day until the MRI bill arrives. Herochu racks reduce that force to zero. A low-ratio hand-crank option lets an operator roll out 3 t with 15 N of handle force; motor-drive kits handle 6 t at the press of a green button. Either way, the back, shoulders and wrists stay out of the danger zone, and the comp adjuster stays off your porch.

Forklift drivers win, too. Because the drawer front sits only 355 mm above the floor, forks enter at the natural angle—no teetering on 4×4 blocks, no blind stabbing under a bent sheet. The leading edge of every arm is bevelled and capped with replaceable UHMW plastic so even polished stainless leaves without a scratch. When the shift ends, drawers lock closed with a keyed lever, preventing unauthorised access and stopping the late-night “quick borrow” that ends in a domino topple.

Space you can measure in rent receipts

Traditional block-stacking eats floor for breakfast. Twenty-five tonnes of mixed plate typically occupies 120 m² once you include the approach aisle. Three HC-B4020-65 islands store the same tonnage in 24 m² and still leave a 3 m drive-through. At €12 per square metre per month, that is €14 400 per year you no longer pay to a landlord—enough to finance the racks before the next tooling invoice lands. When the lease expires, unbolt the anchors and wheel the entire structure to the new building; the only footprint left is four holes the size of a thumbnail.

Traceability that satisfies auditors and insurers

Each drawer ships with a laser-etched data plate: arm capacity, column capacity, heat number, powder-batch and test date. A QR code links to a PDF pack—mill certificates, weld maps, static-load report, anchor pull-out test, even the torque spec for the floor bolts. Safety inspectors see paperwork first, steel second; we deliver both before you ask. CE conformity covers EN 1090-1 execution class EXC 2, and the system is pre-approved for seismic zones up to 0.3 g when knee-braces are fitted.

Accessories that turn storage into a process

Bolt-on sensor plates tell an AGV which drawers are free. RFID antennas embedded in the arm lip update MRP the moment a sheet lands. LED light bars glued to the throat switch on when the drawer extends, giving camera systems the contrast they need for automated picks. Nylon liners, copper-free pads for stainless, or rubber matting for polished aluminium all clip on without drilling. If tomorrow’s product is heavier, longer, or hotter, unbolt the arms, slide in new ones, and the rack evolves as fast as your market.

Maintenance you can calendar in pencil

Bearings are sealed for life; rails are closed sections—nowhere for swarf to collect. A monthly wipe with a dry cloth and a squirt of PTFE spray keeps the action glass-smooth. Damage an arm? Four bolts and it drops out; a replacement bolts in while the kettle boils. No hot-work permit, no cutting disc, no production shutdown. Expected life is 25 years at one shift per day, but we have racks in galvanising plants that have seen 40 000 cycles and still measure within original tolerance.

Guarantee that puts money where the mouth is

Install the rack, use it for ninety shifts. If it does not save you at least one paid hour per week, we pick it up and refund 100 %—including freight. No restock fee, no argument, no fine print. That promise has been invoked twice; both times the customer kept the rack and sent photos of the extra coffee breaks instead.

Stop measuring safety in luck. Replace the wobble of stacked plate with the calm click of a locked drawer, and let gravity keep its weight while you keep your people. Herochu heavy-duty rolling racks: every sheet in its place, every shift without incident, every cent of rent back in your pocket.