Herochu Sheet Metal Racks for Storage & Organization – Engineered Precision, Certified Confidence

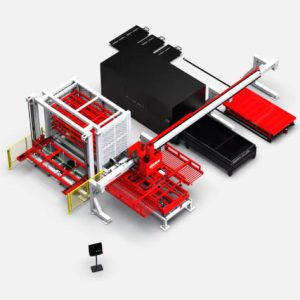

Transform the way you handle steel, aluminum, copper, and composite flat stock with Herochu’s roll-out sheet metal racks. From compact job-shops to high-throughput fabrication centers, our modular systems convert under-used vertical air into profitable floor space, giving every plate, off-cut, or blank a clearly defined, instantly accessible home. Starting at $5,199 and customizable to the last millimeter, each rack is CE, UE, and ISO 9001 certified, delivering global compliance alongside local practicality.

Standard models for immediate deployment

• HC-B3015-63 – 3 000 mm x 1 500 mm plates, six layers, 3 t per drawer

• HC-B4015-63 – 4 000 mm x 1 500 mm plates, six layers, 3 t per drawer

• HC-B4020-65 – 4 000 mm x 2 000 mm plates, six layers, 5 t per drawer

• HC-B6020-66 – 6 000 mm x 2 000 mm plates, six layers, 6 t per drawer

For facilities with non-standard ceilings, irregular crane spans, or mixed material inventories, our engineering team produces tailor-made widths, depths, and load ratings without extending lead times. Whether you need eight layers of thin-gauge aluminum or three reinforced tiers for 25 mm armor plate, the same precision cut, robot-welded frame guarantees deflection-free operation year after year.

Space multiplication that pays for itself

Each rack stands only 2 280 mm high yet exploits the full clear height of a typical workshop bay. Five active drawer levels plus a stationary top deck create six independent pick faces within a single footprint. When fully extended, drawers reveal 100 % of their surface, eliminating the dangerous lean-and-reach routine that slows production and strains backs. One technician operating a vacuum lifter, magnetic hoist, or lightweight crane can cycle through six tons of inventory in minutes, freeing forklifts for value-added tasks elsewhere.

Heavy-duty by design, not by accident

Side frames are fabricated from 6 mm laser-cut plate, continuously welded to 120 x 120 mm RHS uprights. Drawer chassis ride on sealed, hardened-steel linear bearings rated for 50 000 cycles at full load. A patented lock-in/lock-out mechanism ensures the drawer remains positively restrained during loading, yet releases instantly for smooth extension. The clearance height of 355 mm beneath the first tier keeps stock clear of floor contaminants, while a 60 mm replaceable depth pad protects edges from accidental impact.

Safety that meets tomorrow’s standards today

Every weld is ultrasonic-tested, every frame is proof-loaded to 1.5 times rated capacity, and every unit ships with an integrated maintenance log tied to its unique serial number. Yellow powder-coat finish provides high visibility and chemical resistance, and optional overhead mesh or polycarbonate guards guard against falling debris when racks are installed beneath elevated walkways or crane runways. The entire system complies with CE machinery directive 2006/42/EC, UE structural steel code EN 1993, and ISO 9001 quality management procedures.

Seamless integration with existing workflows

Roll-out racks position sheet edges at an ergonomic 890 mm above floor level—perfectly aligned with laser shuttle tables, shear in-feeds, or press-brake back gauges. When placed back-to-back, two racks create a 4 000 mm wide service aisle that accepts standard overhead bridge cranes. Forklift pockets integrated into the base allow repositioning without disassembly, and adjustable floor anchors accommodate both epoxy-sealed and untreated concrete slabs.

Customizable from the first sketch to final commissioning

If our four standard footprints do not fit, we redraw. Need 5 500 mm x 1 800 mm tiers for marine-grade stainless? We re-profile the frame and upgrade bearings to 8 t capacity. Working in a low-ceiling mezzanine? We reduce upright height to 1 900 mm and add extra reinforcing ribs. Prefer drawers to open from the long side rather than the short? We mirror the entire chassis. Each customization is quoted within 24 hours and backed by the same five-year structural warranty.

Return on investment you can measure

A typical fabrication shop storing 150 t of sheet stock on traditional floor blocks sacrifices roughly 210 m² of floor space. Reclaiming that real estate with Herochu vertical racks often cuts the footprint to 42 m²—an 80 % reduction that translates into two additional press brakes, three more welding stations, or simply safer, faster traffic flow. At current industrial lease rates, the payback period averages fourteen months, excluding productivity gains from reduced search time and material damage.

Support that continues after the invoice

Our technical team provides on-site installation supervision, operator training, and annual load-testing services worldwide. Replacement bearings, edge protectors, and powder-coat touch-up pens are stocked regionally for next-day delivery, ensuring your Herochu rack performs like new long after the competition’s painted angle-iron shelves have twisted out of alignment.

Choose Herochu Sheet Metal Racks for Storage & Organization and give every sheet a place, every operator a clear path, and every project a head start. Contact our application engineers today for a footprint analysis, custom quotation, or to schedule a virtual walk-through of your upgraded workspace.