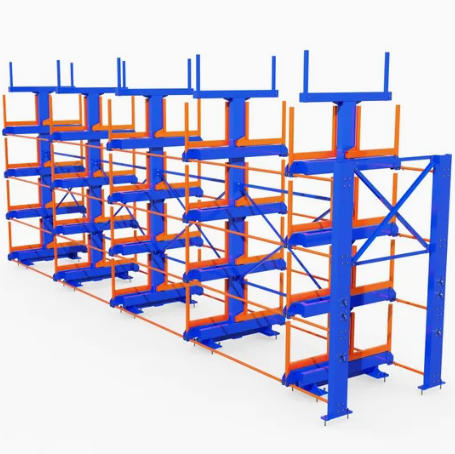

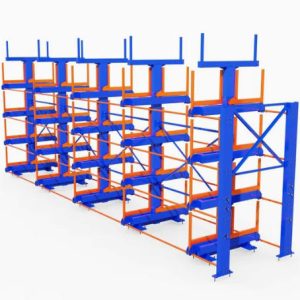

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Representing the next evolutionary step in warehouse optimization, the Herochu system is custom-built to your facility’s exact specifications, starting at $3,099. It is a capital investment that pays for itself through radical gains in space efficiency, workflow velocity, and operational safety. Every component, from the high-tensile steel to the precision-machined bearings, is manufactured under the most stringent international quality assurance protocols, bearing CE, UE, and ISO 9001 certification.

Herochu Telescopic Cantilever Rack: The Pinnacle of Automated Long Material Storage

In the high-stakes environment of modern industrial warehousing and fabrication, the storage of long, cumbersome materials represents a significant operational challenge. Traditional static shelving and fixed cantilever systems often lead to inefficient use of valuable floor space, arduous manual retrieval processes, and potential safety hazards. Herochu addresses these critical pain points with a revolutionary solution: the professionally engineered Telescopic Cantilever Shelf system. This is not merely a storage rack; it is a transformative automated storage and retrieval system (AS/RS) designed for the specific demands of pipe, tube, metal sheet, and lumber storage.

Representing the next evolutionary step in warehouse optimization, the Herochu system is custom-built to your facility’s exact specifications, starting at $3,099. It is a capital investment that pays for itself through radical gains in space efficiency, workflow velocity, and operational safety. Every component, from the high-tensile steel to the precision-machined bearings, is manufactured under the most stringent international quality assurance protocols, bearing CE, UE, and ISO 9001 certification.

Uncompromising Structural Integrity: Engineered from the Ground Up

The foundational principle of the Herochu Telescopic Cantilever Rack is absolute structural integrity. We understand that the safe storage of heavy, dense materials is non-negotiable.

-

Premium Sourced Raw Materials: The entire structure is fabricated from high-quality carbon steel, sourced from a leading steel group in China. This partnership guarantees material consistency, superior yield strength, and exceptional durability. By controlling quality at the source, we ensure the final product possesses the inherent strength required for heavy-duty industrial applications. This steel is rigorously tested for composition and performance metrics before entering our production line.

-

Precision Fabrication and Advanced Welding: Structural weakness often begins at the joints. Herochu eliminates this vulnerability through advanced dioxygen protection welding techniques. This process results in welding joints with excellent cracking resistance and minimal thermal deformation, ensuring the molecular integrity of the steel is maintained. The welds are not only immensely strong but also aesthetically clean, requiring no post-production slag cleaning. For critical stress points, such as the fixed arm end plate, we employ fully robotic welding. This automated process guarantees pinpoint accuracy, superior penetration, and consistent, repeatable strength that far exceeds what is possible with screw connections or manual welding, eliminating any risk of displacement under load.

-

Professional Design and Cutting: Dimensional inaccuracy in racking systems leads to instability and assembly issues. The Herochu system bypasses this entirely through digital precision. Each column and beam is designed by our professional engineering team using advanced CAD software and then cut by state-of-the-art CNC laser cutting equipment. This ensures that every component, from the main uprights to the smallest connection plate, is produced to exacting tolerances. The laser-cut connection holes on the fixed arm plates are accurate within a remarkable 0.15mm, resulting in a near-seamless assembly with minimal gaps and, consequently, significantly reduced partial load deformation during use.

