Heavy-Duty Sheet Metal Storage Racks

Herochu Heavy-Duty Sheet Metal Storage Racks are engineered to be that solution. This is not merely shelving; it is a comprehensive range of advanced storage systems designed to transform chaotic storage into a model of efficiency, safety, and space optimization. By leveraging innovative designs like horizontal roll-out drawers and high-density vertical towers, Herochu systems bring unparalleled organization and ergonomic access to the most challenging storage environments. For industrial workshops, fabrication shops, and large-scale material handling centers, this translates directly into reduced labor costs, maximized space utilization, protected material investments, and a dramatic acceleration in workflow throughput. It is an investment that pays continuous dividends in productivity and safety.

|

Model

|

HC-B3015-61

|

HC-B3015-62

|

HC-B3015-63

|

|

Weight/layer (kg)

|

1,000

|

2000

|

3000

|

|

Total load(KG)

|

6000

|

12000

|

18000

|

|

number of Layer

|

6

|

6(customizable)

|

6(customizable)

|

|

Panel size(m)

|

3×1.5

|

3×1.5

|

3×1.5

|

|

weight(t)

|

1.6

|

1.8

|

2.2

|

|

storey height(mm)

|

220

|

220

|

220

|

Herochu Heavy-Duty Sheet Metal Storage Racks: Engineering Maximum Density and Uncompromised Accessibility

Within the high-velocity environment of modern metal fabrication and manufacturing, raw material storage is frequently the most significant bottleneck to overall productivity and profitability. The challenges presented by storing, protecting, and retrieving heavy sheet metal, steel plate, and other planar materials are universal pain points: valuable production floor space consumed by disorganized leaning stacks, the significant safety risks and ergonomic strain of manual handling, the frustrating damage to expensive pre-finished materials, and the costly time lost searching for specific sheets buried within a stack.

Conventional storage methods, such as simple racking or floor stacking, are no longer sufficient for operations serious about lean manufacturing and operational excellence. These outdated practices represent a hidden cost center, silently eroding margins through inefficiency and risk. The solution requires a fundamental rethinking of storage from a passive holding area into an active, integrated component of the material handling workflow.

Herochu Heavy-Duty Sheet Metal Storage Racks are engineered to be that solution. This is not merely shelving; it is a comprehensive range of advanced storage systems designed to transform chaotic storage into a model of efficiency, safety, and space optimization. By leveraging innovative designs like horizontal roll-out drawers and high-density vertical towers, Herochu systems bring unparalleled organization and ergonomic access to the most challenging storage environments. For industrial workshops, fabrication shops, and large-scale material handling centers, this translates directly into reduced labor costs, maximized space utilization, protected material investments, and a dramatic acceleration in workflow throughput. It is an investment that pays continuous dividends in productivity and safety.

The Herochu Philosophy: Engineered for Industrial Rigor

At the core of every Herochu storage system is a commitment to over-engineering and durability. We understand that industrial equipment must withstand constant use under immense loads for decades.

Unmatched Structural Integrity: Every frame is constructed from high-tensile strength steel, meticulously welded by certified professionals to create a unified, immensely strong structure. Critical stress points are reinforced to prevent deflection or deformation, even when operating at maximum rated capacity. This robust foundation ensures the system’s longevity and unwavering stability, protecting both your stored materials and your personnel.

Advanced Protective Finishes: To endure the harsh conditions of a working workshop—including humidity, airborne particulates, and occasional impacts—every component undergoes a rigorous multi-stage surface preparation process. This is followed by the application of a high-grade electrostatic powder coating. This finish provides superior resistance to corrosion, abrasion, and chemicals, ensuring the rack maintains its structural and aesthetic integrity for years. The result is a product that is as durable as it is functional.

Certified Safety and Quality: Herochu systems are manufactured under a quality management system certified to ISO 9001, guaranteeing consistency and excellence in every unit. Furthermore, our products are CE marked, demonstrating full compliance with the stringent health, safety, and environmental requirements of the European Union. This certification provides peace of mind that you are investing in equipment that meets the highest global standards for safety and performance.

A System for Every Application: The Herochu Product Range

Recognizing that no two facilities have identical needs, Herochu offers a diversified portfolio of storage solutions, each engineered to solve specific challenges.

1. Horizontal Roll-Out Sheet Metal Racks: The Epitome of Ergonomic Access

This system represents the pinnacle of accessible, ground-level storage. Featuring between three and eight heavy-duty shelves mounted on full-extension drawer slides, it allows every single sheet to be accessed directly and effortlessly without moving any other material.

Deep-Dive Features and Benefits:

-

Full Extension Ergonomic Guides: Each shelf glides smoothly on industrial-grade rollers and guides, extending completely to provide 100% overhead clearance. This allows for safe and easy loading and unloading using overhead cranes, forklifts, or vacuum lifters, eliminating dangerous man-handling.

-

Automatic Locking Mechanism: When closed, each drawer automatically engages a locking mechanism, securing the load during transport and preventing accidental opening that could pose a safety hazard.

-

Exceptional Load Capacity: Each shelf is rated to handle an impressive 5,500 lbs (approx. 2,500 kg), making it suitable for the heaviest steel plates and large sheet stacks.

-

Customizable Configuration: While a standard 7-foot height is common, these racks are fully customizable. Options include folding security doors, double-sided loading for aisle access from both sides, forklift risers for easy mobility, and custom shelf sizes to fit any material dimension.

