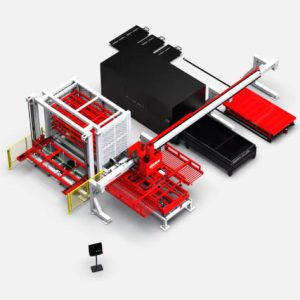

Herochu Vacuum Lifters for Sheet Metal: Precision Handling for Industrial Efficiency

Engineered for Heavy-Duty Sheet Materials

Sheet metal is a cornerstone material in manufacturing, construction, and fabrication, yet its handling presents significant challenges—weight, smooth surfaces, sharp edges, and varied forms (flat sheets or coiled strips). Herochu’s vacuum lifters are purpose-built to address these challenges, offering a safer, more efficient alternative to manual handling or traditional lifting equipment. With CE, UE, and ISO 9001 certifications, these lifters are designed for reliability in demanding industrial environments.

How Vacuum Lifters Revolutionize Sheet Metal Handling

Vacuum lifters utilize powerful suction technology to secure loads without straps or hooks. Herochu’s models feature:

- 8 adjustable suction pads with vulcanized rubber surfaces for optimal grip

- Spring-loaded balancing systems to prevent bending during transport

- Compact 415mm lowered frame for operation in low-ceiling spaces

- Curved suction cup options for handling coiled materials

This technology eliminates manual securing, reducing downtime and improving workplace safety.

Key Features & Specifications

| Attribute | Specification |

|---|---|

| Vertical Travel | 1850mm |

| Horizontal Travel | 3000mm |

| Max. Capacity | 600kg |

| Power Supply | 600W compressed air |

| Dimensions (L×W×H) | 3800×1700×1700mm |

| Weight | 500kg |

| Warranty | 1-year coverage |

Safety & Operational Excellence

Herochu lifters include:

- Audiovisual alarms for real-time vacuum monitoring

- Non-return valves to prevent dust/condensation damage

- Sliding valve mechanisms for intuitive control

Global Reliability, Custom Solutions

Manufactured in China, Herochu units are shipped worldwide with robust packaging. Starting at $3,698, these lifters are customizable to workshop needs, supporting jib cranes and compressor systems for seamless integration.

Why Choose Herochu?

- Cost-Effective: Factory-direct pricing with modular upgrade options

- Maintenance-Free: Oil-resistant components minimize downtime

- Future-Proof: Designed for scalability as operational needs evolve

For industries prioritizing precision, safety, and productivity, Herochu’s vacuum lifters are the definitive solution for sheet material handling. Contact us today for tailored configurations.