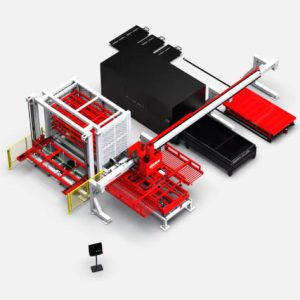

Loading & Unloading Equipment Servo swing arm handling manipulator

Industrial robots have redefined how businesses approach repetitive, labor-intensive tasks—and Herochu’s manipulator stands out for its focus on practicality and reliability. Unlike generic loading & unloading equipment, this servo-driven system is built to replace manual workpiece classification, transportation, and stacking—even in high-risk environments. Whether your team handles radioactive materials, toxic substances, or heavy sheet metal, the manipulator eliminates direct human exposure, drastically reducing labor intensity and ensuring compliance with strict workplace safety standards.

Specification

|

STANDARD

|

HC-R3015-500

|

HC-R3015-750

|

HC-R3015-1000

|

HC-R4020-500

|

HC-R4020-750

|

|

Thickness of feeding plate

|

8mm

|

12mm

|

20mm

|

8mm

|

12mm

|

|

Maximum feeding width

|

3000*1500mm

|

4000*2000mm

|

|||

|

Minimum feeding width

|

1250*1000mm

|

1250*1000mm

|

|||

|

Maximum plate weight

|

300kg

|

500kg

|

1000kg

|

300kg

|

500kg

|

|

Number of suction cups

|

15

|

15

|

118

|

15

|

15

|

|

Suction cup diameter

|

150mm

|

200mm

|

250mm

|

150mm

|

200mm

|

|

Power mode

|

Electric

|

||||

Herochu Servo Swing Arm Handling Manipulator: Elevate Industrial Loading & Unloading with Precision Automation

In today’s fast-paced manufacturing landscape, industrial automation isn’t just a luxury—it’s a necessity to stay competitive. Herochu’s Servo Swing Arm Handling Manipulator emerges as a game-changing solution for loading & unloading equipment needs, designed to streamline operations, enhance safety, and cut costs across sheet metal, laser cutting, and warehousing sectors. As a leader in industrial robotics, Herochu engineers this manipulator to meet the unique demands of modern workshops, offering full customization, industry-leading certifications, and performance that directly translates to faster production cycles and reduced labor strain.

Why Choose Herochu’s Servo Swing Arm Handling Manipulator?

Industrial robots have redefined how businesses approach repetitive, labor-intensive tasks—and Herochu’s manipulator stands out for its focus on practicality and reliability. Unlike generic loading & unloading equipment, this servo-driven system is built to replace manual workpiece classification, transportation, and stacking—even in high-risk environments. Whether your team handles radioactive materials, toxic substances, or heavy sheet metal, the manipulator eliminates direct human exposure, drastically reducing labor intensity and ensuring compliance with strict workplace safety standards.

Beyond safety, the manipulator delivers tangible efficiency gains. In sheet metal warehousing, for example, throughput is directly tied to how quickly and accurately materials are moved. Herochu’s system excels here: its precision engineering ensures consistent handling of sheets, minimizing damage and reducing downtime caused by human error. For laser cutting operations, it seamlessly integrates with up to three workstations, keeping machines fed and operational without gaps—critical for meeting tight production deadlines.

Customized to Your Workshop, Starting at $20,200

Every workshop has unique needs, and Herochu refuses to force a one-size-fits-all solution. Our Servo Swing Arm Handling Manipulator is fully customizable, tailored to your space, workflow, and material requirements. Whether you need adjustments to reach, load capacity, or integration with existing equipment (like manual sheet material libraries), our team works with you to design a system that fits your operation—not the other way around. This flexibility means you only pay for the features you need, with pricing starting at $20,200—an investment that quickly pays off through reduced labor costs and increased output.

