Pull Out Sheet Storage Drawer Rack Roll-Out Sheet Rack for Sheets

Herochu, a leader in engineered industrial storage solutions, directly confronts these challenges with our innovative Pull Out Sheet Storage Drawer Rack. This system is not a simple shelving unit; it is a sophisticated, high-capacity storage ecosystem engineered to transform chaotic storage areas into models of order, safety, and efficiency. Designed for the seamless integration into modern workshops and warehouses, the Roll-Out Sheet Rack provides instant, full-access retrieval of every sheet in your inventory, eliminating the traditional drawbacks of sheet storage. As a cornerstone of the automated Sheet Metal Automatic Material Warehouse concept, this system is a pivotal investment in enhancing productivity, optimizing spatial economics, and safeguarding your valuable assets, with a starting investment of $3,698.

Herochu Pull Out Sheet Storage Drawer Rack: Revolutionizing Industrial Material Handling

In the demanding world of sheet metal fabrication, industrial manufacturing, and large-scale woodworking, the storage and retrieval of raw sheet materials represent a significant operational bottleneck. Traditional storage methods, such as leaning sheets against walls or stacking them in static racks, are fraught with inefficiency, consume valuable floor space, and present substantial safety risks to personnel and materials alike. These outdated systems lead to damaged inventory, difficult access, and wasted man-hours as workers struggle to locate and extract specific sheets from the middle of a heavy stack.

Herochu, a leader in engineered industrial storage solutions, directly confronts these challenges with our innovative Pull Out Sheet Storage Drawer Rack. This system is not a simple shelving unit; it is a sophisticated, high-capacity storage ecosystem engineered to transform chaotic storage areas into models of order, safety, and efficiency. Designed for the seamless integration into modern workshops and warehouses, the Roll-Out Sheet Rack provides instant, full-access retrieval of every sheet in your inventory, eliminating the traditional drawbacks of sheet storage. As a cornerstone of the automated Sheet Metal Automatic Material Warehouse concept, this system is a pivotal investment in enhancing productivity, optimizing spatial economics, and safeguarding your valuable assets, with a starting investment of $3,698.

The Engineering Philosophy Behind Herochu’s Roll-Out Rack System

The foundational principle of the Herochu Pull Out Sheet Storage Drawer Rack is the combination of robust structural integrity with intelligent, ergonomic access. Every component is meticulously designed and manufactured to meet the most rigorous international standards, evidenced by its CE, EU, and ISO 9001 certifications. This certification triad is your absolute assurance of a product that has been designed, tested, and proven to perform safely and reliably in an industrial environment.

The primary framework is constructed from high-grade, cold-rolled steel, selected for its exceptional strength and durability. This material provides the necessary structural backbone to support immense weight capacities without deflection or deformation, ensuring the system remains stable and secure even when fully loaded. Beyond raw strength, the steel undergoes a comprehensive protective process. It is first pickled and phosphated to ensure optimal surface preparation before receiving a thick, resilient electrostatic powder coating. This finish is thermally cured to create a barrier that is highly resistant to impact, abrasion, and corrosion, protecting the investment from the harsh environmental factors present in workshops, including humidity, dust, and incidental contact.

Addressing Core Storage and Handling Problems with Purpose-Built Solutions

The conventional method of storing sheets requires moving several heavy, often sharp-edged plates to access the one needed. This process is not only time-consuming but also dangerously increases the risk of workplace injuries such as musculoskeletal strains, lacerations, and crushing incidents. The Herochu Roll-Out Rack system is engineered to eliminate these problems entirely.

Each storage tier is equipped with a full-extension, heavy-duty sliding drawer mounted on industrial-grade roller systems. This design allows each drawer to glide smoothly and effortlessly, providing complete, unobstructed access to every single sheet stored within. There is no more need to lift, shuffle, or manhandle other materials. An operator can simply approach the unit, identify the required sheet, pull out the corresponding drawer, and retrieve the material directly and safely. This streamlined process drastically reduces retrieval time, minimizes physical exertion, and virtually eliminates the risk of damage to the sheets’ precision edges and surfaces, thereby protecting your material investment and reducing waste.

An In-Depth Look at System Advantages and Operational Benefits

The advantages of integrating the Herochu Pull Out Sheet Storage Drawer Rack into your material workflow are extensive and directly impact your bottom line.

