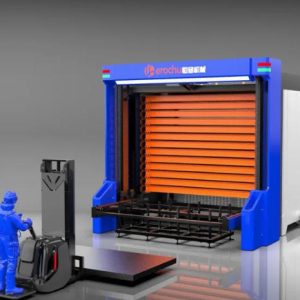

Steel plate rack for workshop yard

Heavy plates hate being horizontal. They warp, scratch and camouflage themselves under dust. Herochu stands them on edge inside a welded 8 mm steel cartridge that rides on sealed bearings. Pull the handle: the tray glides to full extension, locks, and presents the sheet at the exact height of your hoist. Push it home and the latch clicks without pins or thought. The frame is cut from one-piece 100 × 100 × 5 mm tube, shot-blasted to SA 2.5 and finished in marine-grade powder-coat that shrugs off weld spatter. If your yard is open to the weather we hot-dip the whole skeleton and throw in stainless bearings.

Herochu Steel-Plate Rack

Workshop yard | Drawer-style | From $4 399 | CE & ISO 9001

Workshop yard | Drawer-style | From $4 399 | CE & ISO 9001

Store, protect and feed sheet metal faster than your lasers can gulp it. The HC-B drawer rack condenses up to 200 plates into a single square of floor space the size of two pallets, yet a lone operator can slide out a 5 500 lb tray, drop a vacuum lifter, and be gone in under ten seconds. No leaning tower of rusting sheets, no splintered dunnage, no hunt-and-peck inventory.

Heavy plates hate being horizontal. They warp, scratch and camouflage themselves under dust. Herochu stands them on edge inside a welded 8 mm steel cartridge that rides on sealed bearings. Pull the handle: the tray glides to full extension, locks, and presents the sheet at the exact height of your hoist. Push it home and the latch clicks without pins or thought. The frame is cut from one-piece 100 × 100 × 5 mm tube, shot-blasted to SA 2.5 and finished in marine-grade powder-coat that shrugs off weld spatter. If your yard is open to the weather we hot-dip the whole skeleton and throw in stainless bearings.

Density is where the invoice speaks. A conventional stack of 4 × 2 m plates eats thirty-two square metres; one HC-B4020 rack swallows the same pile in four and a half. At average European warehouse rent that is sixteen hundred euros back in your pocket every year, per rack, forever. Add the soft savings—zero edge damage, thirty percent faster change-overs, half the lifting injuries—and most shops recoup the ticket price before the warranty even starts.

The cartridge is also a shipping box. When the tray is empty your supplier forks it onto the return lorry, refills it at the mill, and sends it back—no pallets, no stretch-wrap, no disposal cost. Customers report six percent off material price because vendors love reusable packaging as much as you do.

Standard footprints begin at three metres long and climb to six, with shelf loads from three to six tonnes. Need eight metres, ten tonnes, double-sided access, or RFID tagging? Send a sketch; we will cut custom uprights overnight and deliver in under three weeks. Every rack arrives knocked-down in a steel export crate that doubles as its own stillage. Two people, one wrench, ninety minutes and the unit is anchored and level, ready for plates before lunch.

CE marking, TÜV-audited ISO 9001 and full FEM static analysis are included, not upsold. A ten-year structural warranty covers the frame and shelving; bearings and latches are classed as wear parts and ship from stock in Rotterdam, Chicago or Dubai within forty-eight hours. Scan the riveted QR code for assembly videos, lubrication charts and spare-part numbers. If you prefer human eyes we will put a technician on a plane inside seventy-two hours, anywhere on the map.

Stop paying rent to a pile of steel. Turn the weakest link in your workflow—storage—into the fastest. Request a drawing today, load plates next week, and start mornings calm for a change.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Material Handling Equipment

Steel Plate Lifting Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Industrial Sheet Metal Manipulator lifting equipment

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Sheet Metal storage racking systems

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Warehouse Inventory Management System and Automatic Plate Storage Tower for Laser Machine

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty cantilever sheet metal rack

Read moreRated 0 out of 5