Fiber Laser Automation | Automatic Loading And Unloading

The core of the Herochu automation system is its relentless focus on speed, precision, and autonomous operation. The system is capable of a remarkably fast continuous loading cycle, with feeding times as short as 110 seconds, ensuring your high-power laser source spends its time cutting, not waiting. A sophisticated height detection system continuously monitors the finished material pile in real-time. Once a pallet is full, the system issues an intelligent alert, prompting for part removal without interrupting the ongoing cutting process elsewhere in the system.

|

Specification

|

3015/4015/4020/6015/6020/6025mm

|

|

Number of floor

|

8-13

|

|

Load per layer

|

3T/5T

|

|

Mode of movement

|

Linear guide rail + chain

|

|

Transmission mode

|

Chain drive

|

|

Vertical lifting Speed

|

9m/min

|

|

Inlet and outlet Speed

|

12m/min

|

|

Plate Support

|

optional selection

|

Herochu Fiber Laser Automation: Unattended Precision for the Modern Fabrication Floor

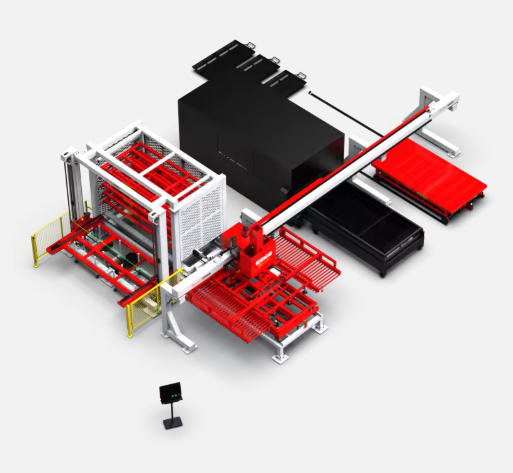

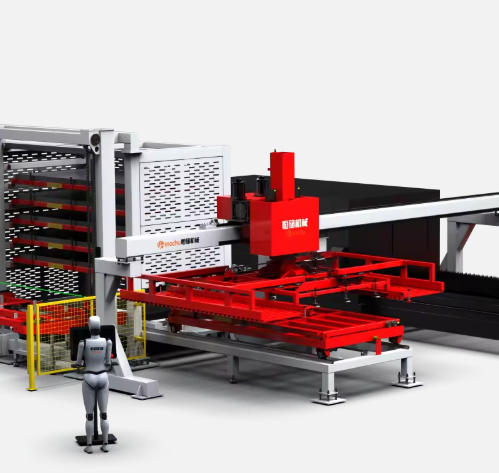

In the competitive landscape of modern metal fabrication, achieving peak efficiency requires more than just a powerful laser cutter; it demands a seamlessly integrated production cell. Manual loading, unloading, and material handling introduce significant bottlenecks, consuming valuable labor hours and limiting your machine’s true productive potential. Herochu redefines manufacturing workflow with our advanced Fiber Laser Automation Systems, featuring fully integrated Automatic Loading and Unloading paired with intelligent warehousing. This isn’t just an equipment upgrade—it’s a strategic transformation towards a lights-out manufacturing capability, engineered to maximize throughput, minimize operational costs, and deliver a rapid return on investment.

Our Automatic Loading and Unloading Laser Cutting Machine with Integrated Warehousing System represents the pinnacle of hands-off production. Designed as a complete turnkey solution, this system is meticulously crafted to operate continuously with minimal human intervention. By automating the entire material flow—from raw sheet storage through precision cutting to finished part segregation—Herochu eliminates the delays and inconsistencies of manual handling. The result is a dramatic increase in overall equipment effectiveness (OEE), allowing your business to accept more orders, meet tighter deadlines, and improve bottom-line profitability. This system is the definitive solution for workshops aiming to scale their operations and gain a formidable competitive edge.

Unmatched Operational Efficiency and Intelligent Design

The core of the Herochu automation system is its relentless focus on speed, precision, and autonomous operation. The system is capable of a remarkably fast continuous loading cycle, with feeding times as short as 110 seconds, ensuring your high-power laser source spends its time cutting, not waiting. A sophisticated height detection system continuously monitors the finished material pile in real-time. Once a pallet is full, the system issues an intelligent alert, prompting for part removal without interrupting the ongoing cutting process elsewhere in the system.

This high level of automation integration and dynamic performance makes the Herochu system incredibly versatile. It effortlessly processes a vast array of metallic materials, including mild steel, stainless steel, aluminum, and copper, across a wide range of thicknesses. Its application is critical across numerous industries such as automotive component manufacturing, industrial machinery production, electrical enclosure fabrication, elevator manufacturing, and commercial kitchen equipment production. By providing a consistent, unattended workflow, it liberates skilled operators to oversee multiple cells or focus on value-added tasks like quality inspection and programming, further optimizing your shop’s output.

Tangible Advantages That Drive Your Business Forward

Investing in Herochu Fiber Laser Automation translates into direct, measurable benefits for your operation:

-

Exceptional Processing Speed: The integrated automation system minimizes non-cutting time. The mechanical components are engineered for rapid movement, achieving a continuous loading time of just 110 seconds. Furthermore, the optimized motion control and cutting parameters can increase cutting speeds by at least 10% on materials like 10mm stainless steel compared to standard manual operations, effectively doubling your throughput while maintaining superior cut quality.

-

Complete Production Autonomy: Built upon a robust laser cutting platform, the automatic loading and unloading system facilitates complete batch processing without the need for manual intervention from start to finish. This seamless automation drastically reduces labor dependencies, mitigates risks associated with operator fatigue, and enables profitable overnight and weekend production runs.

-

Environmental and Material Efficiency: The system is designed with sustainability and cost-saving in mind. Advanced nesting software ensures the optimal utilization of raw sheet material, significantly reducing waste and often achieving near “0” tailings. The large, fully enclosed housing serves a dual purpose: it provides maximum protection against laser radiation for a safer workshop environment and prevents mechanical damage to the delicate internal components, ensuring long-term reliability and stability.

-

Superior Cost-Effectiveness: The economic advantages are compelling. The automation system itself offers a low cost of ownership relative to the productivity gains it unlocks. Notably, the cutting process is highly efficient; depending on the material and application, the operational cost can be as low as 10% compared to traditional nitrogen-cutting methods. This drastic reduction in gas consumption and increased output creates substantial economic value, ensuring a quick payback period.

Certified Quality and Tailored Integration

Herochu stands behind the quality and safety of every system we produce. Our manufacturing processes are certified under the ISO 9001 quality management system, and our equipment carries CE and UE certification, guaranteeing full compliance with stringent European safety and environmental directives. We understand that every workshop has unique spatial and production requirements. Therefore, our Fiber Laser Automation Systems are fully customizable. Starting at $20,200, we offer a scalable automation solution that can be tailored to your specific workflow, material types, and volume needs, ensuring a perfect fit for your facility.

Embrace the future of metal fabrication. Contact Herochu today to schedule a consultation and discover how our Automated Fiber Laser Cutting Systems can revolutionize your productivity, enhance your safety, and drive your profitability to new heights.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Advanced Sheet Metal Palletizing Robot for Efficient Automation Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Roll Out Cantilever Pipe Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Laser Loading and Unloading Systems Suction Crane Vacuum Lifter for Sheet Metal

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Pneumatic Cantilever Manipulator Vacuum Lifter Crane

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Automatic Pipe Storage Racks Automated Profile Storage Warehouse Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Cantilever Pipe Storage Rack

Read moreRated 0 out of 5