-

Uncompromising Load Capacity and Structural Integrity: The system is engineered from the ground up for heavy-duty performance. The reinforced steel frame and high-load-bearing drawer slides are capable of supporting substantial weight, allowing for the safe storage of even the densest metal sheets. The design ensures stability is maintained at all times, whether the drawers are fully retracted or fully extended, providing operators with complete confidence.

-

Revolutionary Space Utilization and Optimization: By leveraging vertical space that is typically underutilized, the Herochu rack system creates a dense, three-dimensional storage footprint. This high-density approach can effectively double or triple your storage capacity within the same floor area, freeing up invaluable square footage for additional machinery, production cells, or workflow pathways. This is a direct answer to the spatial constraints faced by growing businesses.

-

Enhanced Safety as a Standard Feature: Safety is not an optional extra; it is embedded in the design. The system includes a standard buffer damper mechanism that ensures drawers glide to a smooth and controlled stop at the end of their travel, preventing violent impacts and reducing wear on components. Furthermore, by removing the need for climbing, reaching, or awkward lifting, the rack actively reduces the potential for work-related injuries, contributing to a safer corporate culture and reducing potential liability.

-

Advanced Automation and Control Integration: For facilities requiring the pinnacle of efficiency, the system can be integrated with advanced automation components. This includes a robust bus system and an absolute value servo motor, which provides strong anti-interference ability and eliminates the need for a time-consuming homing sequence upon every startup. Faster transmission speeds and a standard teach pendant allow for quick, offline programming and remote control operation, bringing true Industry 4.0 capabilities to your storage process.

-

Inherent Flexibility and Future-Proof Design: Recognizing that manufacturing needs evolve, the Herochu rack system is fundamentally modular and adaptable. The units can be reconfigured, expanded, or repurposed as your storage requirements change. This modularity means you will never need to abandon or completely rebuild your storage infrastructure; it can grow and adapt in lockstep with your business, protecting your long-term investment.

Customization: A Tailored Solution for Your Unique Workshop

Acknowledging that every facility has unique spatial and material requirements, the Herochu Pull Out Sheet Storage Drawer Rack is fully customizable to your workshop. Our engineering team collaborates with you to design a system that perfectly fits your available dimensions and storage needs. Critical parameters such as overall height, width, depth, the number of drawers, and the individual load capacity of each tier can all be tailored to create your ideal storage solution. You can provide a CAD drawing for a rapid quotation, or simply share the dimensions of your available space, and our design specialists will produce a customized layout and proposal within a 48-hour timeframe. OEM and ODM services are also readily available.

Ideal Applications and Industries

The Herochu Pull Out Sheet Storage Drawer Rack is the optimal storage solution for a wide range of flat, sheet-based materials, including:

-

Sheet metal (steel, aluminum, stainless steel, copper)

-

Plastic sheets (polycarbonate, acrylic, HDPE)

-

Glass panels and composite materials

-

Wood panels (plywood, MDF, particle board)

-

Industrial laminates and solid surface materials

It is an indispensable asset for industries such as metal fabrication, aerospace manufacturing, automotive prototyping, custom furniture and cabinetry production, and sign-making.

Conclusion: An Investment in Efficiency, Safety, and Growth

The Herochu Pull Out Sheet Storage Drawer Rack is more than a piece of equipment; it is a strategic upgrade to your operational infrastructure. It directly addresses the critical pain points of material handling—saving time, saving space, preventing injuries, and protecting inventory. By streamlining the storage and retrieval process, it unlocks new levels of productivity and allows your skilled workforce to focus on value-added tasks rather than logistical challenges.

For business leaders and facility managers dedicated to continuous improvement, this system offers a compelling return on investment through tangible gains in efficiency and safety. To explore how this system can be customized for your specific application and to receive a detailed quote, contact the Herochu engineering team today. Transform your material storage from a liability into a competitive advantage.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Manual Control Roll out Sheet Metal Rack with Forklift

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Pull Out Sheet Storage Drawer Rack Roll-Out Sheet Rack for Sheets

Read moreRated 0 out of 5 -

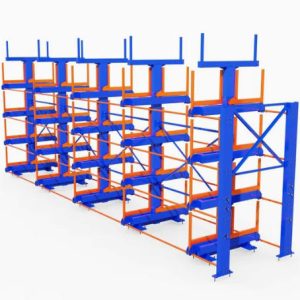

Heavy Duty Cantilever Racking System

Customizable Workshop Storage Cantilever Racking System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading/unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading System for Fiber Laser

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5