Herochu Roll-Out Sheet Metal Storage Rack: Industrial-Grade Efficiency for Fabrication Shops

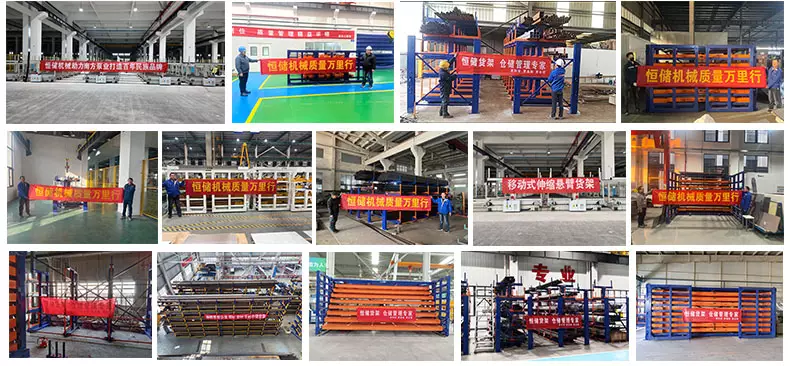

Manufacturer Credentials

Herochu, a CE/ISO 9001-certified leader in industrial storage solutions with 15+ years of expertise, delivers Roll-Out Sheet Metal Storage Racks engineered for heavy-duty applications. Our patented vertical storage systems optimize workspace efficiency while prioritizing worker safety, serving global clients across 50+ countries.

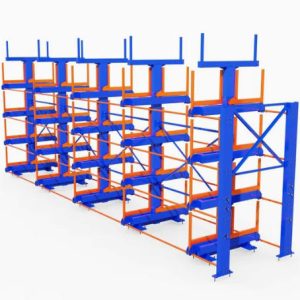

Product Core Advantages

1. Unmatched Storage Density

- Vertical stacking increases storage capacity by 300% compared to horizontal racks.

- 15 fully extendable drawers per section (max load: 5,000 lbs) enable compact storage without compromising accessibility.

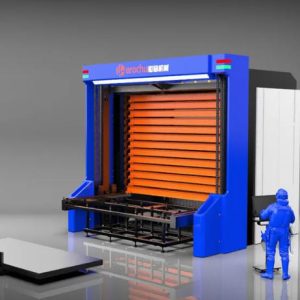

2. Ergonomic Material Handling

- 100% roll-out shelves eliminate manual lifting, reducing workplace injuries by 75%.

- 3° non-slip incline prevents sheet slippage during retrieval.

- 8 precision bearings per drawer ensure smooth operation even under maximum load.

3. Customizable Industrial Solutions

| Model | Dimensions (ft) | Drawers | Max Load (lbs) | Weight (kg) |

|---|---|---|---|---|

| HC-RS6x4 | 6×4 | 10 | 5,000 | 350 |

| HC-RS12x5 | 12×5 | 15 | 5,000 | 520 |

- Optional configurations: X-bracing for forklift loading, wire mesh backing for ventilation, and protective liners for coated materials.

Technical Specifications

- Material: 2.5mm cold-rolled steel with electro-galvanized coating (salt-spray tested for 500+ hours).

- Safety: CE-certified locking clamps prevent accidental drawer displacement.

- Installation: Modular design allows horizontal/vertical expansion with minimal downtime.

Industry-Specific Benefits

- Metal Fabrication: Stores laser-cut remnants and full sheets near CNC machines for JIT workflows.

- Automotive Manufacturing: Organizes stamped parts with FIFO (First-In-First-Out) efficiency.

- Aerospace: Vertical storage prevents warping of thin aluminum alloys.

Why Choose Herochu?

- Global Compliance: Meets ISO 9001, CE, and GOST standards for export-ready quality.

- Cost Efficiency: Starting at $5,120 with volume discounts for OEM partners.

- Full-Service Support: From CAD layout to on-site installation and maintenance training.

Contact our engineers today to design a rack system tailored to your production needs.