-

Superior Protective Finish: A storage system must endure the harsh conditions of a workshop—humidity, impact, and abrasion. Herochu’s multi-stage surface treatment process is designed for maximum longevity. Each component undergoes a thorough pre-treatment sequence: chemical oil removal, abrasive rust removal, and phosphating to create a corrosion-inhibiting base layer. A high-grade electrostatic powder coat is then applied and cured in a high-temperature industrial oven. This creates a finish that is exceptionally wear-resistant, scratch-resistant, and impervious to rust, protecting your investment for decades.

Revolutionary Functionality: Manual and Electric Operation

The defining feature of the Herochu system is its telescopic cantilever design, which brings materials to the operator, eliminating the need for dangerous reaching or cumbersome material handling equipment.

1) The Manual Hand-Cranked System: For operations seeking a significant mechanical advantage without a full electrical integration, the hand-cranked model offers unparalleled ease of use. It employs an optimally balanced system of gear and sprocket transmission. The transmission speed ratio is meticulously engineered to distribute mechanical force efficiently. The result is a dramatically reduced hand-cranked shear stress, consistently measuring within a comfortable 120N. This ergonomic design transforms the retrieval of a several-hundred-pound steel tube from a two-person strenuous task into a smooth, one-person operation that is both easy and convenient.

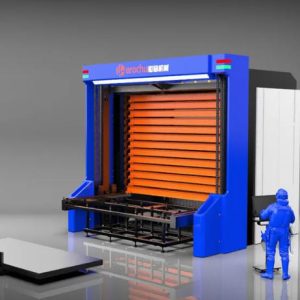

2) The Electric Automated System: This is the apex of storage technology. The electric telescopic cantilever frame is powered by a variable frequency reduction motor integrated with a digital frequency converter. This system is managed via an intuitive touch screen control module, offering both semi-automatic and fully automatic storage and retrieval modes. Operators can command entire rows of arms to extend or retract with the touch of a button, seamlessly integrating with warehouse management systems (WMS). This automation makes the handling of long profiles profoundly simple, convenient, efficient, and seamlessly integrated into a lean manufacturing workflow.

The Critical Advantages of the Telescopic Cantilever Rack System

The adoption of Herochu’s system moves beyond simple storage into the realm of strategic operational improvement.

-

Radical Space Optimization: By utilizing a telescopic design, these racks allow for denser storage configurations. Aisles no longer need to be wide enough for a forklift to access every shelf; materials are telescoped out into the aisle for retrieval. This maximizes vertical and horizontal cube utilization, dramatically increasing storage capacity within the same footprint.

-

Complete Customization: The system is not an off-the-shelf product. It is engineered to your workshop’s specific dimensions, ceiling height, and load-bearing requirements. The adjustable arms can be configured to hold materials of varying lengths and diameters, providing unparalleled versatility to adapt to changing inventory needs.

-

Enhanced Safety and Stability: Safety is engineered into every component. The movable arm bracket utilizes a dual-bearing design, creating a larger force area that effectively minimizes deformation under extreme loads and ensures lower resistance during operation. Furthermore, each rack is equipped with specially engineered leveling pads of varying thicknesses. These are crucial for ensuring the absolute levelness and stability of the entire structure on uneven warehouse floors, preventing any risk of tipping or shifting.

-

Streamlined Workflow and Productivity: The ease of access and retrieval drastically reduces material handling time. Workers spend less time searching for, moving, and maneuvering long materials, leading to faster order fulfillment, reduced labor costs, and a significant boost in overall productivity.

A Recognized Industrial Trend

Market analyses from leading industry research firms consistently identify the steel tube and long-material racking sector as a high-growth area. This growth is directly fueled by the global push for warehouse automation and space optimization. Within this sector, telescopic cantilever racks are frequently highlighted as a key innovation, praised for their direct impact on improving storage density and streamlining material handling processes. Industry consultants and logistics experts endorse these systems for their role in enhancing operational efficiency, reducing product damage, and creating a safer, more organized work environment.

In Conclusion:

The Herochu Telescopic Cantilever Shelf is more than a product; it is a comprehensive storage philosophy made manifest in hardened steel and precision engineering. It represents a departure from outdated, inefficient methods and an investment in a future of automated, safe, and supremely organized material management.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Intelligent Sheet Metal Storage System

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Handling of plates and sheets, vacuum lifting

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Sheet Metal Vacuum Lifting Device

Read moreRated 0 out of 5