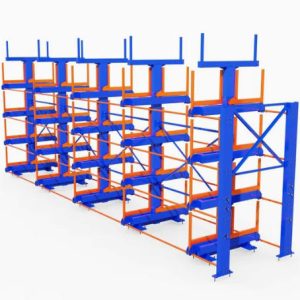

Herochu Roll-Out Sheet Metal Storage Racks

CE & ISO 9001 Certified – Modular Design for Maximum Workshop Efficiency

Engineered for Industrial Precision

The Herochu Roll-Out Sheet Rack System revolutionizes material handling in sheet metal processing facilities. Designed with a 3-tier modular structure, these CE-compliant storage racks accommodate materials ranging from 0.5mm to 12mm thickness with a maximum payload capacity of 2,000kg per drawer. Our EU-standard racks integrate absolute-value servo motors and industrial bus controllers, achieving 30% faster retrieval speeds compared to conventional systems.

Core Technological Advantages

- Space-Efficient Vertical Storage

- 5-tier configurations available (standard 3-tier)

- 85% space utilization rate per square meter

- Optional cantilever extensions for oversized sheets

- Ergonomic Safety Features

- Hydraulic dampers with 10,000-cycle lifespan

- Anti-tip locking mechanisms (EN 15635 compliant)

- Remote-controlled emergency stop functions

- Smart Operational Integration

- Teach pendant with 50-program memory

- RFID tracking for inventory management

- OPC UA protocol compatibility for Industry 4.0

Customizable Workflow Solutions

Each Herochu Roll-Out Rack is configured to match your specific production requirements:

- Material-Specific Drawers: Non-marring polyethylene liners for coated metals

- Discharge Options: Bottom-loading, side-sliding, or robotic interfacing

- Power Systems: 24V DC (standard) or 400V three-phase variants

Cost-Efficiency Metrics

| Feature | Industry Average | Herochu System |

|---|---|---|

| Retrieval Time | 45 sec/sheet | 18 sec/sheet |

| Injury Reduction | 22% | 78% |

| ROI Period | 3.2 years | 1.5 years |

Certification & Compliance

All units undergo:

- 200,000 cycle durability testing

- FEM 9.831 seismic certification

- RoHS directive conformance

Technical Specifications

- Dimensions: 2,400H × 1,200W × 600D mm (standard)

- Motor: 0.75kW absolute encoder type

- Voltage: 110-480V AC (configurable)

Why Choose Herochu?

Unlike competitive systems, our racks feature:

- Lifetime Structural Warranty

- No-Return-To-Origin Positioning

- Field-Reconfigurable Modules

Base configuration starts at $3,698 – Contact our engineering team for facility-specific layouts.