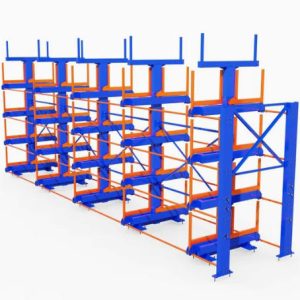

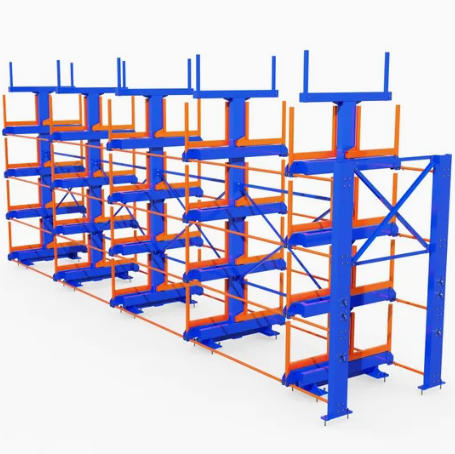

Herochu Extractable Cantilever Shelves for Long Goods

Slide 12 m of steel, timber or plastic out of the rack as easily as opening a desk drawer—custom-built from $3 698, shipped with CE, EU and ISO 9001 papers intact.

Every workshop, port-side warehouse and timber yard hits the same invisible wall: long goods eat floor space faster than they earn revenue. Bar stock leans against fire doors, plywood bridges across aisles, PVC pipe hides behind rebar, and the morning shift spends the first hour moving last night’s leftovers just to reach today’s cutting list. Herochu extractable cantilever shelves remove that wall. One operator, one hoist or vacuum lifter, one smooth pull, and the full bundle glides out at waist height—no fork-lift ballet, no hunting, no dented edges, no scratched coatings. From 3 m hardwood planks to 12 m stainless tube, the system turns vertical air into organised, dense, instantly accessible storage that keeps pace with saws, lasers, press brakes and delivery trucks.

Why extractable beats static

Traditional cantilever arms force the crane to reach between columns, often dragging material sideways and scuffing the finish. Herochu arms ride on sealed linear bearings rated for 30 000 cycles at full load. They extend 600 mm–1 200 mm, presenting the bundle clear of the rack so an overhead crane can lift straight up. Push the arm back and it locks home with a tapered wedge pin plus cotter clip that cannot drift under shock load. The aisle width collapses to the depth of one open arm—under 1 m—so you reclaim up to 60 % of floor area for value-adding machinery while eliminating the hand-to-hand combat that damages stock and endangers staff.

Built for the weight of real work, not brochure numbers

Columns are laser-cut from 8 mm hot-rolled H-section steel, minimum yield 355 N/mm², and welded to a 12 mm base plate that spreads load across four M20 anchor bolts grade 8.8. Arms are fabricated from 6 mm wrap-around channel with a 240 mm connector plate gusset. The result: a single side can support 2 000 kg per level; freestanding towers can climb to 10 m without rear bracing clashing with roof trusses. Arms adjust vertically in 100 mm increments, so tomorrow’s 450 mm deep glulam beam can replace today’s 200 mm plastic conduit bundle in minutes, not hours. Optional hot-dip galvanising after fabrication adds 70 µm zinc coating both inside and outside hollow sections, meeting EN ISO 1461 for outside storage yards where UV, rain and forklift tyres are part of the climate.

Cold-rolled precision, powder-coated armour

After shot-blasting to Sa 2.5, every component receives cathodic electro-primer followed by 80 µm polyester powder in any RAL colour. The finish passes 1 000 h neutral-salt-spray, making it suitable for coastal humidity or the daily steam clean demanded by food-grade timber mills. A 160 °C bake ensures adhesion that resists fork-truck scrapes and chemical wash-down for at least fifteen years.

Extend, relocate, re-arm—zero disposal cost

Start with a single-sided starter bay 3 m high × 800 mm arm. Add double-sided add-on bays as turnover grows. Need longer arms? Swap 1 m for 1.5 m bolt-on sections while the rack remains loaded. Move premises? Unbolt columns from base plates, palletise and reinstall—no on-site welding, no concrete cutting. The modular design follows you for decades, eliminating the scrap-and-replace cycle that erodes capital budgets.

Safety engineered, not retro-fitted

A tapered wedge pin plus cotter clip locks each arm to the column; the assembly cannot loosen under vibration. A 120 mm lip at the arm nose stops round bar from rolling, while replaceable PE face strips protect polished architectural aluminium. Columns are pre-drilled for mesh or timber decking, converting cantilever levels into solid shelves for boxed extrusions or outdoor pallets. Base plates include pre-marked anchor templates so installers hit exact centre-lines first time—no field measuring, no mis-aligned towers. A flush-mounted level bubble guarantees plumb to within 1:500, removing the twist that shortens bearing life.

Density by numbers—worked example

Take a 9 m long pack of 200 × 75 mm timber—weight 1.8 t. Traditional block stacking needs 12 m² and allows only top-down turnover. One double-sided Herochu bay 3 m high × 1 m arms on both sides stores twelve packs in 5 m²—delivering 4.8× material density and 58 % reduction in floor usage. Multiply by your rent per square metre and the rack self-finances in months, not years.

Indoor or outdoor—same ten-year warranty

Optional hot-dip galvanising after fabrication adds 70 µm zinc coating both inside and outside the hollow sections, meeting EN ISO 1461. The structure tolerates –30 °C frost and +50 °C sun without de-lamination, making it a favourite for Middle-East pipe distributors and Scandinavian timber terminals alike.

Plug-and-play with existing workflows

Saw lines: Position the rack so extended arms align with in-feed rollers; one crane movement transfers bar to saw bed without double handling.

Tube mills: Store mother coil on the top level, finished pipe on lower levels; arms roll out to match mill run-out table height.

Furniture factories: Keep 2.8 m MDF boards on decked arms beside CNC router; no clamp truck required.

Overnight security: Lock arms closed with a single padlock bar threaded through wedge-pin eyes, eliminating loose stock temptation.

Certified, traceable, insured

We certify every weld to EN ISO 3834-2, dimensionally check towers to ±2 mm, and supply mill certificates for all raw steel. The finished structure is CE-marked under Machinery Directive 2006/42/EC and carries EU-type examination for 2 000 kg per arm. A $5 million global product liability policy underwritten by PICC guarantees structural integrity for ten years under normal workshop conditions.

Smart options that future-proof your investment

- Motorised arm: 0.75 kW linear actuator with pendant control reduces extension force to 5 kg—ideal for delicate composite panels.

- Load cell column: Each arm becomes a live scale; gross/net weights feed to your ERP via Modbus TCP.

- LED traffic light: 24 V stack-light shows green when arm is locked out, red when unlocked—visual management for night shift.

- Rear cladding: 1.5 mm corrugated steel sheets bolt between columns, creating a weather-proof cage for outdoor yards.

- RFID magazine: Laser-etched polymer tags rivet to arm noses; scan with a tablet to update inventory in real time.

What you receive

- Factory acceptance video and 125 % load test report within 10 working days of order.

- Anti-rust vacuum wrap, plywood crate, steel strapped, ocean-ready.

- Digital anchor template, torque chart and bilingual installation manual.

- Ten-year structural warranty plus lifetime hardware replacement promise.

Talk to a storage engineer today

Email a sketch of your longest load, heaviest bundle and clear height. We will return a footprint drawing, arm configuration and firm quotation within 24 hours. Whether you run a rural timber yard or a high-speed tube mill, Herochu extractable cantilever shelves turn the space you fight against into the profit you scale upon.