Metal Sheet Handling Equipment

The Herochu Metal Sheet Handling Equipment is powered by compressed air—a choice that aligns with the demands of industrial environments. Pneumatic power is ideal for use with jib cranes or other lifting means connected to a workshop compressor, eliminating the need for complex electrical setups or battery replacements. The system’s 600w power output ensures consistent suction force, even when handling maximum loads of 600kg—more than enough for heavy steel sheets or stacked aluminum panels.

Pneumatic Manipulator

This machine has the characteristics of light structure, easy disassembly and assembly, and wide application. High efficiency, short handling cycle, and can be stopped at any position, making the handling process easy, fast and continuous. High safety performance, with air cut-off protection and anti-collision devices.

Specification

|

Model

|

HC-RP3015-300

|

HC-RP3015-500

|

HC-RP3015-1000

|

HC-RP4020-300

|

HC-RP4020-500

|

|

Thickness of feeding plate

|

8mm

|

12mm

|

20mm

|

8mm

|

12mm

|

|

Maximum feeding width

|

3000*1250mm

|

4000*1250mm

|

|||

|

Minimum feeding width

|

1250*1250mm

|

1250*1250mm

|

|||

|

Maximum plate weight

|

300kg

|

500kg

|

1000kg

|

300kg

|

500kg

|

|

Number of suction cups

|

8

|

8

|

10

|

8

|

8

|

|

Suction cup diameter

|

200

|

200

|

250

|

200

|

200

|

|

Power mode

|

Pneumatic/Electric

|

||||

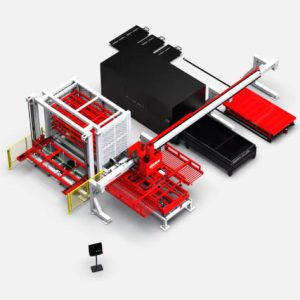

Herochu Metal Sheet Handling Equipment: Industrial-Grade Vacuum Lifter for Streamlined Sheet Metal Operations

For workshops, manufacturing plants, and fabrication facilities that rely on efficient, damage-free sheet metal handling, the Herochu Metal Sheet Handling Equipment emerges as a game-changing solution. Designed specifically to tackle the unique challenges of loading and unloading sheet metal, stainless steel, steel, aluminum, and non-ferrous materials from cutting machines, this vacuum-powered system eliminates the inefficiencies of manual labor and the risks of material damage associated with generic lifting tools. Backed by CE, UE, and ISO 9001 certifications, it meets global quality and safety standards—ensuring consistent performance in even the most demanding industrial settings. Best of all, it’s fully customizable to fit your workshop’s layout and workflow, with pricing starting at just $3,698.

Engineered for Versatility: Adaptable to Any Sheet Metal Size

One of the standout strengths of the Herochu Metal Sheet Handling Equipment is its ability to adapt to diverse sheet metal dimensions—making it a flexible asset for facilities handling varying workloads. The system features 8 suction pads mounted on 4 adjustable arms, which slide along a horizontally fixed main crossbeam (available in a standard 2500mm length) to match the size of your sheet metal. Whether you’re working with small panels or full-size sheets up to 3000x1500mm (the maximum liftable format), you can reposition the suction pads quickly to ensure secure, even gripping.

The suction pads themselves are crafted from vulcanized oil-resistant rubber—a durable material that stands up to frequent use and industrial fluids, while also preventing scratches or dents on delicate sheet surfaces. Each pad is equipped with a spring system, a critical design element that compensates for the natural bending of thin sheets. This ensures proper load balancing throughout the entire handling process, even when moving the thinnest metal sheets—effectively eliminating the risk of load warping or damage that can occur with rigid lifting tools.

Compact Design for Low-Ceiling Environments

Many industrial facilities face space constraints, particularly when it comes to ceiling height—a challenge that the Herochu Metal Sheet Handling Equipment addresses head-on. Its unique lowered and compact frame structure boasts a reduced height of only 415mm, allowing it to operate seamlessly in areas with low ceilings or overhead obstacles. This design doesn’t compromise on performance, though: the main crossbeam (500mm long in its core configuration) is pressurized and functions as a built-in vacuum reservoir, optimizing both the weight and dimensions of the system. At just 500kg total weight and with overall dimensions of 3800x1700x1700mm, the equipment fits easily into most workshop layouts without requiring extensive reconfiguration.

