Automatic Pipe Storage Racks Automated Profile Storage Warehouse Systems

The Herochu automated system is not merely a rack but a complete, integrated storage and retrieval ecosystem. It comprises a sophisticated loading and unloading gantry system, high-density profile material racks, heavy-duty material frames, and precision-engineered guide rails. This cohesive unit functions as a single, intelligent organism designed to manage your inventory with robotic accuracy. The main structure is fabricated from high-grade steel, granting it an exceptional load-bearing capacity that is both sturdy and durable. It is engineered to store single or bundled profiles of varying types, weights, and lengths simultaneously. Crucially, the entire system—including the number of rack layers and the overall storage quantity—is fully customizable to the specific dimensions and volume requirements of your factory, ensuring a perfect fit for your unique operational workflow.

Herochu Automatic Pipe Storage Racks: The Pinnacle of Automated Profile Storage Warehouse Systems

In the landscape of industrial manufacturing and warehousing, the storage and retrieval of long, heavy profiles—including steel pipes, tubing, aluminum extrusions, and structural beams—represent a significant operational bottleneck. Traditional manual methods are not only time-consuming and labor-intensive but also prone to inefficiency, inventory inaccuracy, and heightened safety risks. Herochu addresses these critical challenges with a groundbreaking solution: our fully Automated Profile Storage Warehouse Systems. This state-of-the-art infrastructure represents a transformative investment in operational autonomy, precision, and density, engineered for facilities demanding unparalleled efficiency. With systems starting at $42,000, Herochu automation is a scalable and strategic asset for the modern warehouse.

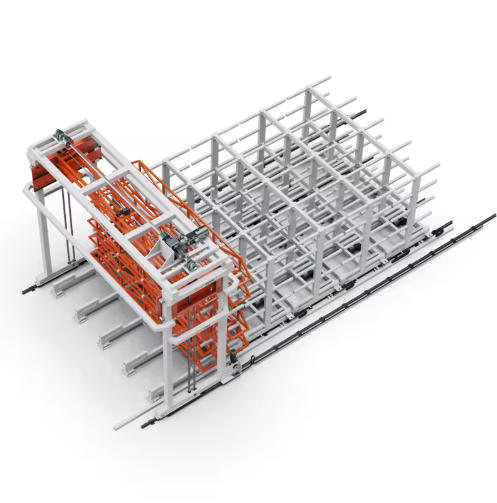

The Architecture of Automation: A Fully Integrated System

The Herochu automated system is not merely a rack but a complete, integrated storage and retrieval ecosystem. It comprises a sophisticated loading and unloading gantry system, high-density profile material racks, heavy-duty material frames, and precision-engineered guide rails. This cohesive unit functions as a single, intelligent organism designed to manage your inventory with robotic accuracy. The main structure is fabricated from high-grade steel, granting it an exceptional load-bearing capacity that is both sturdy and durable. It is engineered to store single or bundled profiles of varying types, weights, and lengths simultaneously. Crucially, the entire system—including the number of rack layers and the overall storage quantity—is fully customizable to the specific dimensions and volume requirements of your factory, ensuring a perfect fit for your unique operational workflow.

Operational Excellence: Precision, Speed, and Reliability

At the heart of the Herochu Automated Storage System is its meticulously engineered motion system. Movement is facilitated by a combination of robust linear guide rails and a powerful chain drive transmission. This ensures smooth, precise, and reliable positioning of the gantry, eliminating the sway and imprecision associated with lesser systems. The vertical lifting speed operates at a efficient 9 meters per minute, while the inlet and outlet speed for material handling reaches 12 meters per minute. These calibrated speeds are optimized for rapid cycle times without sacrificing the pinpoint accuracy required for safe handling of valuable materials. The system’s logic is designed for seamless operation, automatically navigating to the designated storage location, retrieving the specified profile, and delivering it to the workstation—all without human intervention in the storage aisle.

Unrivaled Benefits for the Modern Enterprise

Implementing a Herochu Automated Profile Storage Warehouse System yields immediate and profound benefits across your operation. The most significant advantage is the dramatic reduction in labor costs and reliance on manual labor, particularly that of forklift operators for high-reach tasks. This simultaneously enhances workplace safety by removing personnel from potentially hazardous material handling processes. Inventory control is revolutionized; with integrated software, every item’s location is tracked digitally, enabling perfect inventory accuracy, rapid auditing, and optimized space utilization that can increase storage capacity by multiples compared to traditional racking. The system operates relentlessly during extended shifts, boosting overall throughput and ensuring that production lines are supplied with materials without delay, thereby maximizing equipment uptime and overall productivity.

Technical Specifications and Customization

The Herochu HC-S6020 model exemplifies our engineering prowess, but it is merely a starting point for customization.

-

Standard Specifications: The system is designed for profiles with standard lengths of 6015mm, 6020mm, or 6025mm. The number of floors (levels) typically ranges from 8 to 13, with a load capacity of 3 or 5 tons per layer.

-

Core Components: The system is constructed from Q235 steel, ensuring structural integrity. The transmission is a dependable chain drive, and movement is guided by linear rails and chain.

-

Customization Options: The loading capacity is highly flexible, customizable from 1,000 kg up to an impressive 10,000 kg per layer to suit even the heaviest industrial materials. The profile support mechanism can be optionally selected to accommodate specific material shapes and prevent deformation.

-

Finish and Warranty: The surface receives a durable powder-coated finish for corrosion resistance, and the color can be customized to align with corporate branding. Each system is backed by a comprehensive 1-year warranty, reflecting our confidence in its build quality and performance.

A Strategic Investment in Your Operational Future

The Herochu Automatic Pipe Storage Rack is more than a piece of equipment; it is the core of a smarter, safer, and more profitable warehouse. It is the definitive solution for businesses in metal service centers, pipeline distribution, and large-scale fabrication looking to achieve a competitive edge through automation. By automating the most cumbersome aspect of material handling, you reallocate human capital to more value-added tasks, mitigate risk, and establish a foundation for scalable growth.

Take the first step toward redefining your warehouse operations. Contact a Herochu automation specialist today to schedule a consultation. We will analyze your specific profile storage requirements and provide a detailed, customized proposal for a system engineered to deliver a rapid return on investment through unmatched efficiency and reliability.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.