Automatic plate storage system

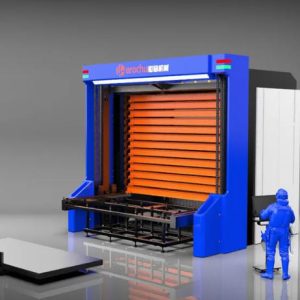

The Herochu Automatic Plate Storage System is architected around a foundation of robust mechanical engineering and sophisticated digital control. It is designed for the centralized storage of metal plates across a diverse range of grades, thicknesses, and dimensions. Upon intake, the system performs automatic weight detection, seamlessly integrating this data into its inventory management system. The processes of warehousing and retrieval are entirely automated, engineered to function without human intervention, thereby eliminating the errors, delays, and risks associated with manual handling.

Herochu Automatic Plate Storage System: Engineering the Future of Unmanned Industrial Warehousing

Industrial manufacturing continues to evolve at a relentless pace, demanding unprecedented levels of efficiency, precision, and integration. Within this complex ecosystem, the storage and handling of raw sheet metal and processed components remain a critical bottleneck for countless operations. Traditional methodologies, reliant upon manual labor, extensive forklift traffic, and disorganized storage racks, are inherently inefficient. These outdated practices consume a prohibitive amount of valuable floor space, expose high-value materials to damage and degradation, and present significant safety hazards to personnel. Moreover, they create a formidable disconnect within increasingly automated production environments, stifling productivity and inflating operational costs.

Herochu, a manufacturer recognized internationally for its adherence to CE, UE, and ISO 9001 standards, provides a definitive engineering solution to these challenges. Our Automatic Plate Storage System represents a fundamental paradigm shift in material logistics, moving beyond simple storage to create a fully integrated, intelligent handling ecosystem. This system serves as the central nervous system for the modern smart factory, delivering unmatched control, security, and operational throughput. With a strategic entry point of $19,998, Herochu makes advanced industrial automation an accessible and transformative investment for businesses committed to optimizing their workflow and securing a durable competitive advantage in a demanding market.

Core Engineering Principles: Automated Intelligence in Action

The Herochu Automatic Plate Storage System is architected around a foundation of robust mechanical engineering and sophisticated digital control. It is designed for the centralized storage of metal plates across a diverse range of grades, thicknesses, and dimensions. Upon intake, the system performs automatic weight detection, seamlessly integrating this data into its inventory management system. The processes of warehousing and retrieval are entirely automated, engineered to function without human intervention, thereby eliminating the errors, delays, and risks associated with manual handling.

The mechanical operation is driven by a precision-engineered combination of linear guide rails and a chain drive transmission system. This configuration guarantees smooth, accurate, and exceptionally stable movement, even under maximum load conditions. Performance metrics are optimized for industrial applications, with a vertical lifting speed of 9 meters per minute and an inlet/outlet speed of 12 meters per minute. This careful calibration ensures a perfect balance between rapid cycle times and the absolute integrity of the materials being handled. Supreme command over this process is managed by an industrial-grade Programmable Logic Controller (PLC), which interfaces with an intuitive touch-screen human-machine interface (HMI). This control architecture achieves a state of classified visual management, granting operators a comprehensive, real-time overview of all inventory levels, precise material locations, and overall system status, thereby guaranteeing both peak operational efficiency and the highest standards of safety.

Transforming Remnant Management: From Chaos to Control

A particularly persistent challenge in metal fabrication is the efficient management of remnant sheets following cutting or punching operations. These useful parts are often difficult to store and are frequently managed in an ad-hoc and inefficient manner, leading to loss, damage, and underutilization. The Herochu system is equipped with an integrated management protocol that allows for the effortless registration and organized storage of these leftover sheets. This specialized functionality maintains workshop organization and ensures that valuable remnant material can be easily identified and reused at a later date, preventing obstruction and loss. This transforms what was once a logistical headache into a manageable and profitable asset, reducing material waste and improving overall job costing accuracy.

Seamless System Integration: The Cornerstone of the Unmanned Factory

The ultimate capability of the Herochu system is realized through its seamless integration into a complete, automated production cell. It functions as the central hub for material flow, synchronizing disparate machinery into a cohesive, unmanned operation.

The system can be effortlessly linked to existing conveyor systems and other material handling solutions, further streamlining the internal logistics of any workshop. Its true power is demonstrated in advanced integrations, such as a Sheet Storage System + Double Beam Rack Loading/Unloading Machine + Laser Cutting Machine combination. This configuration facilitates a fully unmanned cutting process:

-

The system automatically identifies and retrieves the required raw sheet from its designated location.

