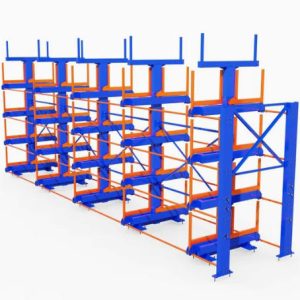

Herochu Storage Racking System for Metal Sheets

From $3 099, CE/EU/ISO 9001 verified, cut floor space in half while lifting 2.5 t per shelf

Sheet metal is not inventory you can stack like boxes; one scratched face turns an expensive blank into expensive scrap. Herochu storage racking system for metal sheets keeps every plate, remnant and off-cut off the floor, off the wall and out of harm’s way. Pick the format that matches your crane, your forklift or your bare hands—horizontal roll-out, forklift stacker or vertical pull-out—and gain back the square metres you are already paying rent on.

Built for the weight of real stock

The chassis begins as 6 mm hot-rolled S355 laser-cut plate, fully welded then stress-relieved at 600 °C to stop memory creep. Beams are 220 × 80 × 6 mm C-section, moment of inertia 1 680 cm⁴, so a 2 500 mm bay carrying 2 500 kg deflects less than 1/1 000 of span. Uprights are 100 × 100 × 5 mm box, punched on 50 mm pitch so shelf height can be moved in two minutes without drilling new holes. Every weld is magnetic-particle tested; the only acceptable defect is none.

Horizontal roll-out racks—crane friendly

Each shelf runs on four sealed flange wheels, Ø 160 mm, 6204-2RS bearings, inside a 14 mm cold-rolled rail. A 2 500 kg sheet needs only 22 daN pull force; the shelf locks closed with a spring-loaded shoot-bolt and locks open at full extension so the crane hook can work overhead. Side cheeks are 60 mm high to stop sheets from drifting; cheeks flip down if you need to overhang material for slings. Standard height is 2 100 mm (seven shelves) but we supply everything from three tiers to eight, 1 000 mm wide to 3 000 mm wide. Powder coat is RAL 5015 traffic blue, 80 µm, salt-spray tested 1 000 h to ISO 9227; galvanised or stainless finish is available for coastal or food-grade halls.

Forklift stacker racks—one truck, one operator

Ten to nineteen removable pallets sit on welded fork pockets so the truck lifts the shelf out, sets it on the floor for loading, then returns it to the rack. Pockets are 200 mm high, 1 200 mm long, positioned so the shelf centre of gravity stays within 400 mm of the fork face—no tipping, no blind spots. Each pallet is rated 2 500 kg UDL; if you need 5 000 kg we double the longitudinal rails and keep the same pocket spacing so existing trucks still fit. Pallets are numbered with high-vis vinyl tags; a 40 × 40 mm pocket accepts a bar-code holder for ERP integration.

Vertical pull-out racks—gravity on your side

Eight to twenty-five shelves hang from twin 25 mm induction-hardened shafts, running in graphite-bronze bearings that never need grease. Pull the handle and the shelf tilts 15° downward, so the sheet edges clear the shelf above and the crane can hook from above without diagonal dragging. A gas spring cushions the last 200 mm of travel; close the shelf and a detent auto-locks. Load per shelf is 1 000 kg as standard, 2 000 kg on request by upgrading to 30 mm shafts. Total depth is only 1 100 mm for a 6 m shelf, freeing aisle width for narrow trucks.

Floor footprint cut by half

A traditional A-frame for 100 t of mixed sheet needs roughly 90 m² plus 4 m aisles on both sides. A Herochu horizontal roll-out rack of the same capacity occupies 42 m² and needs only one 3.5 m aisle. At €65/m² annual rent the saving is €3 120 every year—more than the depreciation on the rack. Add the drop in scratch rejections and the payback is usually under twelve months.

Handles every size you stock

- 0.5 mm mirror finish stainless—PVC-coated shelves prevent slip marks

- 25 mm wear plate—5 000 kg shelf option with no deflection

- 4 m × 2 m oversized sheet—shelf width 2 100 mm, extension 1 150 mm, crane clearance 850 mm

- 200 × 400 mm remnant—adjustable dividers create 100 mm pockets so small pieces never disappear

Sheet separators are 50 mm high, laser-cut from 3 mm steel, powder-coated to match the rack. Remove them when you store 6 m bars or 12 m cladding coils; the same frame accepts both.

Options that make the rack yours

- Folding mesh doors with key lock—keep high-value copper or brass secure

- Grounding lugs for ATEX zones—dissipate static when you store titanium or carbon fibre

- Roller conveyor insert—push-feed directly into a shear or fibre laser without a second lift

- Digital load cell—displays real-time weight on a 25 mm LED, exports CSV for inventory

- Colour code strips—choose red for hot-rolled, blue for aluminium, yellow for stainless; operators find the right shelf without reading

Certifications that open every market

Racks carry full EU Declaration of Conformity to EN 1993-1-1 steel structures, EN 13105 static storage and EN 15620 removable pallets. ISO 9001:2015 (quality) and ISO 14001:2018 (environment) are renewed annually; certificates ship with every order. If you need TÜV or UKCA marking we supply the test dossier and witness the load test at your site—no third-party inspector invoice surprises.