Sheet metal Vacuum Lifters

At the core of the Herochu Vacuum Lifter is a robust, horizontally fixed frame with a standard length of 2000mm, though customizable to 2500mm to suit specific needs. Its most notable design feature is its remarkably lowered profile, standing at just 415mm tall. This compact geometry is a critical advantage, allowing the lifter to operate effortlessly in environments with low ceiling heights or where overhead obstacles are present, a common scenario in many manufacturing plants.

| item | value |

| Vertical Travel(mm) | 1850mm |

| Horizonal Travel(mm) | 3000mm |

| Warranty | 1 Year |

| Place of Origin | China |

| Weight | 500 |

| Dimension(L*W*H) | 3800×1700*1700mm |

| Condition | New |

| Brand Name | Herochu |

| Power | 600w |

Herochu Sheet Metal Vacuum Lifters: Precision Engineered for Safe and Efficient Handling

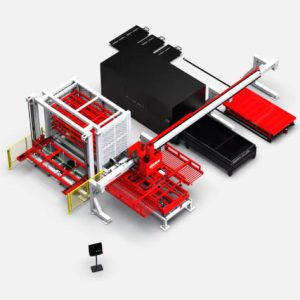

In the demanding world of metal fabrication and processing, the handling of sheet materials—from delicate aluminum and stainless steel to heavy-grade metals—presents a significant operational challenge. Manual lifting is not only inefficient and labor-intensive but also poses substantial risks to both operator safety and material integrity. Scratches, bends, and drops are constant, costly threats. The Herochu Sheet Metal Vacuum Lifter is a professionally engineered solution designed to eliminate these challenges entirely. This compressed air-powered system introduces a new standard of precision, safety, and operational efficiency for workshops handling sheet metal, starting at an accessible investment of $3,698.

Certified to CE, UE, and ISO 9001 standards, the Herochu Vacuum Lifter is more than a simple tool; it is a sophisticated material handling partner. It transforms a two or three-person lifting task into a seamless, one-person operation, drastically reducing labor costs and minimizing the potential for workplace injuries. By utilizing the power of vacuum, it ensures a secure, damage-free grip on sheets, preserving their pristine surface condition from the cutting machine through to the final destination. This technology is indispensable for any operation focused on quality, throughput, and workplace safety.

Superior Engineering for Unmatched Performance and Adaptability

At the core of the Herochu Vacuum Lifter is a robust, horizontally fixed frame with a standard length of 2000mm, though customizable to 2500mm to suit specific needs. Its most notable design feature is its remarkably lowered profile, standing at just 415mm tall. This compact geometry is a critical advantage, allowing the lifter to operate effortlessly in environments with low ceiling heights or where overhead obstacles are present, a common scenario in many manufacturing plants.

Mounted on this pressurized main crossbeam, which acts as an integrated vacuum reservoir for consistent performance, are four adjustable arms fitted with eight vulcanized oil-resistant rubber suction pads. A key engineering highlight is the spring system integrated into each suction plate. This intelligent feature actively compensates for the natural bending or slight warping often found in large sheets, ensuring perfect load balancing and a secure hold throughout the entire lifting and moving process. This design is so effective it allows for the safe movement of even the thinnest gauge materials without any risk of bending or damage.

Operational Excellence and Intuitive Control

The system is powered by standard workshop compressed air, making it an ideal and readily integrated partner for jib cranes and other lifting equipment already connected to an air compressor. This pneumatic supply eliminates the need for complex electrical hookups near lifting operations, enhancing overall safety. The lifter specializes in smooth horizontal movement, enabling operators to effortlessly transport sheets from a stack to a machine bed—such as a punch press, laser cutter, or bending brake—with pinpoint accuracy.

Operation is straightforward and intuitive. The operator simply positions the lifter over the sheet, lowers it until the pads make contact, and activates the sliding valve to initiate suction. A large, color-scaled vacuum gauge provides a constant, clear visual confirmation of the secure vacuum level. To release the load, a single action of the sliding valve safely breaks the seal. Shut-off taps on individual arms provide further control, allowing operators to isolate sections when handling smaller or irregularly sized sheets up to 3000x1500mm.

Comprehensive Safety Systems for Complete Peace of Mind

Herochu prioritizes operator and load safety above all else. The vacuum lifter is equipped with a multi-layered safety guarantee system that functions automatically to prevent accidents. An audiovisual alarm system provides immediate warning to the operator in the event of a detected pressure drop or potential vacuum failure. The integrated non-return valve is a critical failsafe; it instantly locks in the existing vacuum should the power supply be interrupted, preventing a catastrophic load drop.

Furthermore, a built-in vacuum filter protects the internal pneumatic circuit from harmful dust, debris, and condensation, ensuring the long-term reliability and performance of the system. These features combine to create a handling environment where operators can work with confidence, knowing that both their safety and the security of valuable materials are fundamentally assured.

Specifications and Deployment

The Herochu Sheet Metal Vacuum Lifter is built to perform in the most intensive industrial settings. With a maximum capacity of 600 kg, it is capable of handling the vast majority of sheet metal tasks with ease.

Key Specifications:

-

Max Capacity: 600 kg

-

Liftable Sheet Format: 3000×1500 mm

-

Number of Suction Pads: 8 (adjustable)

-

Power Supply: Compressed Air

-

Vertical Travel: 1850 mm

-

Horizontal Travel: 3000 mm

-

Frame Height: 415 mm (Lowered Profile)

-

Overall Dimensions (LxWxH): 3800x1700x1700 mm

-

Standard Features: Adjustable suction pads, Audiovisual alarm, Oil-resistant rubber pads, Spring support system, Shut-off taps, Non-return valve, Vacuum filter, Vacuum gauge.

-

Warranty: 1 Year

-

Packaging: Secure, robust packaging ensuring safe delivery worldwide.

Ideal for industries including metal fabrication, machinery repair, manufacturing plants, and construction, the Herochu Vacuum Lifter is a transformative investment. It enhances productivity by accelerating handling cycles, reduces costs associated with damage and injury, and empowers a workforce with advanced, easy-to-use technology.

To explore how this customizable vacuum lifting solution can be integrated into your workshop’s workflow, contact our technical team today for a detailed consultation.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Material Handling Equipment

Handling of plates and sheets, vacuum lifting

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Sheet Metal Vacuum Lifting Device

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5