-

A Double Beam machine lifts the sheet and feeds it directly into the laser cutting machine.

-

Upon completion of cutting, the automated system unloads the machine bed, automatically separating finished products from the skeleton waste.

-

Finally, the finished products are transported and fed back into the storage system for secure keeping, completing a closed-loop process without any manual intervention.

This interoperability extends far beyond laser cutting. The system is designed for maximum flexibility and can interface with a vast array of automated production lines, including shear centers, automatic punching centers, robotic press brakes, rolling centers, welding production lines, and spraying lines. It acts as both a supplier of raw materials and a receiver of finished goods, forming the indispensable cornerstone of a truly unmanned factory environment. Furthermore, its capability to connect with enterprise Manufacturing Execution Systems (MES) allows for the seamless flow of real-time inventory data into broader production planning and enterprise resource planning (ERP) ecosystems, enabling truly data-driven decision-making at an organizational level.

Delivering Measurable Operational Advantages

The implementation of a Herochu Automatic Plate Storage System delivers a compelling and rapid return on investment across multiple key performance indicators:

-

Unprecedented Space Utilization and Flexibility: One of the system’s unique features is its ability to store sheets of various formats simultaneously. This offers a high degree of flexibility, as operations are not limited to a single standard size. By storing plates vertically in a compact footprint, the system drastically reduces the floor space required for inventory compared to traditional racking or floor stacking. This reclaimed space can be repurposed for additional production capacity or lead to reduced facility overheads.

-

Enhanced Safety and Reduced Infrastructure Wear: The deployment of our automated storage systems significantly reduces, and often eliminates, the need for internal forklift and overhead crane movements. Traditional methods require numerous manual operations and movements of heavy machinery, which are time-consuming and carry inherent risks. By minimizing these movements, the system fosters a safer working environment with a markedly lower risk of accidents and collateral material damage. It also reduces wear and tear on other material handling equipment.

-

Superior Material Quality and Asset Protection: Sheets are stored securely in a controlled, organized manner, protecting them from the scratches, dings, and environmental exposure that are commonplace in manual handling. This preservation of material integrity directly reduces scrap rates, improves the quality of finished products, and protects the company’s financial investment in raw materials.

-

Maximized Production Efficiency and Agile Management: The system provides instant, software-directed access to any specific sheet in the inventory within moments, utterly eliminating the time wasted searching for materials. This reliability and speed streamline the entire manufacturing process, reduce machine idle time, accelerate order fulfillment, and minimize labor costs associated with material handling. Management is simplified through intuitive software that provides instant visibility into stock levels and location history.

Technical Specifications and Customization

The Herochu system is engineered to meet your precise operational requirements. Standard plate support sizes include 3015, 4015, 4020, 6015, 6020, and 6025mm, with comprehensive customization available. Load capacity is robust at 3 to 5 tons per layer. Critically, the number of floors and the total number of storage units within the system are fully customizable, ensuring a perfect fit for current volume needs while providing built-in scalability for future business growth. Various plate support options are available to accommodate different material types and specific handling requirements.

A Partnership Built on Assurance and Quality

Every new Herochu development undergoes extensive testing within our own factory facilities, ensuring that every product delivered meets the highest possible quality standards before it reaches your workshop. Our philosophy is straightforward: we either execute correctly, or we do not proceed. We pride ourselves on collaborating closely with our customers to deliver tailor-made solutions that perfectly align with their unique needs and business processes. Furthermore, our dedicated service team is always ready to provide rapid and competent support, giving you the assurance that you can always depend on an optimally functioning storage system.

Conclusion: The Strategic Imperative for Modern Manufacturing

The Herochu Automatic Plate Storage System is more than a piece of equipment; it is a strategic capital investment that transforms a logistical cost center into a powerful hub of efficiency, quality, and data-driven automation. It is the definitive choice for forward-thinking manufacturers who refuse to let antiquated storage practices constrain their growth, compromise their safety, and erode their profitability.

Contact Herochu today to initiate a detailed consultation with our automation specialists. Provide our engineering team with your workshop parameters and production objectives, and we will develop a customized Automatic Plate Storage System designed to serve as the foundational engine for your unmanned factory, driving productivity and profitability for years to come.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Intelligent Sheet Metal Storage System

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Handling of plates and sheets, vacuum lifting

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Sheet Metal Vacuum Lifting Device

Read moreRated 0 out of 5