Industry-Leading Certifications: CE, UE, ISO 9001

Trust is non-negotiable when it comes to industrial equipment, which is why Herochu’s Servo Swing Arm Handling Manipulator holds CE, UE, and ISO 9001 certifications. These credentials validate that every unit meets rigorous international standards for quality, safety, and performance. ISO 9001 ensures consistent manufacturing processes, while CE and UE certifications guarantee compliance with European health, safety, and environmental regulations—making the manipulator suitable for global operations, whether you’re based in Europe, North America, or Asia.

Technical Specifications: Built for Performance & Durability

Herochu’s commitment to precision is reflected in every technical detail of the Servo Swing Arm Handling Manipulator. Designed as a multi-station solution (also referred to as a Column Robot or Linear Robot), it balances power with agility, making it ideal for sheet metal and laser cutting applications. Here’s a breakdown of its key specs:

- Axis Configuration: 3-axis design for smooth, multi-directional movement, ensuring coverage of even complex work areas.

- Positioning Accuracy: ±0.5mm—critical for handling delicate or high-precision materials where even small deviations can cause waste.

- Repeatability: ±3mm, guaranteeing consistent performance across thousands of cycles, eliminating variability in production.

- Maximum Speed: 25m/min, enabling fast material transfer to keep up with high-volume operations.

- Carrying Capacity: Up to 150KG, supporting heavy sheet metal and components without compromising stability.

- Work Scope: 3000mm–48000mm, offering extensive reach to cover large workstations or warehousing areas.

- Sheet Thickness Compatibility: Handles sheets from 0.5mm (thin, delicate materials) to 4mm (thick, heavy-duty stock), versatile enough for diverse applications.

- Power & Air Supply: Operates on 220V 50HZ/60HZ (compatible with global power standards) and requires 0.55MPa air pressure for pneumatic components.

- Machine Weight: 700KG—sturdy enough for heavy loads, yet compact to minimize floor space.

Key Advantages: Designed for Operational Ease

Herochu’s Servo Swing Arm Handling Manipulator isn’t just powerful—it’s also easy to integrate and maintain, ensuring minimal disruption to your workflow:

- Small Footprint: Compact design means it fits into tight workshop spaces, even in facilities with limited floor area.

- Simple Structure & Strong Load Capacity: Robust construction supports up to 150KG, while a streamlined design reduces the risk of mechanical failure.

- Easy Maintenance & Operation: Intuitive controls mean your team can learn to operate it quickly, and a simplified mechanical system reduces maintenance time and costs.

- Multi-Station Support: Serves up to three workstations, eliminating the need for multiple pieces of loading & unloading equipment.

- Standard Automatic Splitting System: Ensures precise separation of stacked sheets, reducing jams and improving efficiency.

- Compatibility with Manual Sheet Libraries: Integrates seamlessly with existing manual storage systems, making it easy to upgrade without replacing your current setup.

Conclusion: Invest in Automation That Drives Results

Herochu’s Servo Swing Arm Handling Manipulator is more than just loading & unloading equipment—it’s a strategic investment in your business’s efficiency, safety, and scalability. With customizable designs, industry-leading certifications, and performance that meets the demands of modern manufacturing, it’s the ideal solution for businesses looking to reduce labor costs, enhance safety, and shorten production cycles. Starting at $20,200, it offers exceptional value for companies of all sizes—from small workshops to large-scale manufacturing facilities.

Elevate your industrial automation game with Herochu. Contact our team today to learn how we can tailor the Servo Swing Arm Handling Manipulator to your workshop’s unique needs.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Fiber Laser Automation Systems

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Advanced Sheet Metal Palletizing Robot for Efficient Automation Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Roll Out Cantilever Pipe Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Laser Loading and Unloading Systems Suction Crane Vacuum Lifter for Sheet Metal

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Pneumatic Cantilever Manipulator Vacuum Lifter Crane

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Automatic Pipe Storage Racks Automated Profile Storage Warehouse Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Cantilever Pipe Storage Rack

Read moreRated 0 out of 5