The horizontal movement capability of the system further enhances its usability, enabling precise positioning of sheet metal onto cutting machines, bending presses, or storage racks. This precision reduces the time spent adjusting materials manually, cutting down on production bottlenecks and improving overall workflow efficiency.

Pneumatic Power: Reliable Performance for Industrial Use

The Herochu Metal Sheet Handling Equipment is powered by compressed air—a choice that aligns with the demands of industrial environments. Pneumatic power is ideal for use with jib cranes or other lifting means connected to a workshop compressor, eliminating the need for complex electrical setups or battery replacements. The system’s 600w power output ensures consistent suction force, even when handling maximum loads of 600kg—more than enough for heavy steel sheets or stacked aluminum panels.

A sliding valve controls both suction and release, making operation intuitive: with a simple adjustment, operators can engage the vacuum to grip sheets or release it to set materials down precisely. The pneumatic design also minimizes maintenance needs, as it has fewer moving parts than electric systems and is less susceptible to wear from dust or debris common in fabrication shops.

Safety First: Protecting Operators and Materials

Safety is embedded in every component of the Herochu Metal Sheet Handling Equipment. The system features a comprehensive safety package to prevent accidents and material loss:

- Audiovisual Alarm System: Warns operators of potential issues (such as low vacuum pressure) in real time, allowing for immediate action before problems escalate.

- Colored Scaled Vacuum Gauge: Provides clear visibility of vacuum levels in the circuit when suction is engaged, so operators can confirm a secure grip before moving loads.

- Non-Return Valve: Prevents vacuum loss in the event of a temporary supply interruption, keeping sheets securely held until power is restored.

- Vacuum Filter: Protects the internal circuit from dust, condensation, and debris—ensuring consistent performance and extending the life of the system.

These features work together to create a safe working environment: operators can handle heavy sheets with confidence, knowing the equipment will alert them to risks, and sensitive materials remain protected from drops or damage.

Technical Specifications: Built for Industrial Durability

Every detail of the Herochu Metal Sheet Handling Equipment is engineered for durability and performance. Key technical attributes include:

- Vertical Travel: 1850mm (enough to reach most machine beds and storage shelves).

- Horizontal Travel: 3000mm (enabling wide coverage across workshop floors).

- Max Capacity: 600kg (handles heavy-duty loads with ease).

- Number of Suction Pads: 8 (ensures even weight distribution).

- Frame Material: Industrial-grade steel (resists corrosion and impact in busy shops).

- Power Source: Compressed air (compatible with standard workshop compressors).

- Condition: Brand-new (backed by Herochu’s rigorous quality control).

The equipment is shipped as a single item, with each package measuring 3000x100x300cm and weighing 20kg—making delivery and installation straightforward. Herochu’s team provides guidance to ensure the system is set up correctly, so you can start using it quickly.

1-Year Warranty and All-Round Support

Herochu stands behind the quality of its Metal Sheet Handling Equipment with a 1-year warranty, covering parts and labor for any defects or performance issues. Beyond the warranty, our team offers comprehensive support: from helping you customize the system to fit your specific workshop layout, to providing operator training and responsive maintenance assistance. Whether you need help adjusting the suction pad positions for a new sheet size or troubleshooting a pneumatic connection, we’re dedicated to keeping your operations running smoothly.

Why Choose Herochu’s Metal Sheet Handling Equipment?

In a market saturated with one-size-fits-all lifting tools, the Herochu Metal Sheet Handling Equipment stands out for its:

- Industry-Specific Design: Built exclusively for sheet metal handling, addressing the unique challenges of thin, large, or heavy materials.

- Customization: Tailored to your workshop’s space and workflow, so it integrates seamlessly rather than disrupting operations.

- Certified Quality: CE, UE, and ISO 9001 certifications ensure compliance with global standards, giving you confidence in its safety and performance.

- Affordability: Starting at $3,698, it delivers industrial-grade reliability without the premium price tag of competitors.

- Space Efficiency: The compact, low-height design works in tight or low-ceiling environments where other equipment can’t.

Whether you’re a small fabrication shop looking to reduce manual labor or a large manufacturing plant aiming to streamline production, the Herochu Metal Sheet Handling Equipment is built to grow with your business. It turns sheet metal handling from a labor-intensive, high-risk task into a fast, safe, and efficient step—saving you time, reducing waste, and protecting your team. Invest in equipment that’s as dedicated to your success as you are: choose Herochu.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Material Handling Equipment

Handling of plates and sheets, vacuum lifting

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Sheet Metal Vacuum Lifting Device

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5