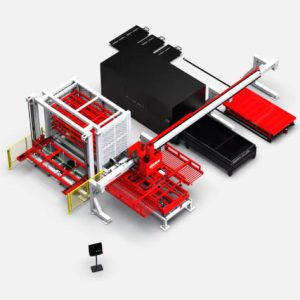

Herochu Fully Automatic Robot Precision Metal Stacking Manipulator

Revolutionizing Sheet Metal Automation with Unmatched Precision & Flexibility

Why Choose Herochu’s Palletizing Solution?

As industrial automation reshapes manufacturing paradigms, Herochu introduces the next-generation Fully Automatic Robot Precision Metal Stacking Manipulator – engineered to transform plate handling workflows. Certified under CE, UE, and ISO 9001 standards, this three-axis robotic system delivers ±0.5mm positioning accuracy and 150kg payload capacity, optimizing efficiency across laser cutting, warehousing, and material handling operations.

Core Features Driving Industrial Efficiency

- Smart Adaptability

- Customizable workspace (3000mm–48000mm) to fit workshop layouts

- Seamless integration with manual sheet libraries and multi-station loading

- Rapid product structure adjustments for flexible production scaling

- Precision Engineering

- ±3mm repeatability ensures consistent stacking quality

- 25m/min high-speed operation without compromising accuracy

- Handles sheet thickness from 0.5mm to 4mm with uniform grip stability

- Operational Excellence

- 700kg compact design maximizes floor space utilization

- Standardized automated splitting system reduces downtime

- Low-maintenance structure with intuitive operator controls

Transforming Sheet Metal Workflows

From Manual Labor to Automated Precision

Traditional plate stacking is labor-intensive, error-prone, and hazardous. Herochu’s solution:

- Eliminates manual handling of radioactive/toxic materials

- Reduces labor intensity by 60% in classification/transport tasks

- Boosts throughput with 24/7 unmanned operation

Industry-Specific Applications

- Laser Cutting: High-speed loading/unloading synchronization

- Warehousing: Accelerates sheet throughput with robotic sorting

- Automotive/Construction: Handles diverse metal profiles seamlessly

Technical Specifications

| Parameter | Specification |

|---|---|

| Axes | 3-axis |

| Positioning Accuracy | ±0.5mm |

| Repeatability | ±3mm |

| Max Speed | 25m/min |

| Payload | ≤150kg |

| Voltage | 220V, 50Hz/60Hz |

| Air Supply Pressure | 0.55MPa |

Certified Reliability

Backed by ISO 9001, CE, and UE certifications, Herochu’s robotic palletizer ensures:

- Operational safety in harsh environments

- Long-term durability with minimal maintenance

- ROI acceleration through cost reduction (starting at $20,200)

Your Path to Automation

Partner with Herochu to:

- Reduce cycle times by automating repetitive tasks

- Scale production with modular robotic stations

- Future-proof your workshop with upgradeable tech

Contact our automation experts today to customize your sheet metal stacking solution.