Automatic Loading and Unloading System for Fiber Laser

To meet the diverse requirements of fabricators, Herochu offers systems in a comprehensive range of standard table sizes, including 3015, 4015, 4020, 6015, 6020, and 6025mm, ensuring a perfect physical match for your laser cutter. Each unit features a multi-level storage magazine, typically offering between 8 and 13 floors. This provides extensive buffer capacity for managing a variety of materials and schedules. Most critically, each of these layers is structurally engineered to support massive weight, with standard load capacities of 3 tonnes and an optional robust 5 tonnes per layer. This immense strength allows for the storage of thick, dense steel plate alongside lighter gauge materials, all within a single, unified automated system.

|

Specification

|

3015/4015/4020/6015/6020/6025mm

|

|

Number of floor

|

8-13

|

|

Load per layer

|

3T/5T

|

|

Mode of movement

|

Linear guide rail + chain

|

|

Transmission mode

|

Chain drive

|

|

Vertical lifting Speed

|

9m/min

|

|

Inlet and outlet Speed

|

12m/min

|

|

Plate Support

|

optional selection

|

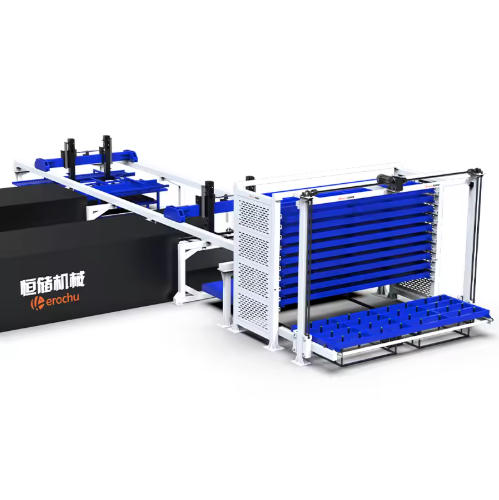

Herochu Automatic Loading and Unloading System for Fiber Laser Cutting: Engineering Unmanned Productivity

In the high-stakes domain of industrial metal fabrication, the true measure of a fiber laser cutting machine’s value extends far beyond its cutting speed and power. Its ultimate worth is defined by its overall throughput—the relentless, consistent flow of material from raw sheet to finished part. This flow is too often constricted by a critical bottleneck: the manual, labor-intensive, and time-consuming processes of loading blank materials and unloading cut components. This reliance on human intervention creates predictable cycles of machine downtime, introduces potential for handling errors, and allocates expensive skilled labor to repetitive physical tasks instead of value-added oversight.

The contemporary manufacturing landscape, characterized by rising operational costs, intense global competition, and a shift towards smaller, customized batch orders, demands a fundamental reorganization of the production floor. The strategic imperative to maintain a competitive edge now hinges on intelligent automation. The Herochu Automatic Loading and Unloading System for Fiber Laser Cutting is not an accessory; it is a transformative operational core. It is engineered to convert your standalone laser cutter into a continuous, integrated, and highly efficient production cell, thereby unlocking the full latent potential of your capital investment and propelling your profitability into a new stratum.

Designed for flawless interoperability with a vast array of fiber laser cutting platforms, the Herochu system serves as the intelligent nexus between raw material storage and the cutting process. It is a paragon of robust industrial engineering, built to deliver unwavering reliability in the most demanding workshop environments. By automating the entire material handling sequence—from supplying pristine sheets to the machine bed to evacuating finished parts and scrap skeletons—we empower your business to achieve unprecedented levels of process reliability, drastically reduce direct labor costs, and facilitate extended periods of lights-out, unmanned production. This results in a monumental increase in Overall Equipment Effectiveness (OEE), delivering a rapid return on investment and securing a formidable market advantage.

Uncompromising Mechanical Design and Operational Prowess

The integrity of an automation system is the bedrock of its performance. Herochu systems are conceived with a philosophy of over-engineering, utilizing premium components to guarantee durability, precision, and steadfast operation under continuous heavy loads.

Precision-Guided Movement and Robust Drive Train: The system’s motion is governed by high-accuracy, hardened linear guide rails. These components ensure absolute translational stability, eliminating any deviation or lateral play during the lifting and traversal of multi-ton loads. This precise movement is coupled with a heavy-duty chain drive transmission, a technology selected for its superior tensile strength, proven longevity, and ability to deliver consistent power transmission over the system’s entire length with minimal maintenance needs. This synergistic combination guarantees that every material handling operation is executed with mechanical certainty and repeatable accuracy.

High-Velocity Performance for Minimized Cycle Times: To complement the blistering speeds of modern fiber lasers, the automation system must operate with commensurate velocity. Herochu systems are engineered for high-speed performance without sacrifice to stability. The vertical lifting mechanism achieves a rapid 9 meters per minute, enabling swift vertical positioning to access any of the multiple storage levels instantly. The critical inlet and outlet sheet transfer mechanism operates at an impressive 12 meters per minute, ensuring the swift exchange of materials between the storage magazine and the laser machine’s chuck system. This high-speed capability is fundamental to slashing non-productive time and maximizing productive laser-on-time.

Substantial Storage Capacity and Configurable Strength: To meet the diverse requirements of fabricators, Herochu offers systems in a comprehensive range of standard table sizes, including 3015, 4015, 4020, 6015, 6020, and 6025mm, ensuring a perfect physical match for your laser cutter. Each unit features a multi-level storage magazine, typically offering between 8 and 13 floors. This provides extensive buffer capacity for managing a variety of materials and schedules. Most critically, each of these layers is structurally engineered to support massive weight, with standard load capacities of 3 tonnes and an optional robust 5 tonnes per layer. This immense strength allows for the storage of thick, dense steel plate alongside lighter gauge materials, all within a single, unified automated system.