-

Integrated Side Rails: These provide critical support to the shelf during extension, preventing any tipping or binding under asymmetric loads and ensuring buttery-smooth operation every time.

2. Forklift Stacker Horizontal Sheet Racks: Ultimate Flexibility and Mobility

For operations that require frequent reorganization or mobile storage solutions, the Forklift Stacker system is ideal. Essentially a series of robust, removable pallet-style shelves with integrated fork pockets, this design allows a single forklift operator to manage entire storage units.

Deep-Dive Features and Benefits:

-

Removable Pallet-Style Shelves: Each of the 10 to 19 shelves is a self-contained unit, enabling incredible flexibility. Shelves can be added, removed, or rearranged to accommodate materials of different heights and weights.

-

Built-In Fork Pockets: The integrated design allows a standard forklift to easily pick up and move entire loaded shelves, facilitating dynamic storage management and easy transport of materials to different areas of the shop floor.

-

High Capacity and Customization: With a standard capacity of 5,000 lbs per shelf and options for even higher ratings, these units handle serious weight. The spacing between shelves and the overall rack width can be customized to meet precise storage requirements, from thin aluminum sheets to thick steel plate.

-

Powder-Coated Welded Steel: Constructed from the same durable materials as our static racks, these mobile units are built to withstand the rigors of both storage and transportation.

3. Vertical Roll-Out Sheet Metal Racks: Maximum Density Storage

When floor space is at an absolute premium, the vertical storage tower is the ultimate solution. These systems stack between eight and twenty-five shelves vertically, utilizing height rather than footprint to achieve incredibly high storage density.

Deep-Dive Features and Benefits:

-

High-Density Footprint: By storing materials vertically, these racks can save over 50% of the floor space required by traditional horizontal storage methods, freeing up valuable square footage for additional machinery or production space.

-

Full-Extension Vertical Access: Despite their height, each shelf is designed to pull out completely, providing the same full overhead access as the horizontal models. This ensures that no sheet is ever trapped behind another.

-

Optimized for Overhead Handling: The design is perfectly suited for integration with overhead cranes, hoists, or vacuum lifters. Operators can efficiently retrieve any sheet from the stack without manual labor, drastically reducing handling time and ergonomic strain.

-

Robust Load Handling: Each shelf boasts a substantial load capacity of up to 2,000 lbs, and the entire structure is engineered to manage this weight at height with complete stability and safety.

The Tangible Return on Investment

Implementing a Herochu storage system delivers measurable benefits that directly impact your bottom line.

-

Radical Space Savings: By storing materials vertically and eliminating the aisles needed for traditional access, Herochu racks can reduce your storage footprint by over 50%, effectively doubling your available space without expanding your facility.

-

Dramatic Reduction in Handling Time: Ergonomic roll-out shelves eliminate the dangerous and time-consuming process of digging through stacks. Retrieval time per sheet can be reduced from minutes to seconds, significantly accelerating project timelines.

-

Complete Material Protection: Sheets are stored flat and individually supported, preventing the warping, scratching, and edge damage caused by leaning stacks or improper handling. This minimizes costly material waste and rejects.

-

Enhanced Inventory Visibility and Control: An organized rack system makes inventory management simple. Every sheet is visible and accessible, eliminating loss and making stock-taking a quick and accurate process. This visibility helps minimize over-ordering and reduces capital tied up in excess inventory.

-

Significant Improvement in Workplace Safety: The elimination of manual sheet handling and unstable leaning stacks drastically reduces the risk of crushing injuries, musculoskeletal disorders, and other common workshop accidents. Automatic locking mechanisms and stable structures create a inherently safer work environment.

Specification Overview:

-

Brand Name: Herochu

-

Product Name: Heavy-Duty Sheet Metal Storage Racks

-

Types: Horizontal Roll-Out, Forklift Stacker, Vertical Roll-Out

-

Load Capacity: Up to 5,500 lbs per shelf (Horizontal), 5,000 lbs (Forklift Stacker), 2,000 lbs (Vertical)

-

Construction: Welded Steel Frame with Powder Coat Finish

-

Features: Full Extension Shelves, Automatic Locking, Customizable Configurations, Fork Pockets (Stacker)

-

Certification: ISO 9001, CE, EU

-

Starting Price: $8,900 (Fully Customizable)

Stop allowing inefficient storage to constrain your productivity and inflate your costs. Contact Herochu today to schedule a consultation with our storage experts. We will analyze your specific workshop layout, material profile, and workflow needs to provide a detailed proposal for a Heavy-Duty Sheet Metal Storage Rack system engineered to organize your space, protect your assets, and power your productivity.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Loading/unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading System for Fiber Laser

Read moreRated 0 out of 5 -

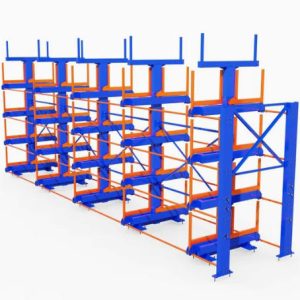

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5 -

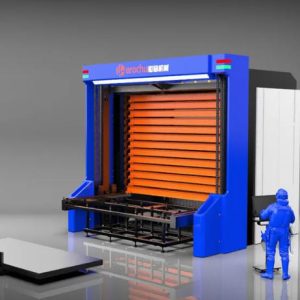

Automated Sheet Metal Storage Systems

Intelligent Sheet Metal Storage System

Read moreRated 0 out of 5