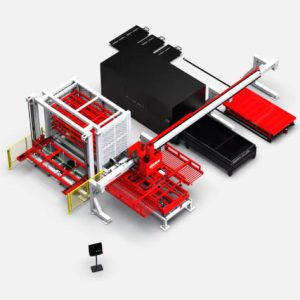

Herochu Factory Custom Cutting Machine: Automatic Loading, Unloading, Handling and Palletizing Solution

Bring sheet-metal automation into your workshop without compromise. The Herochu Factory Custom Cutting Machine integrates laser-grade cutting precision with fully automatic loading, unloading, handling and palletizing in one compact footprint. Built around a three-axis linear robot, the system is engineered from the ground up to match your production layout, material flow and budget, starting at USD 20,200. CE, UE and ISO 9001 certifications guarantee that every unit meets global safety, electrical and quality-management standards, giving procurement teams the confidence to deploy the machine in single-shift job shops or 24/7 mass-production lines.

Efficiency that scales with your order book

Traditional sheet-metal handling requires forklifts, overhead cranes and multiple operators to stage, cut and stack blanks. Herochu eliminates these bottlenecks by synchronising the robot with your existing laser or plasma cutting centre. Raw sheets are lifted from the automated splitter or manual sheet library, conveyed to the cutting table, and—once processed—picked up again for precise palletizing. The entire cycle runs at up to 25 m/min, turning idle laser time into productive throughput. Users report average cycle-time reductions of 35 % within the first month, translating directly into shorter lead times and higher revenue per shift.

Linear robot architecture for reliability

Unlike six-axis articulated arms that demand large safety zones and complex programming, the Herochu unit employs a three-axis gantry design. The X-beam travels up to 48 m to cover multiple cutting stations, while the Y- and Z-axes deliver ±0.5 mm positioning accuracy and ±3 mm repeatability. The result is a rigid structure with fewer wear points, lower maintenance cost and straightforward operator training. Should your workshop expand, additional X-rail sections can be bolted on without replacing the entire robot—future-proofing your capital investment.

Payload and thickness versatility

The standard vacuum gripper handles single sheets from 0.5 mm to 4 mm thickness and up to 150 kg in total load. An optional magnetic or mechanical gripper extends the range to perforated or oily blanks without manual intervention. Quick-change tooling allows the same robot to serve up to three cutting machines in sequence, optimising asset utilisation in mixed-product environments.

Plug-and-play integration

Electrical integration is equally simple. The control cabinet accepts single-phase 220 V, 50/60 Hz supply and requires only 0.55 MPa shop air. Ethernet and digital I/O ports connect directly to most CNC laser controllers via standard protocols, eliminating proprietary black boxes. Onboard recipe storage supports 255 part programs; a barcode scanner can call up the correct sequence automatically when pallets arrive from upstream shears or coil lines.

Safety and ergonomics

Laser-class light curtains, Category 3 safety relays and perimeter fencing come pre-wired to reduce site-installation time. The robot replaces operators in lifting, turning and stacking tasks, cutting injury-related downtime and workers’ compensation claims. In environments where blanks carry sharp edges, oil residue or chemical coatings, the Herochu solution keeps personnel clear of hazardous zones while maintaining full traceability through RFID pallet tags.

Customisation at every level

Herochu engineers work directly with your production, maintenance and HSE teams to adapt the system to existing aisle widths, ceiling heights and material sizes. Options include extended Z-stroke for tall stacking bins, side-mounted sheet libraries for high-volume runs, and automatic scrap conveyors that discharge skeletons directly into recycling hoppers. Colour, guarding style and HMI language are all configurable, ensuring the machine blends seamlessly into your corporate identity.

Service and support worldwide

Every unit ships with a two-year warranty on mechanical components and lifetime remote diagnostics access. Regional service hubs stock critical spares—drive belts, vacuum cups, proximity sensors—minimising mean time to repair. Training packages range from one-day operator certification to week-long maintenance boot camps, delivered on-site or through the Herochu Academy portal.

Return on investment you can measure

A mid-size fabricator producing 300 nests per week typically spends 14 operator-hours per shift on loading, sorting and stacking. At an average loaded labour rate of USD 25 per hour, the annual cost exceeds USD 91,000. The Herochu system pays for itself in less than nine months while freeing skilled technicians for higher-value programming and quality tasks. Additional savings accrue from reduced forklift traffic, lower sheet damage and the ability to run lights-out shifts during peak demand.

Take the next step toward unmanned productivity

Whether you are upgrading an existing laser cell or planning a green-field smart factory, the Herochu Factory Custom Cutting Machine delivers factory-grade automation without enterprise-grade complexity. Request a customised layout drawing, cycle-time analysis and ROI calculation today, and discover how automatic loading, unloading, handling and palletizing can elevate your sheet-metal operations from heavy labour to high-margin precision manufacturing.