Intelligent Material Support and Gentle Handling: Acknowledging that different materials require specific handling protocols, Herochu provides configurable plate support options. These can be tailored to minimize surface contact, thereby preventing scratches and damage to sensitive materials like pre-finished aluminum or polished stainless steel, while still providing the unwavering structural support needed for heavy carbon steel plate. The entire process, often employing an independent vacuum loading and unloading system, is designed for gentleness and precision, ensuring that each sheet is presented perfectly flat and accurately registered for first-time, error-free pickup by the machine.

Functional Sophistication: From Labor Reduction to Full Autonomy

Herochu automation is designed with modular flexibility, providing a scalable path to increased productivity that aligns with your specific operational goals and budget.

The Universal Automation Workhorse: At its core, the system functions as a fully independent loading and unloading unit. It automatically retrieves a raw sheet from its integrated storage magazine and feeds it precisely onto the laser machine’s bed. Upon completion of the cutting cycle, it reverses the process, entering the machine to unload the entire table. Advanced systems can facilitate the separation of cut parts from the scrap skeleton directly on the machine bed or on an auxiliary table. This core functionality alone eliminates the most physically demanding and time-consuming manual tasks, enabling a single operator to supervise multiple laser cells with ease.

Integrated Storage and Agile Production Management: The multi-level storage unit is not merely a rack; it is an intelligent buffer that drastically improves workshop organization and space utilization. It allows for the pre-loading of multiple material types and thicknesses, facilitating quick job changeovers and drastically reducing setup downtime. The system often features an automatic loading platform with direct forklift coupling, a critical feature for the rapid insertion of urgent orders or special materials without disrupting the automated cycle of pre-loaded sheets.

Seamless Integration and Smart Communication: For true industrial-grade performance, seamless machine communication is essential. Herochu systems utilize advanced EtherCAT Bus communication protocols. This high-speed, deterministic industrial Ethernet standard facilitates deep, real-time integration with the laser cutting machine’s CNC and other factory automation systems. This enables a perfectly synchronized workflow, sophisticated production scheduling, and remote monitoring capabilities, forming the cornerstone of a smart, Industry 4.0-ready manufacturing cell.

The Concrete Returns on Your Automation Investment

Implementing a Herochu Automatic Loading and Unloading System translates into direct, quantifiable benefits that fundamentally improve your business metrics.

Radical Increase in Machine Utilization and Output: By eradicating loading and unloading downtime between sheets, your laser cutter’s spindle-on-time can increase dramatically—often by 40% or more. This effectively creates additional production capacity from your existing machine, allowing you to accept more orders and increase revenue without the capital outlay for a second laser.

Profound Labor Optimization and Cost Reduction: Automating the material handling process allows you to reallocate skilled welders and machine operators to more productive tasks such as programming, part finishing, welding, and assembly. This reduces your dependency on difficult-to-source manual labor, mitigates the impact of rising wage costs, and minimizes workplace fatigue.

Enhanced Operational Safety and Process Consistency: Removing personnel from the direct handling of heavy, sharp-edged sheets significantly enhances workshop safety, reducing the risk of costly accidents. Furthermore, automated handling is inherently precise and consistent, eliminating the human errors that lead to material misalignment, scrapped parts, head crashes, and other expensive mishaps.

Superior Material Management and Traceability: The system provides organized, designated, and protected storage for raw materials, reducing floor clutter and minimizing the potential for damage or mix-ups. When integrated with a Manufacturing Execution System (MES), it can provide full material traceability, logging which specific sheet was used for which production job, thereby enhancing quality control and production accountability.

Certified Quality and Global Manufacturing Pedigree: Every Herochu system is manufactured under a rigorous quality management system certified to ISO 9001, ensuring exceptional consistency and reliability. Our products are CE marked, guaranteeing full compliance with the stringent health, safety, and environmental protection directives of the European Union. As a direct manufacturer, Herochu provides exceptional value, with highly customizable solutions starting at $8,900, making advanced, industrial-grade automation an attainable and shrewd investment for forward-thinking fabricators.

Specification Overview:

-

Brand Name: Herochu

-

Product Name: Automatic Loading and Unloading System for Fiber Laser

-

Compatible Sizes: 3015, 4015, 4020, 6015, 6020, 6025mm

-

Storage Floors: 8-13 Levels

-

Load Capacity: 3T or 5T per Layer

-

Movement Mode: Linear Guide Rail + Chain

-

Transmission: Chain Drive

-

Lifting Speed: 9 m/min

-

Inlet/Outlet Speed: 12 m/min

-

Plate Support: Optional Configurations

-

Communication: EtherCAT Bus

-

Certification: ISO 9001, CE, EU

-

Starting Price: $8,900 (Customizable)

Stop letting manual handling limit your profitability. Contact Herochu today to schedule a detailed consultation and receive a comprehensive proposal for an automation system engineered to maximize the productivity, safety, and return on investment of your fiber laser cutting operations.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Loading/unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading System for Fiber Laser

Read moreRated 0 out of 5 -

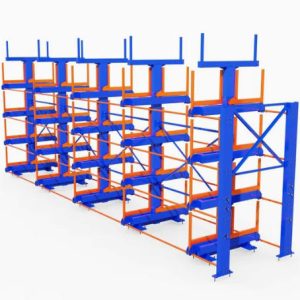

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5 -

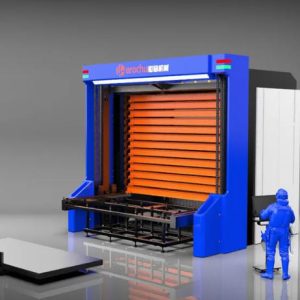

Automated Sheet Metal Storage Systems

Intelligent Sheet Metal Storage System

Read moreRated 0 out of 5