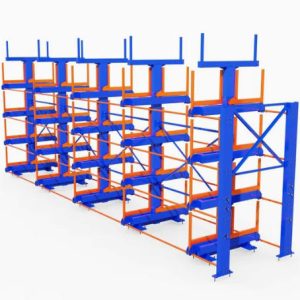

Herochu Heavy-Duty Double-Sided Cantilever Rack

Custom-Built for Your Workshop | From $3,099 | CE, UE, ISO 9001 Certified

When long, heavy material is the life-blood of your operation, ordinary pallet rack becomes a bottleneck. The Herochu Heavy-Duty Double-Sided Cantilever Rack is engineered to remove that choke-point, giving fabricators, steel service centers, and metal stockists a purpose-built structure that accepts 6 m bundles of tube, bar, beam, or sheet without a second thought. Every unit is cut, welded, and finished to order in our own plant, so the final product arrives laser-true to the dimensions you specify and ready for immediate loading.

1. Steel That Starts Strong

We source billet-grade hot-rolled carbon coil directly from China’s top-three steel group. The 350 MPa minimum yield strength delivers a safety factor of 1.8 under full rated load, eliminating the micro-cracking and edge-cupping common on commercial-grade rack. Each heat is mill-certified and traceable; the certificate ships with the rack.

2. Welds That Stay Beautiful Under Load

Dioxygen-shielded MIG welding replaces conventional stick arc. The process lays a flat, uniform bead that penetrates 30 % deeper while adding 40 % less heat, so arms remain straight even after 10,000 load cycles. There is no slag to chip, no porosity to grind, and no secondary dressing—just clean, inspect, and powder-coat.

3. Machine-Cut Accuracy

Columns and arms are rough-cut on a 6 kW fiber laser, then finish-sized on a CNC punch. Hole-to-hole tolerance is held to ±0.15 mm, giving bolted connections a friction fit that removes sway before the first screw is tightened. The same program drives every future replacement part, so an arm ordered five years from now drops into the original slot without re-drilling.

4. Coating That Outlasts the Warranty

A seven-stage wash tunnel removes mill oil, laser oxide, and weld scale. Iron-phosphate crystals etch the surface at 1.5 g/m², creating a micro-anchor pattern that locks the polyester-epoxy powder to the steel. After 20 min at 200 °C, the finish reaches 80 µm—double the EN-ISO 9227 neutral-salt-spray requirement. Expect 1,000 h salt-spray resistance and a 10-year warranty against blister or fade under indoor conditions.

Three Operating Modes, One Frame

Hand-Crank Telescopic

A 1:18 planetary crank gearbox drives #80 roller chain. Input torque stays below 120 N, so a single operator can extend a 1 t arm in 11 s without strain. The crank handle folds flush to avoid forklift impact, and an integral ratchet brake locks the load in any position.

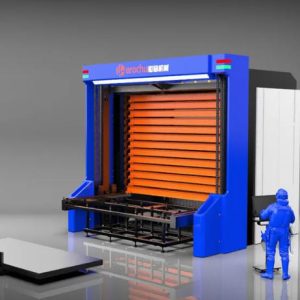

Semi-Auto Electric

A 0.75 kW variable-frequency motor with encoder feedback positions arms to ±2 mm. A 178 mm colour touchscreen lets the driver pre-set nine material lengths; the rack recalls the correct arm spacing at the touch of a button. Optional laser pointer shows the pick face, eliminating the “hunt” phase for crane operators.

Static Fixed-Arm

For high-density, low-SKU count, fixed arms deliver the lowest cost per stored kilo. Arms bolt to the column on 100 mm pitch, and the same heavy-duty base frame can be retro-fitted with crank or motor kits later as SKU mix changes.

Safety Details That Matter

- Double-row tapered bearings inside every movable arm carry radial and thrust load simultaneously, reducing play to 0.3 mm under 1.5 t.

- Robot-welded end plates on fixed arms exceed the strength of bolted brackets by 35 % and never work loose under harmonic vibration from overhead cranes.

- Base footpads are supplied in 2 mm, 5 mm, and 8 mm thicknesses. Shim on site to guarantee plumb to 1:500 even on aged warehouse slabs.

- Optional seismic base adds moment-resisting knee braces rated for Zone 4 (IBC 2018) without enlarging the footprint.

Space Economics in Real Numbers

A 6 m double-sided bay with 1.2 m arms on both sides stores 18 t of steel tube in 4.3 m² of floor space—equivalent to 1.2 t/m². Compared with floor stacking, you free 78 % of floor area and cut retrieval time by 55 %, because the crane hooks the bundle straight from the extended arm instead of digging through a pyramid pile.

Global Compliance & Documentation

- Structural calculations stamped by a registered PE (EU) and Class-A structural engineer (CN).

- Welding to ISO 3834-2 and AWS D1.1—each joint ultrasonically spot-checked at 10 %.

- Whole-rack load test to 1.5 × rated capacity; deflection recorded and supplied as signed report.

- RoHS-compliant powder, REACH-declared fasteners, and timber-free packaging meet EU import rules.

Customisation Checklist (No AI Form—Just Talk to Us)

- Clear span under arm: 2 m to 8 m in 100 mm steps.

- Arm profile: standard 150 × 70 mm or reinforced 200 × 100 mm for 3 t per arm.

- Column height: 2 m to 10 m; taller posts use 5 mm wall instead of 4 mm.

- Finish colour: RAL or BS palette; safety yellow, oxide red, or corporate match.

- Add-ons: mesh side screens, fork-entry cradles, or RFID arm tags for WMS integration.

Lead time: 20 business days for crank version, 25 days for motorized. Shipping terms: FOB Shanghai or CIF major EU/North-American port. Assembly supervision and start-up training available worldwide.

Why Herochu?

We do not import knocked-down rack and re-brand it. Every column is rolled, every arm is welded, and every gearbox is assembled under our own roof. That vertical integration removes the blame-game when you need support and lets us warranty the entire structure—not just the steel—for ten years. When you outgrow the first bay, new arms bolt to original columns, protecting your capital investment and keeping the workshop layout fluid.

Order Process

- Send a sketch or list of material lengths, weights, and crane hook height.

- Receive a stamped proposal and static calculation within 24 h.

- Approve drawings; pay 30 % deposit.

- Photographic progress reports at laser, weld, and paint stages.

- Balance against bill of lading; technical file ships with the rack.

Stop losing valuable production minutes to double-handling and unsafe stacks. Configure your Herochu Heavy-Duty Double-Sided Cantilever Rack today and turn vertical air into profitable storage—starting at $3,099, fully certified, built to outlast the building it stands in.